Construction method of cast-in-place drainage ditch

A construction method and drainage ditch technology, which can be applied to side ditches/curbs, roads, buildings, etc., can solve the problems of insufficient excavation capacity of special-shaped bucket excavators, concrete that is easy to leak vibration, and cumbersome problems, and achieve enhanced excavation Soil cutting ability, smooth and flat slope, and the effect of improving the quality of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the examples. The description of the following examples is provided only to aid the understanding of the present invention. It should be pointed out that for those skilled in the art, without departing from the principle of the present invention, some improvements and modifications can be made to the present invention, and these improvements and modifications also fall within the protection scope of the claims of the present invention.

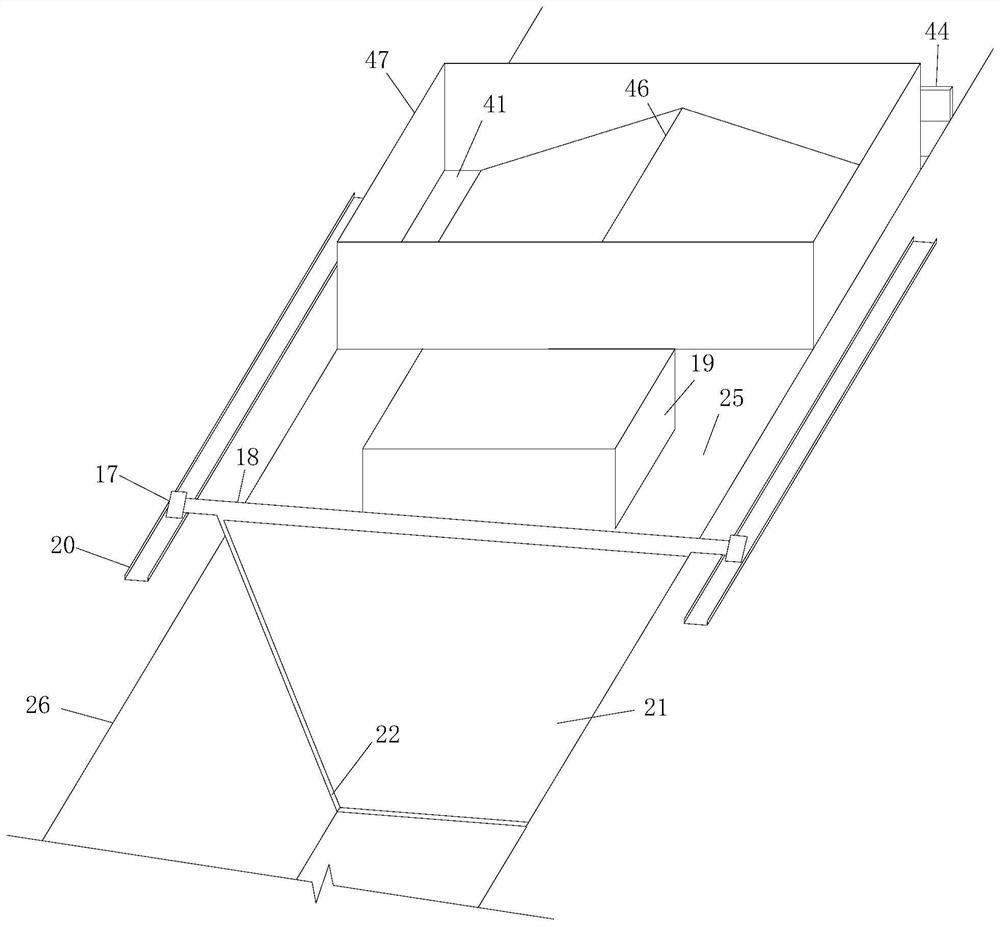

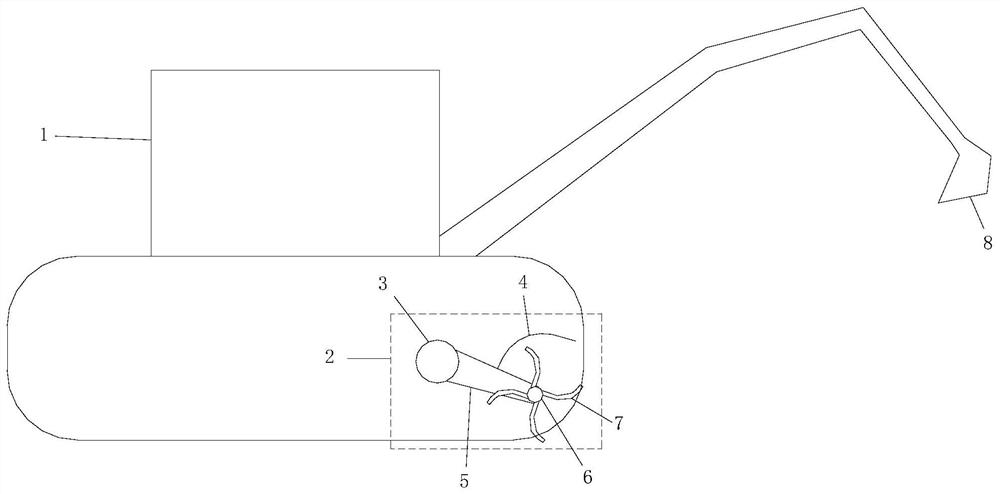

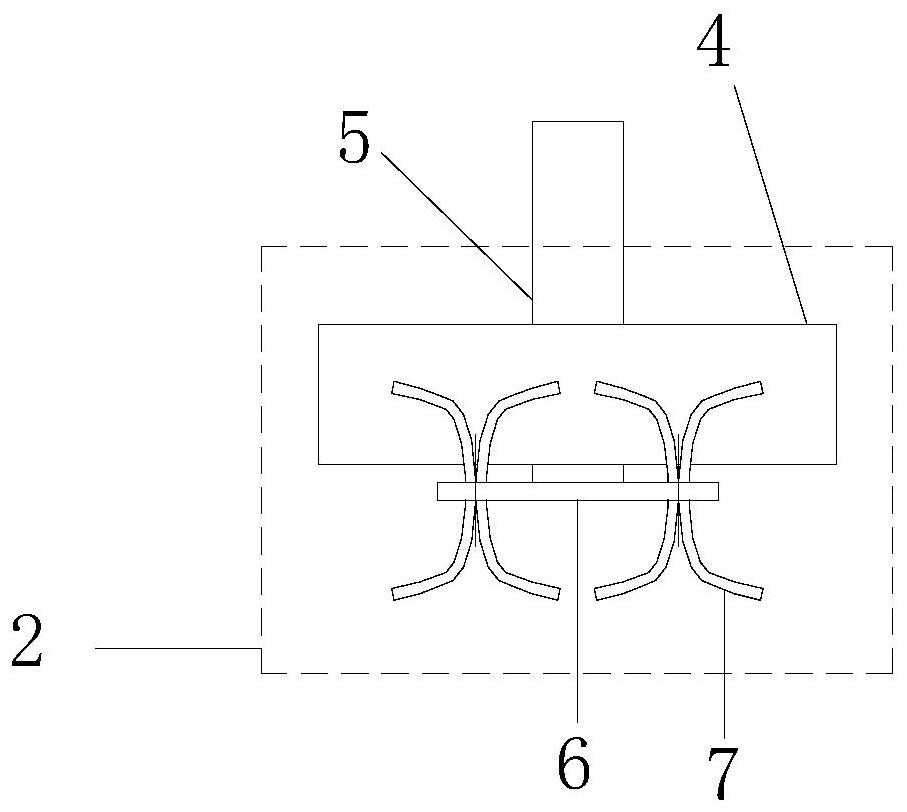

[0039] The construction method of the cast-in-place drainage ditch, according to the engineering design requirements, the drainage ditch construction equipment can cast-in-situ rectangular drainage ditch and trapezoidal drainage ditch, this patent only takes the construction method of the cast-in-situ trapezoidal drainage ditch as an example, including the following steps:

[0040] Step 1. According to the design size of the drainage ditch, select and assemble the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com