A dual-frequency adjustable Helmholtz muffler cavity for a vehicle engine

A vehicle engine, muffler cavity technology, applied to engine components, machines/engines, mechanical equipment, etc., can solve the problems of wasted structure space, inconsistent frequency of noise peaks, poor axial motion transient response characteristics, etc. Reasonable use, low inertia, and wide coverage of the frequency range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further explained below in conjunction with the accompanying drawings.

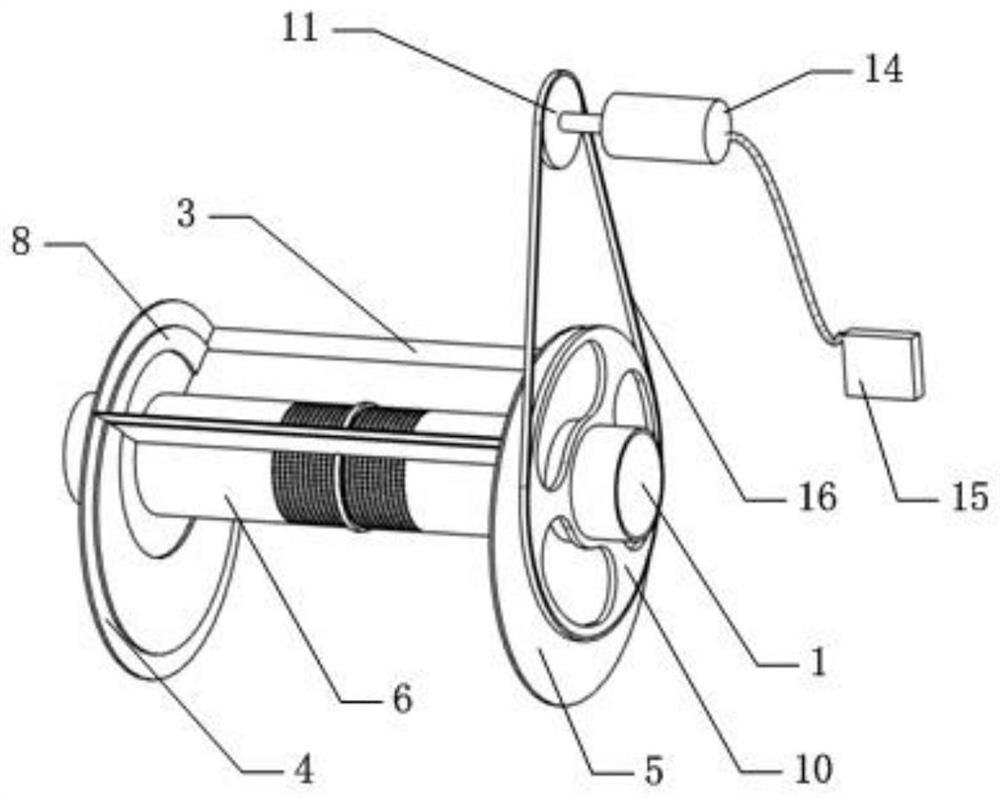

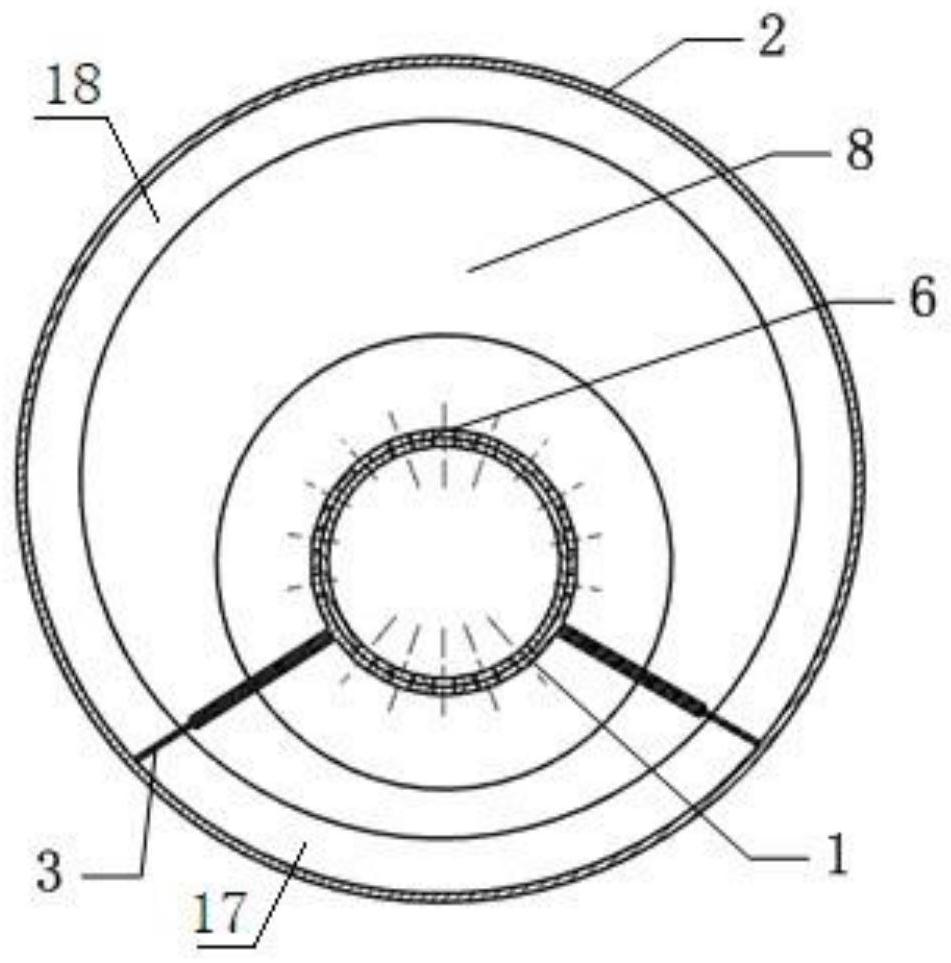

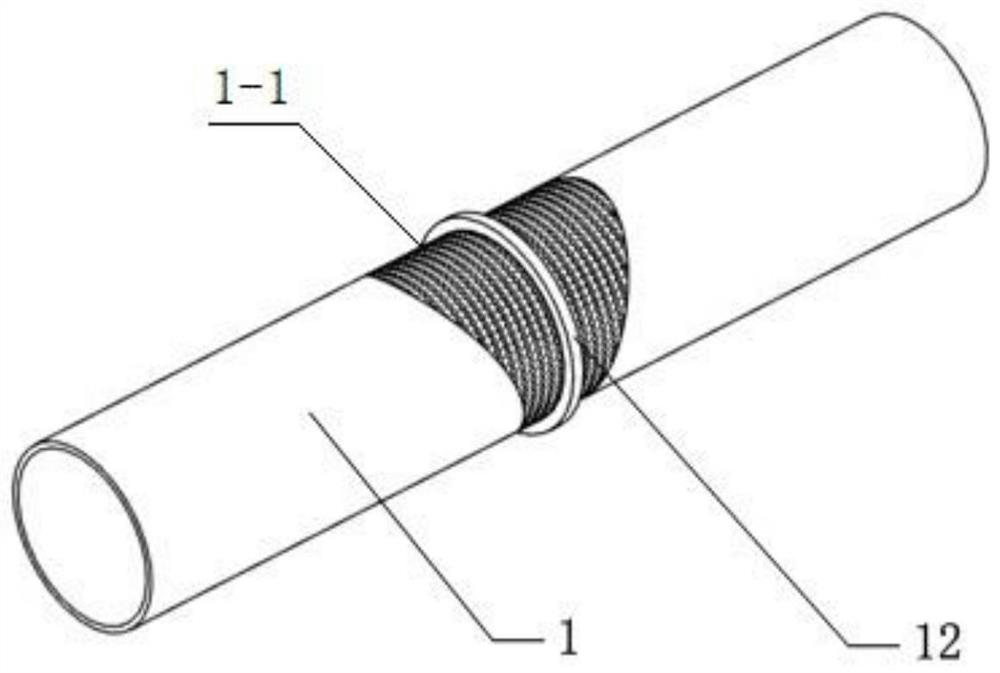

[0031] Such as figure 1 and 2 As shown, a dual-frequency adjustable Helmholtz muffler cavity of a vehicle engine of the present invention includes a perforated pipe 1, an outer pipe 2, telescopic blades 3, a front end cover 4, a rear end cover 5, and a rotating sleeve 6 , Volume adjustment device.

[0032] The rotating sleeve 6 is set on the outside of the perforated tube 1, the inner diameter of the rotating sleeve 6 matches the outer diameter of the perforated tube 1, the outer tube 2 is set on the outer side of the rotating sleeve 6 and is set eccentrically with the rotating sleeve 6, and the front end cover 4 is set on the outer tube 2, the rear end cap 5 is arranged at the other end of the outer tube 2, and an eccentric annular cavity is formed between the rotating sleeve 6, the outer tube 2, the front end cover 4, and the rear end cap 5.

[0033] Such as ima...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com