Vehicle thermal management system suitable for new energy vehicle under low-temperature working condition

A new energy vehicle and management system technology, applied in the field of new energy vehicle thermal management system, can solve problems such as high-end, aggravated thermal runaway risk and safety risk, and excessive internal resistance of the battery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the following embodiments will specifically illustrate the new energy vehicle thermal management system of the present invention, which is suitable for low temperature conditions, in conjunction with the accompanying drawings.

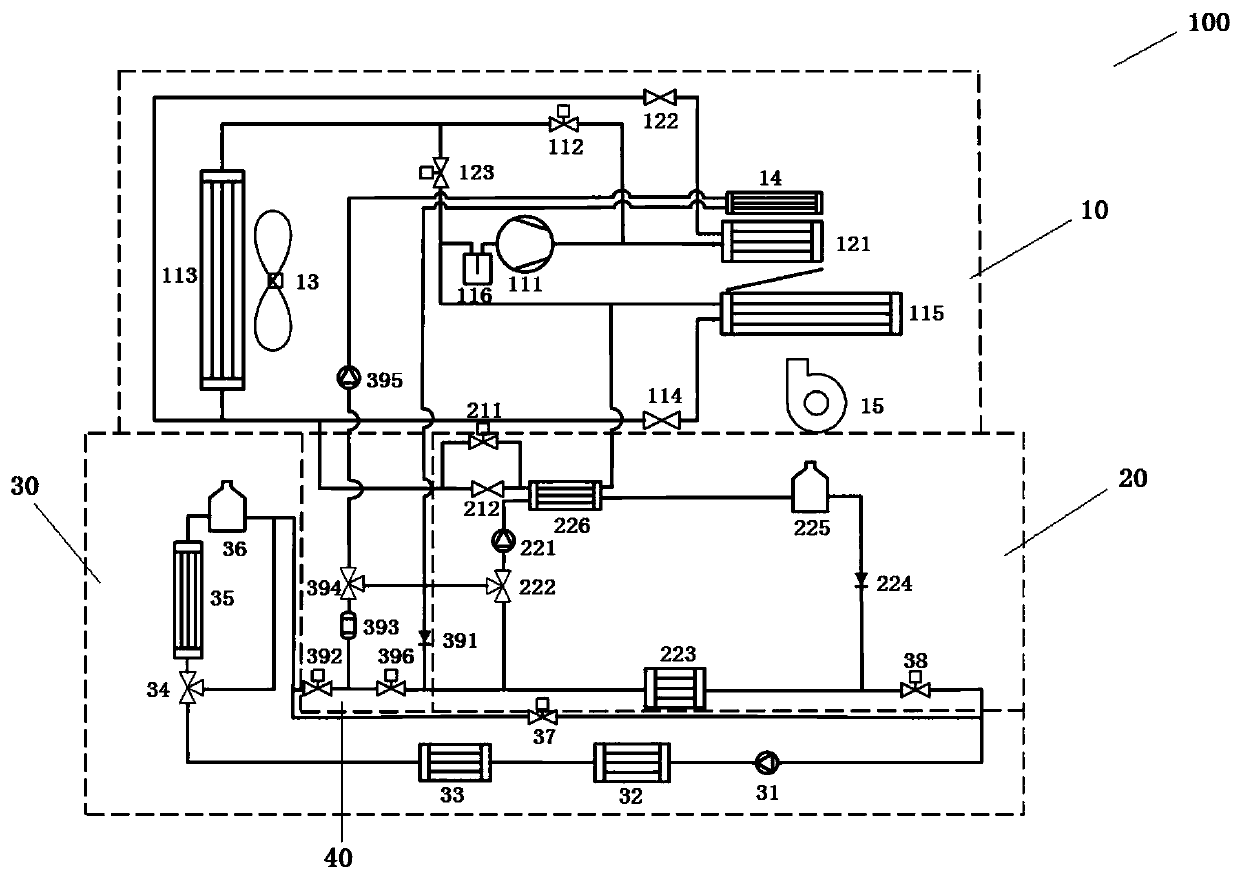

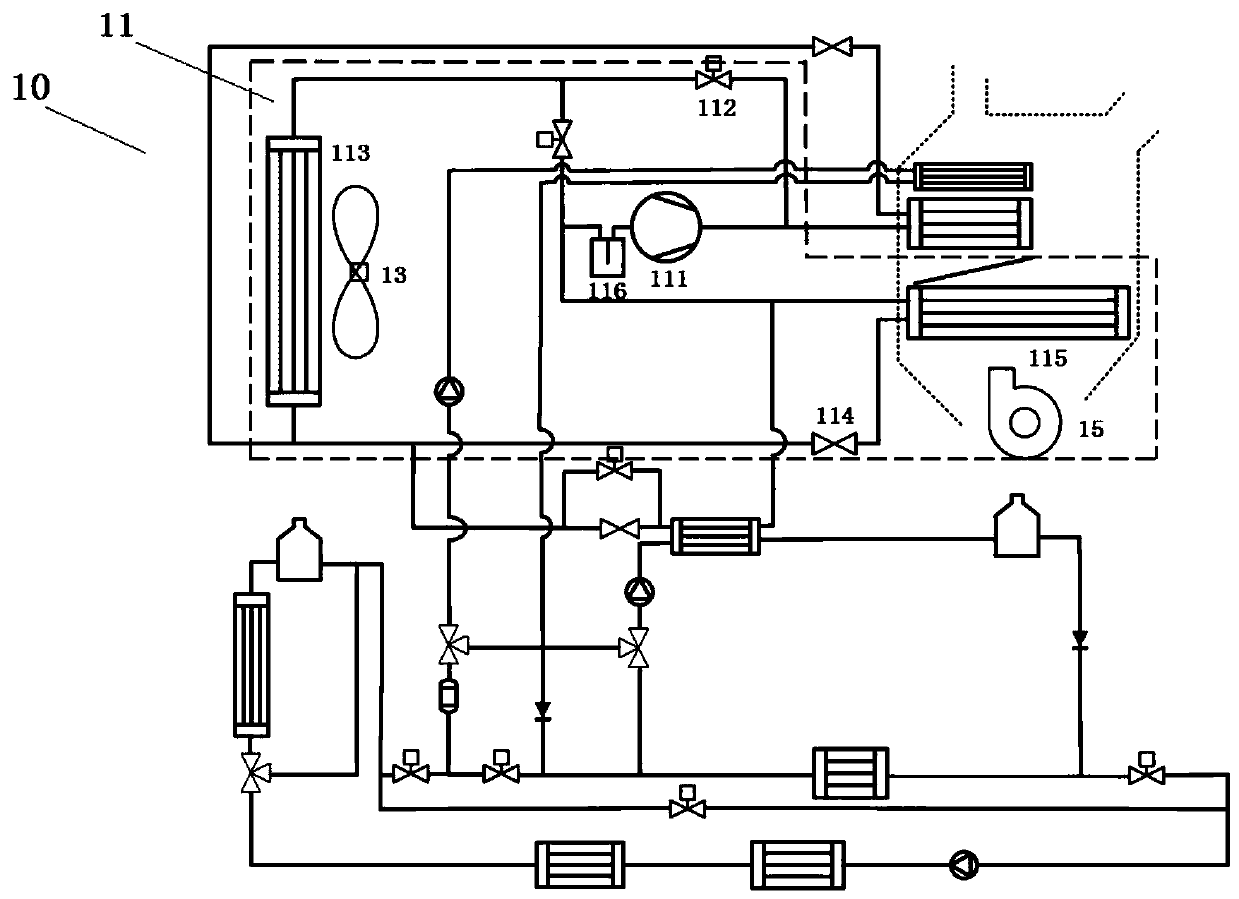

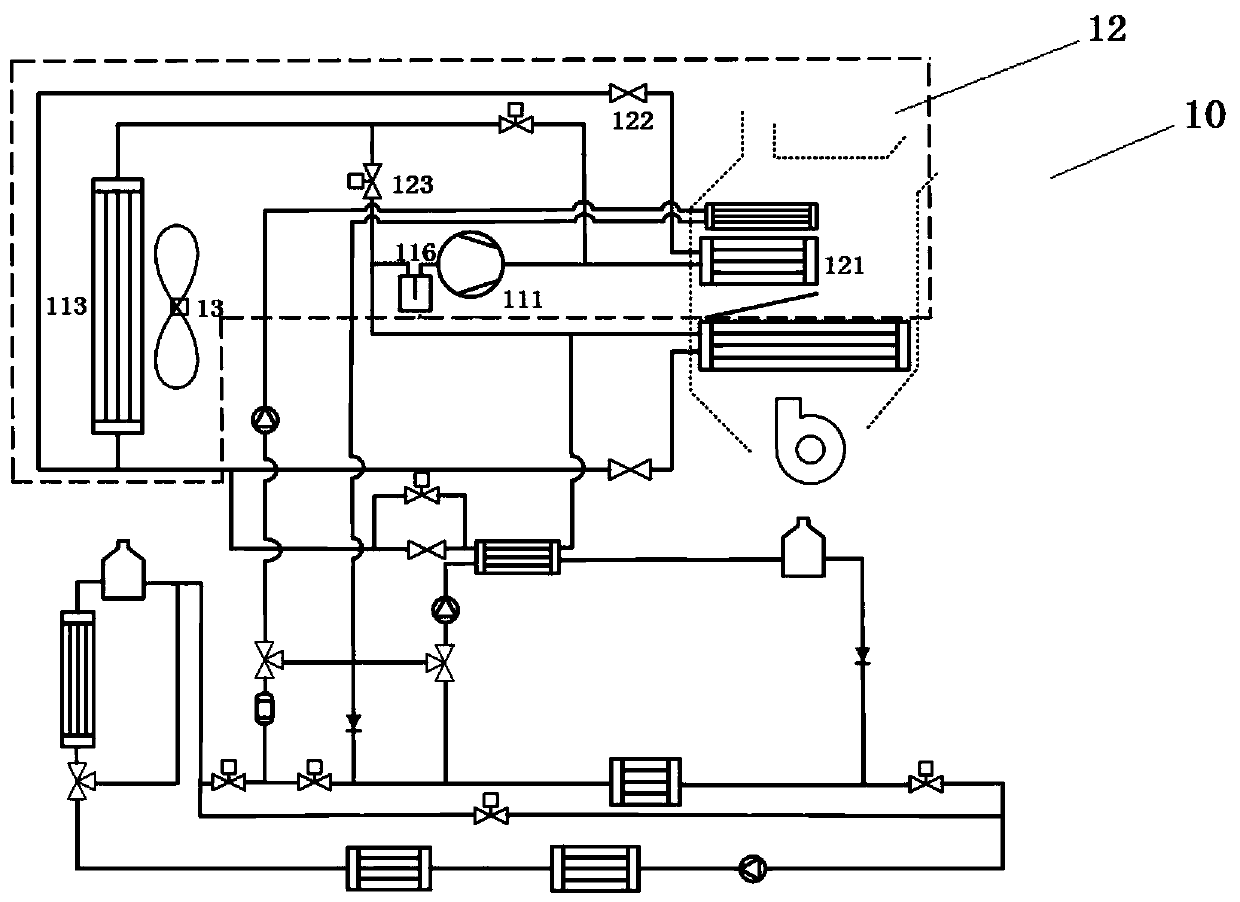

[0028] figure 1 It is a schematic diagram of the overall system of the thermal management system of the new energy vehicle in the embodiment of the present invention.

[0029] Such as figure 1 As shown, the new energy vehicle thermal management system 100 suitable for low temperature conditions in this embodiment includes: passenger compartment thermal management system 10, battery thermal management system 20, motor electronic control thermal management system 30 and water PTC electric heating management system 40 .

[0030] The passenger compartment thermal management system 10 includes a passenger compartment refr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap