Electric power inspection method and system based on unmanned aerial vehicle

An electric power inspection and unmanned aerial vehicle technology, applied in control/regulation systems, radiation pyrometry, non-electric variable control, etc., can solve problems such as difficulty, inaccurate power inspection results, and multiple human resources. The effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

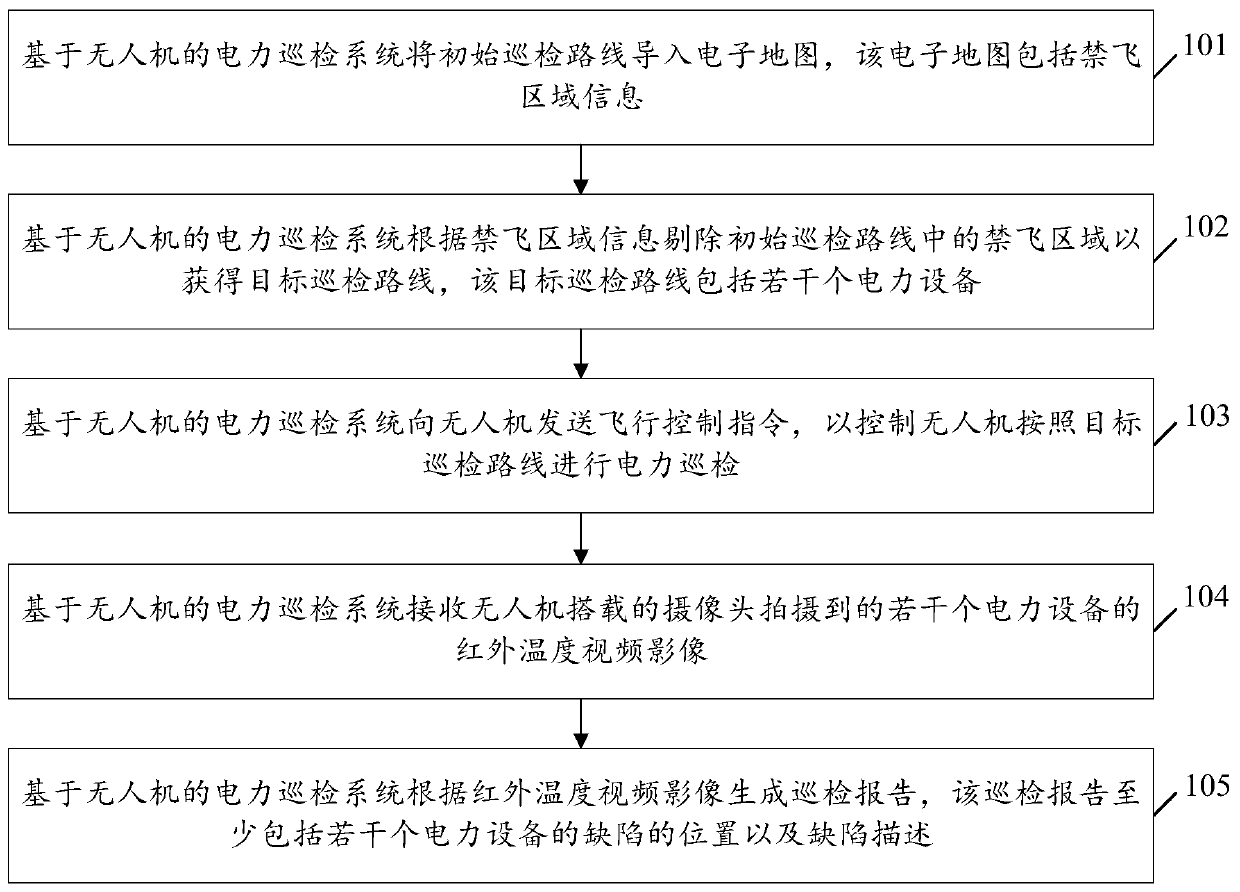

[0075] see figure 1 , figure 1 It is a schematic flow chart of a UAV-based power inspection method disclosed in an embodiment of the present invention. Such as figure 1 As shown, the UAV-based power inspection method may include the following steps.

[0076] 101. The UAV-based power inspection system imports the initial inspection route into an electronic map, and the electronic map includes information on no-fly areas.

[0077] In the embodiment of the present invention, the above-mentioned UAV-based power inspection system may include UAVs, mobile devices, servers and other hardware devices; where UAVs can be equipped with infrared cameras, visible light cameras and / or laser radars, etc. , the mobile device can be configured with applications for flight control as well as data management.

[0078] It can be understood that the UAV-based power inspection system imports the initial inspection route into the electronic map, which can realize the preview of the initial inspe...

Embodiment 2

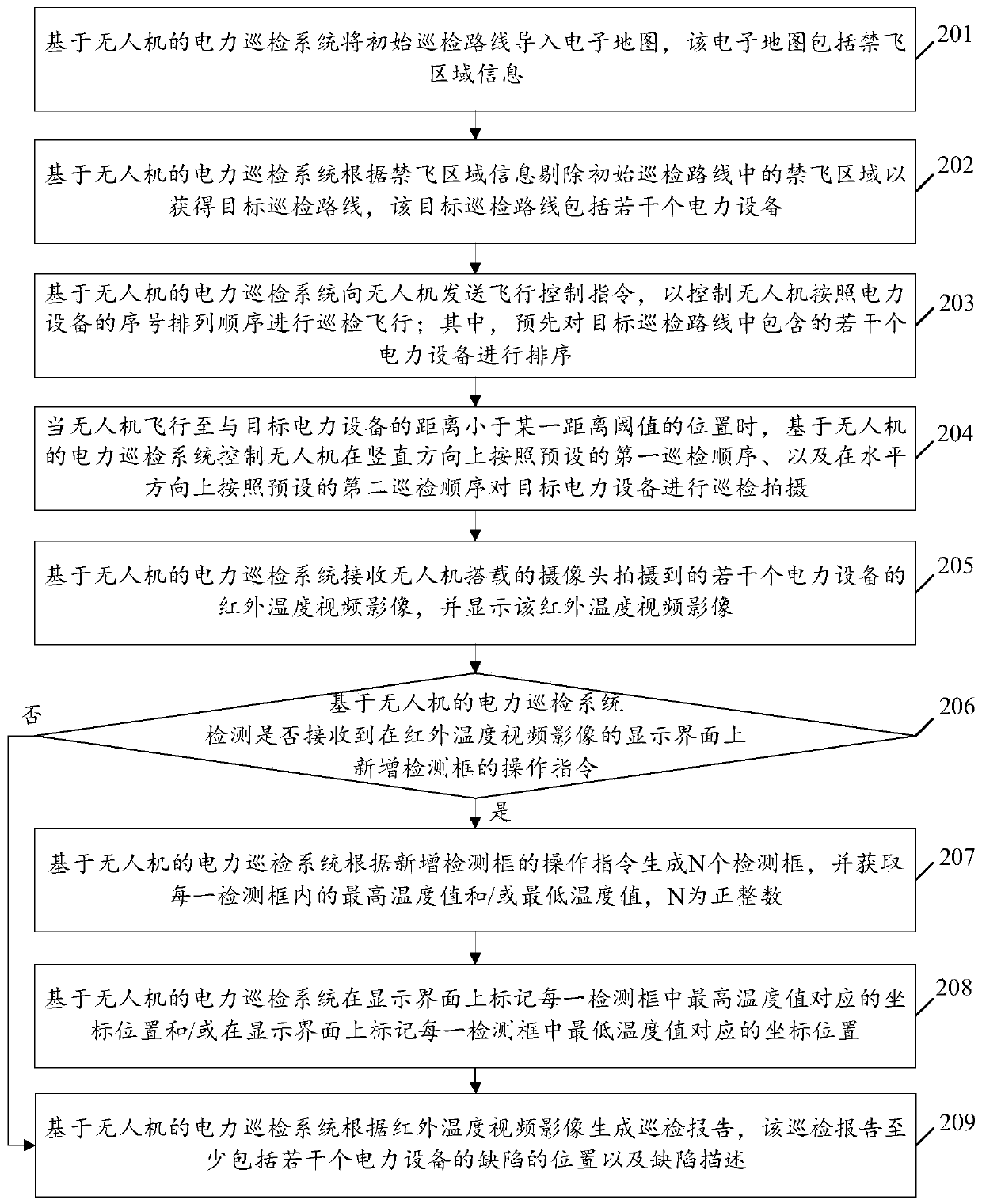

[0094] see figure 2 , figure 2 It is a schematic flow chart of another unmanned aerial vehicle-based power inspection method disclosed in the embodiment of the present invention. Such as figure 2 As shown, the UAV-based power inspection method may include the following steps.

