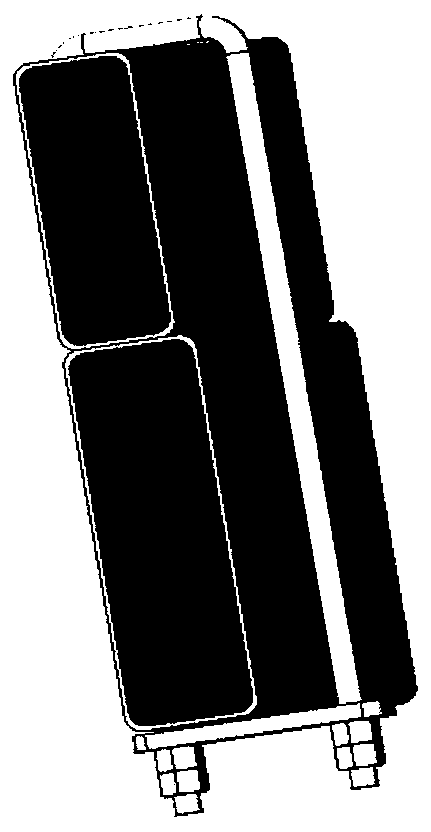

Manufacturing process for high-strength square U-shaped bolts

A manufacturing process and high-strength technology, applied in the field of mechanical processing, can solve the problems of high cost and low processing efficiency of high-strength square U-shaped bolts, and achieve the effects of saving costs, optimizing the manufacturing process, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The manufacturing process of the present invention will be described in detail below in conjunction with specific embodiments.

[0018] The following takes the 40Cr material of the curved inner angle R10 as an example to illustrate a high-strength square U-shaped bolt manufacturing process. The inventive method comprises the following steps:

[0019] (1) Car threading, this step can be processed according to the drawings by using a common lathe, and the problem of high labor intensity, low processing efficiency and high manufacturing cost of the operator in the tapping process of using special tools in the existing method can be effectively solved by this step;

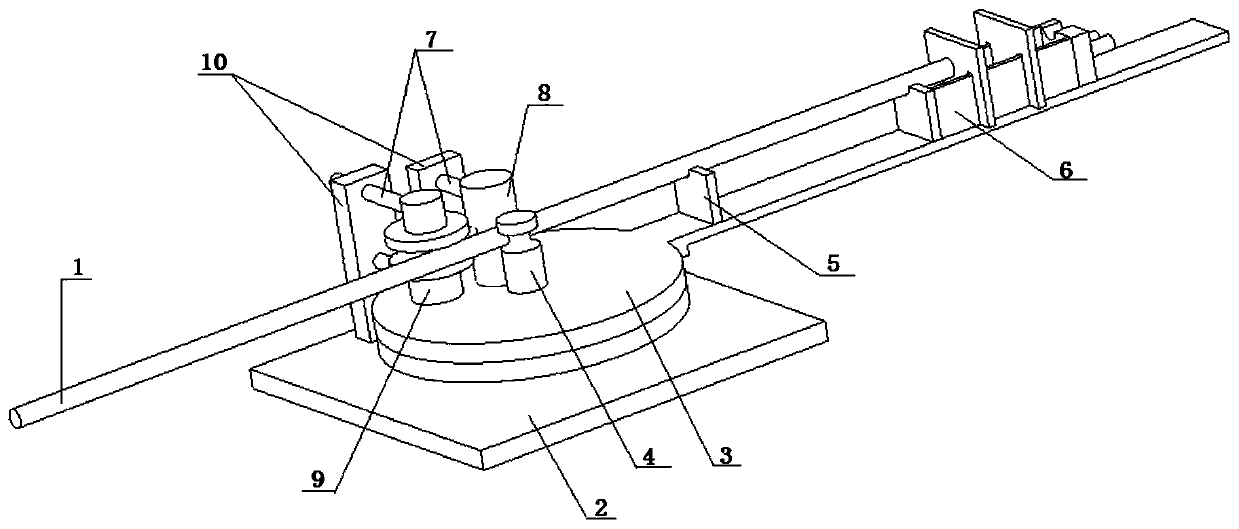

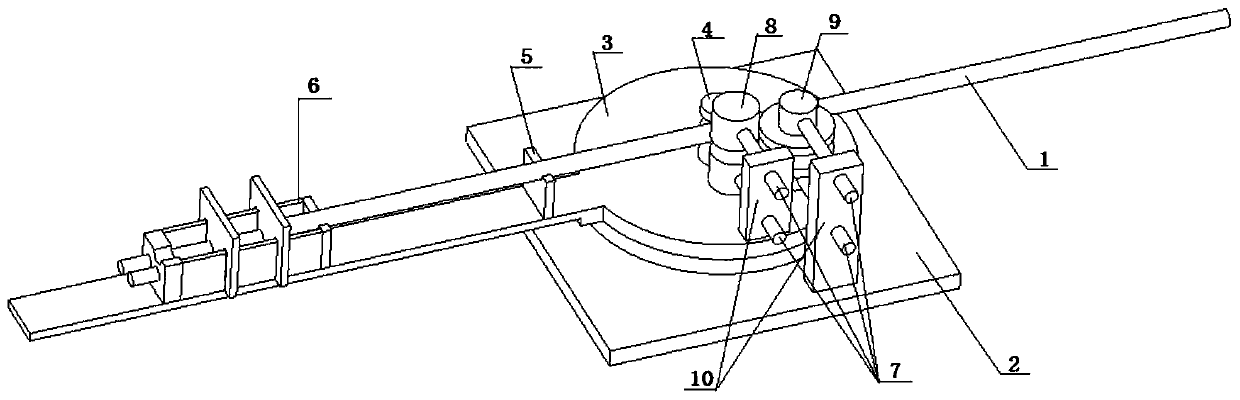

[0020] (2) heating and bending;

[0021] In this step, the existing bending forming method can be used to bend the part into a square U shape meeting the specification requirements;

[0022] Preferably, the following process can be used to achieve: on both sides of the corner center of the part Range heating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com