Rapid heading machine

A roadheader, fast technology, applied in mining equipment, earthwork drilling, tunnels, etc., can solve the problems that affect the safety of tunnel operations and project progress, low working efficiency and unsatisfactory flexibility of full-face rock roadheaders, etc., to achieve effective Conducive to geological map drawing and construction safety, fast excavation speed and high wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

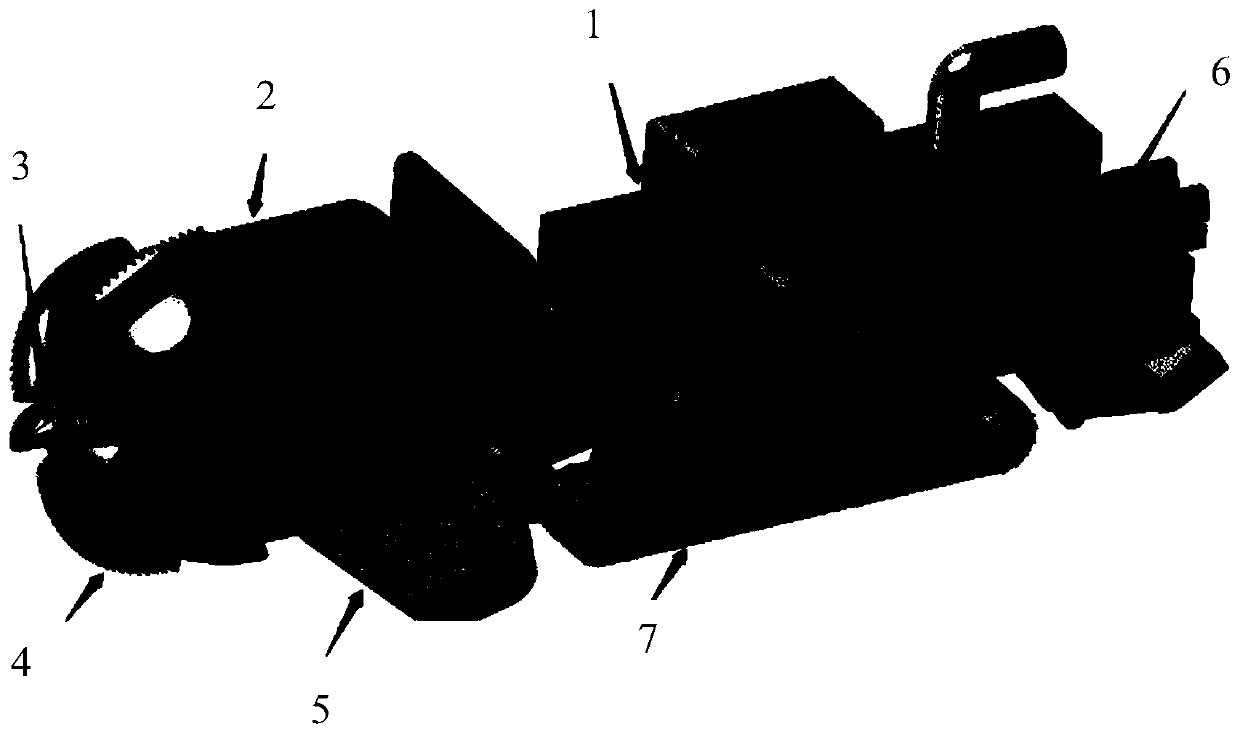

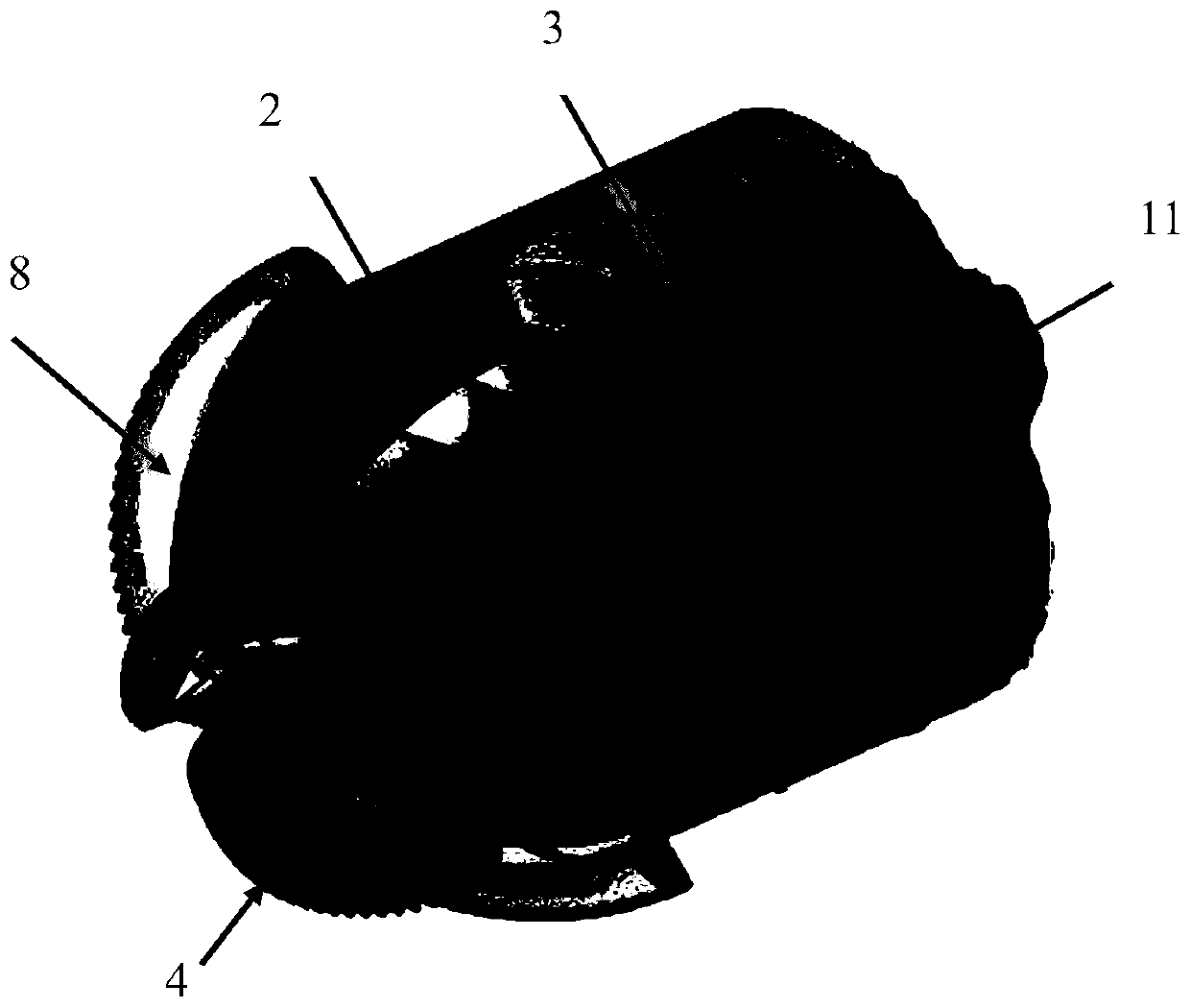

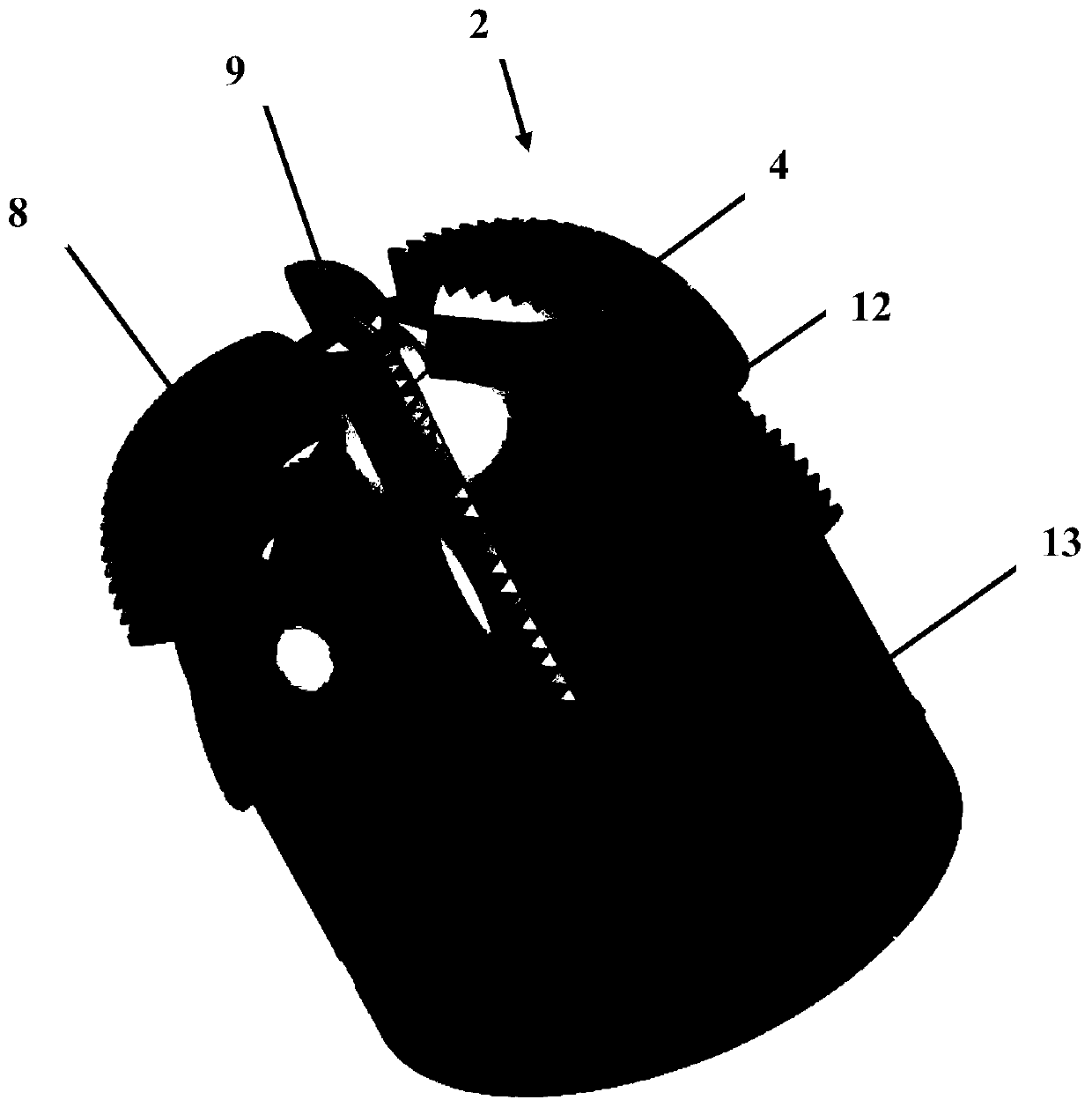

[0033] figure 1 and figure 2 It is a schematic diagram of the overall structure of the rapid roadheader of the present invention, and shows a perspective view of the partial structure of the cutter head and the spiral sandstone diverter of the roadheader. As shown in the figure, the roadheader adopts a crawler structure as a whole, and the crawler wheel 7 supports the entire roadheader. As a self-propelled roadheader, it can be deployed flexibly and conveniently when entering the site. During excavation, the crawler structure is used to apply pressure to facilitate the control of the entire excavation work; The cutter head 2 is erected on the driving wheel 11 in front; the excavation cutter head 2 is a hollow cone with an opening at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com