Coal gangue-based microporous concrete, heat-preserving composite wallboard and preparation methods thereof

A coal gangue concrete and thermal insulation composite technology, which is applied to ceramic products, other household appliances, applications, etc., can solve the problems of poor thermal insulation function of walls, single usage of coal gangue, and increased production process, so as to save energy, save processes, Reduce the effect of volume shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

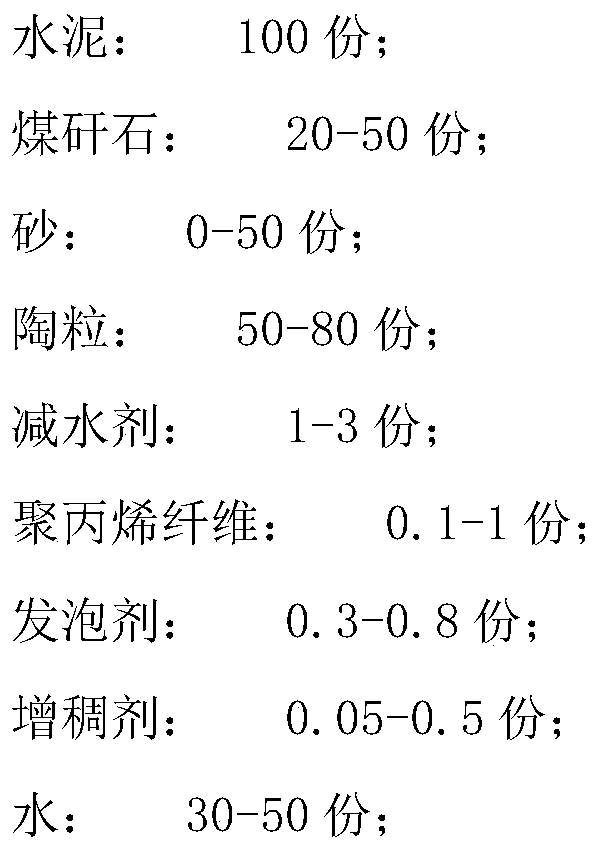

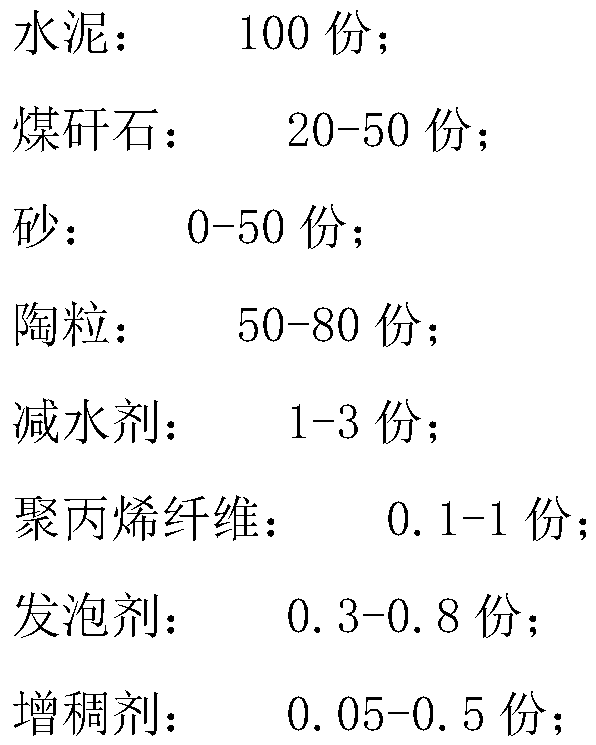

Method used

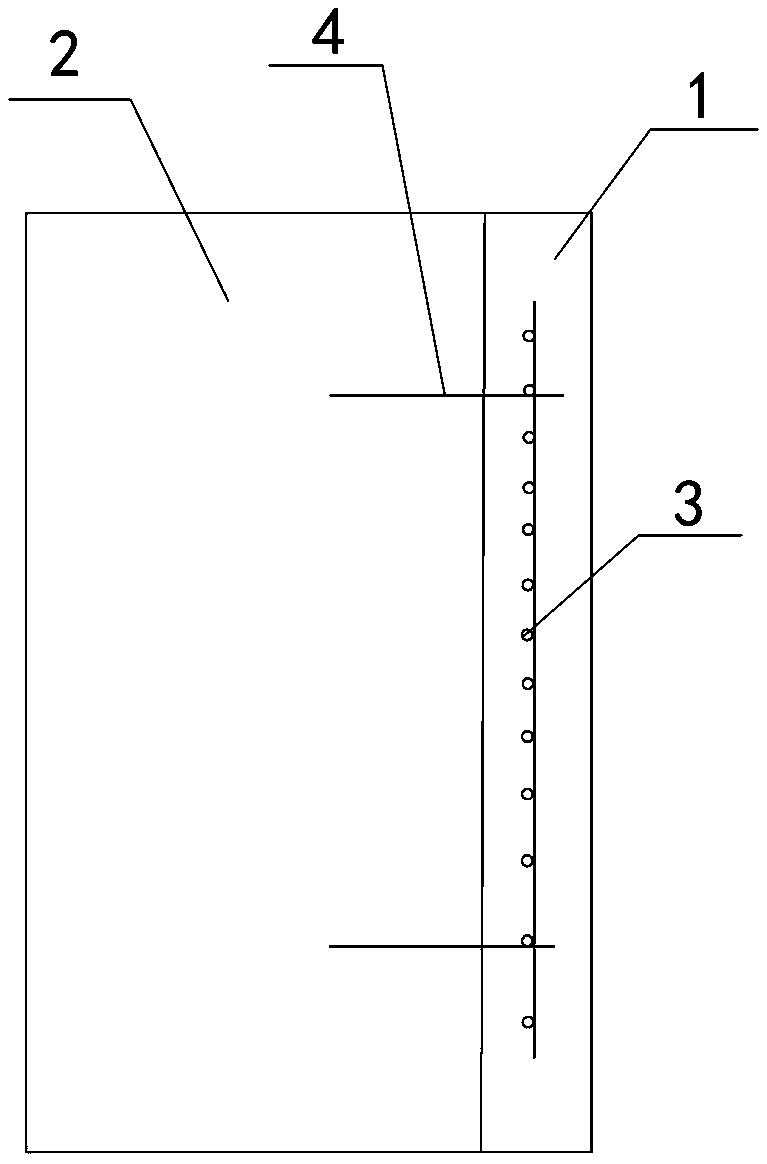

Image

Examples

Embodiment

[0060] Crush the gangue until the particle size is less than 30 mm, and screen the gangue particles to obtain coal gangue particles with a particle size of 5 mm to 30 mm, which are used to make the aggregate of ordinary gangue concrete layer 1, and mix according to the raw materials in Table 1. Ratio Weigh the raw materials for preparing common gangue concrete, and calculate according to parts by weight.

[0061] Prepare ordinary gangue concrete as follows:

[0062] Step 1. Add the raw materials into the mixer in the following order: stone coarse aggregate, coal gangue coarse aggregate, machine-made sand, cement, fly ash, water, and water reducing agent.

[0063] Step 2. Stir for about 5 minutes.

[0064] Table 1. Raw materials and proportions of ordinary gangue concrete

[0065]

[0066] The chemical composition of coal gangue is SiO 2 : 40%~70%, Al 2 o 3 : 10%~30%, Fe 2 o 3 : ≤6%, CaO: ≤10%, MgO: ≤2%.

[0067] Prepare the mold and reinforcement, pour the prepared ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com