[0095] 201. The UAV-based power inspection system imports the initial inspection route into an electronic map, where the electronic map includes information on no-fly areas.

[0096] 202. The UAV-based power inspection system eliminates no-fly areas in the initial inspection route according to the no-fly area information to obtain a target inspection route, and the target inspection route includes several electric devices.

[0097] 203. The UAV-based power inspection system sends flight control instructions to the UAV to control the UAV to perform inspection flights according to the order of the serial numbers of the power equipment; Electrical devices are sorted.

[0098] In the embodiment of t...

Embodiment 3

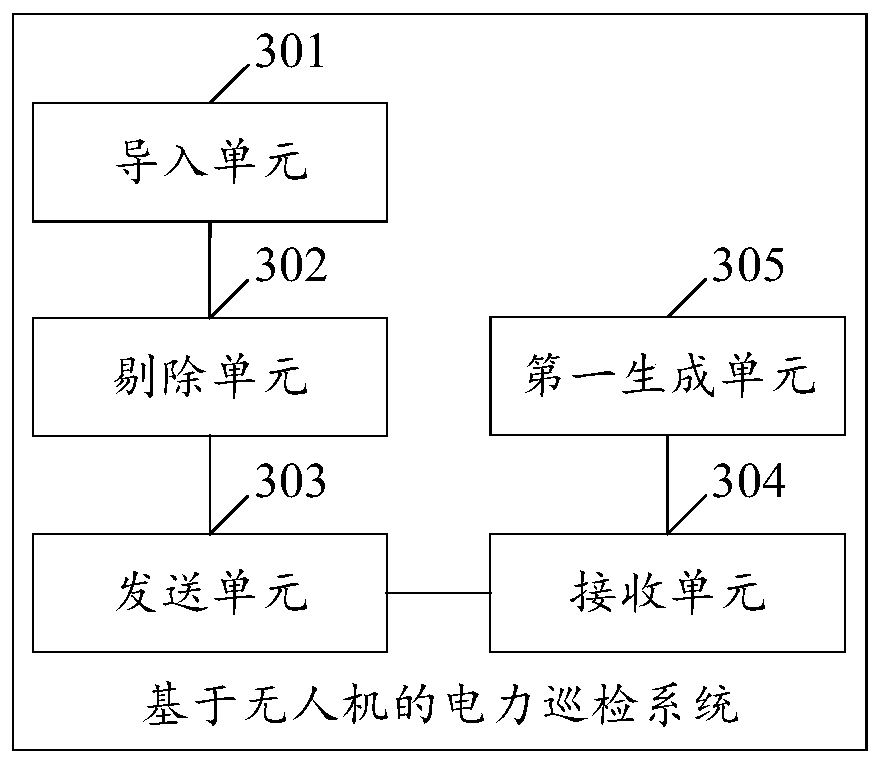

[0123] see image 3 , image 3 It is a schematic structural diagram of an unmanned aerial vehicle-based power inspection system disclosed in an embodiment of the present invention. Such as image 3 As shown, the UAV-based power inspection system can include:

[0124] The import unit 301 is used to import the initial inspection route into the electronic map, and the electronic map includes no-fly area information;

[0125] The elimination unit 302 is used to eliminate the no-fly area in the initial inspection route according to the no-fly area information to obtain the target inspection route, and the target inspection route includes several electric devices;

[0126] The sending unit 303 is configured to send flight control instructions to the UAV, so as to control the UAV to perform power inspection according to the target inspection route;

[0127] The receiving unit 304 is used to receive the infrared temperature video images of several electric devices captured by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com