Biotrickling filter of coating production line waste gas

A technology of biological trickling filter and coating production line, which is applied in the direction of air quality improvement, dispersion particle separation, chemical instruments and methods, etc. It can solve problems such as plugging fillers, microbial growth and shedding, and slow biological treatment effect, achieving fast efficiency, The effect of reducing clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

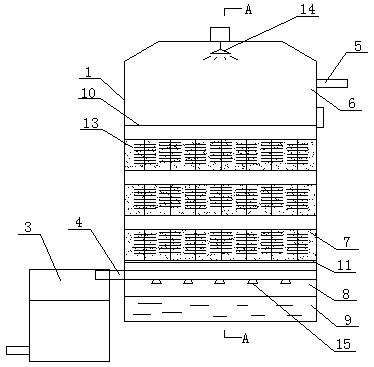

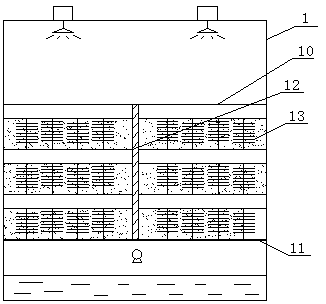

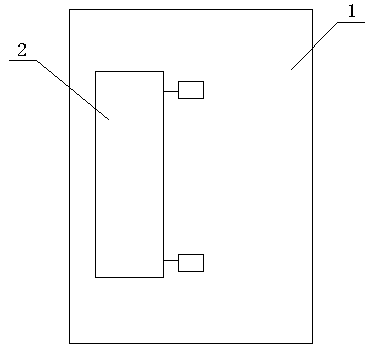

[0025] Such as Figure 1-4 The illustrated biological trickling filter for waste gas from a coating production line includes a biological trickling filter body 1 . The pool body of the biological trickling filter adopts concrete pouring, and the top of the pool body is provided with a spray pool 2, and the top inside of the biological trickling filter is provided with a spray pipe 14, and the spray pipe is connected to the spray pool. One side of the pool body is provided with a humidification box 3; the air intake pipe is connected to the humidification box. The air inlet pipe is first connected to the humidification box, and after humidification, it enters the biological trickling filter for treatment, so that the gas is in contact with the liquid, increasing the volume and weight of the gas, and making the subsequent gas stay in the filler for a long time. The other side of the pool body is provided with a fan. One side of the lower part of the pool body communicates with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com