A rainproof textile fabric drying equipment

A technology for textile fabrics and equipment, which is applied in the field of rain-proof textile fabric drying equipment, can solve problems such as pollution and erosion of large quantities of textile fabrics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

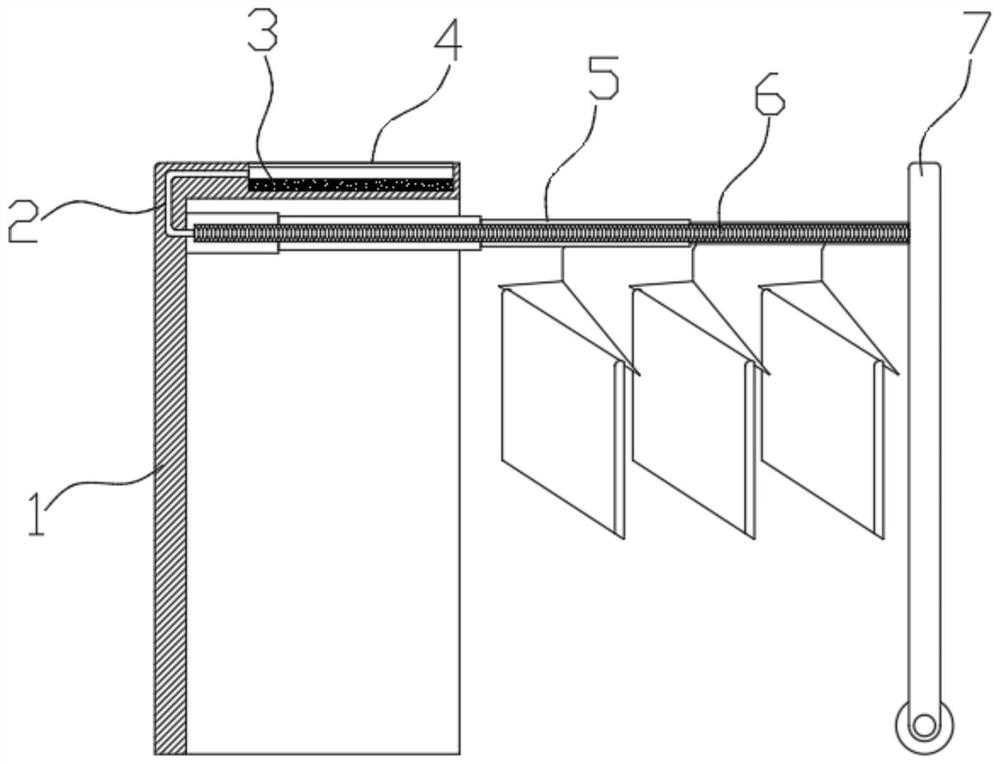

[0021] refer to figure 1 , a rainproof textile fabric drying equipment, the drying equipment includes a shell 1 with an opening on one side, the inner wall of the shell 1 is fixedly connected with a drying rod 5 that can expand and contract in the horizontal direction, and the drying rod 5 is a multi-stage telescopic rod. The telescopic end of the drying rod 5 is fixedly connected with a support baffle 7 .

[0022] The housing 1 is also provided with a driving mechanism for driving the extension of the drying rod 5. The driving mechanism includes a telescopic air bag 6 arranged in the drying rod 5. The telescopic end of the telescopic air bag 6 is fixed to the telescopic end of the drying rod 5. The casing 1 The upper end surface of the upper surface of the liquid storage tank 3 is provided with a convex lens 4, and the liquid storage tank 3 is provided with a low boiling point evaporation liquid, and the telescopic air bag 6 communicates with the liquid storage tank 3 through...

Embodiment 2

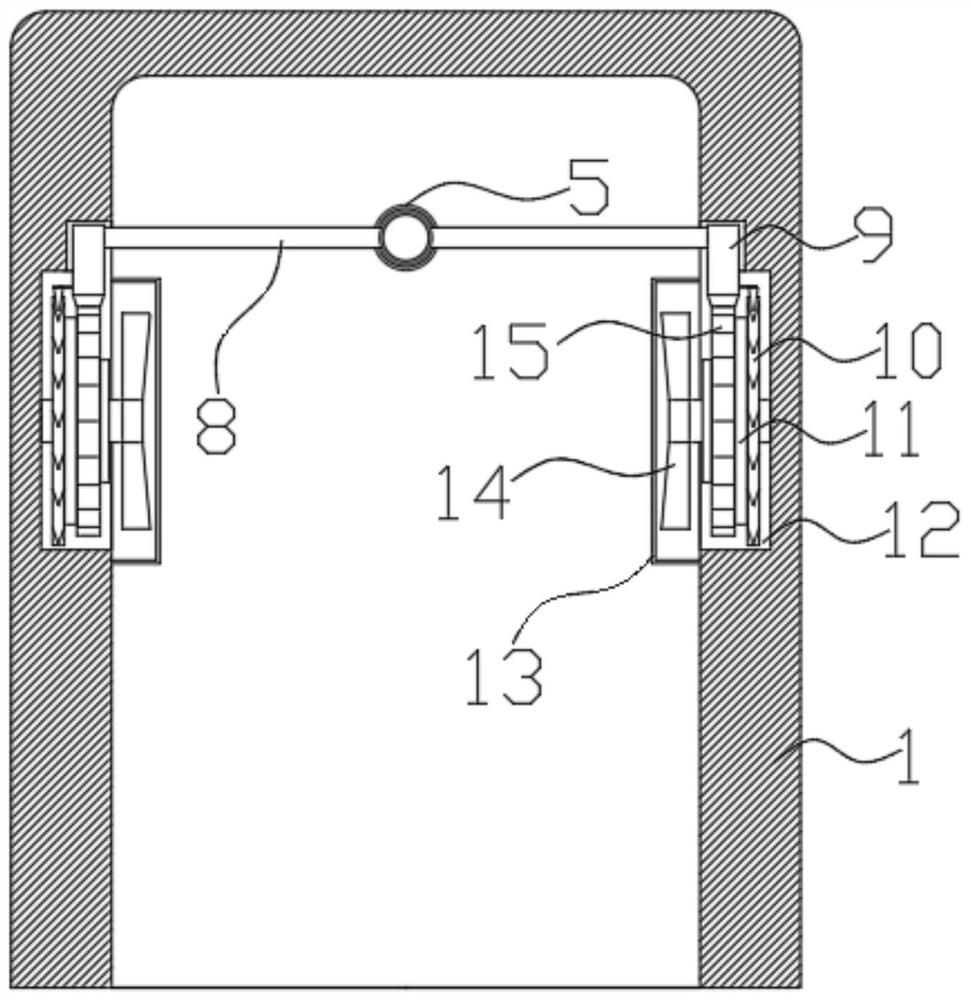

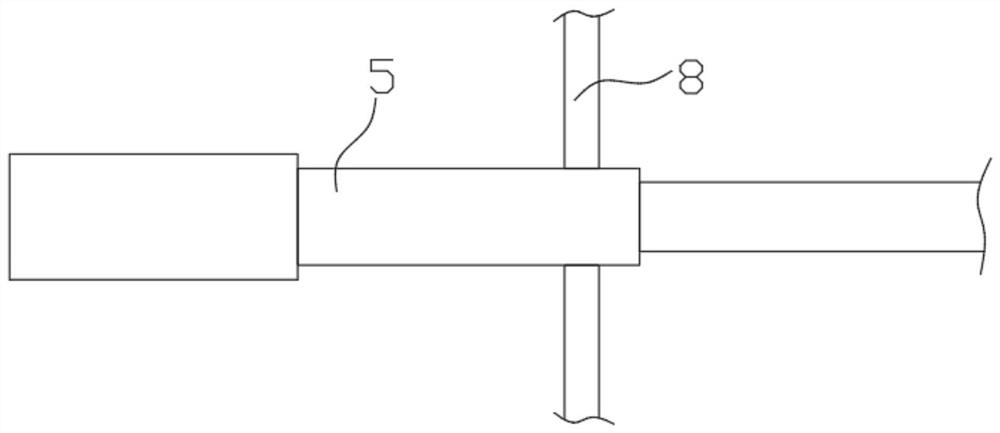

[0025] refer to Figure 2-3 , different from Embodiment 1, the opposite inner wall of the housing 1 is provided with a device groove 12, and the notch of the device groove 12 is provided with a fan blade 14, and the fan blade 14 is connected to the inner wall of the device groove 12 through a rotating shaft. , a coil spring 11 is installed on the rotating shaft, and the outer end of the coil spring 11 is fixedly connected on the inner wall of the device groove 12, and a gear 15 is also installed on the rotating shaft, and the inner top of the device groove 12 is slidably connected with a rack meshed with the gear 15 9. The rack 9 is fixedly connected to the drying rod 5 through the connecting rod 8, a ratchet 10 is installed on the rotating shaft, and a pawl is installed in the device groove 12, and when the drying rod 5 is extended to the limit position, the rack 9 moves The ratchet locks the ratchet 10, and the notch of the device groove 12 is provided with a protective cove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com