LSTM-based gas turbine online detection method and apparatus

A gas turbine and detection method technology, which is applied in gas turbine engine testing, jet engine testing, neural learning methods, etc., can solve problems such as large prediction errors and control effects, and achieve high accuracy, large data volume, and small analysis errors. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

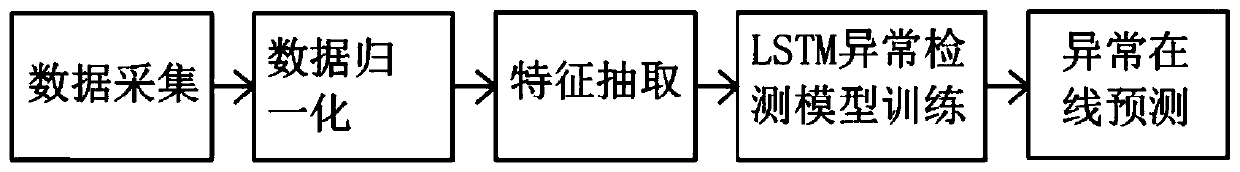

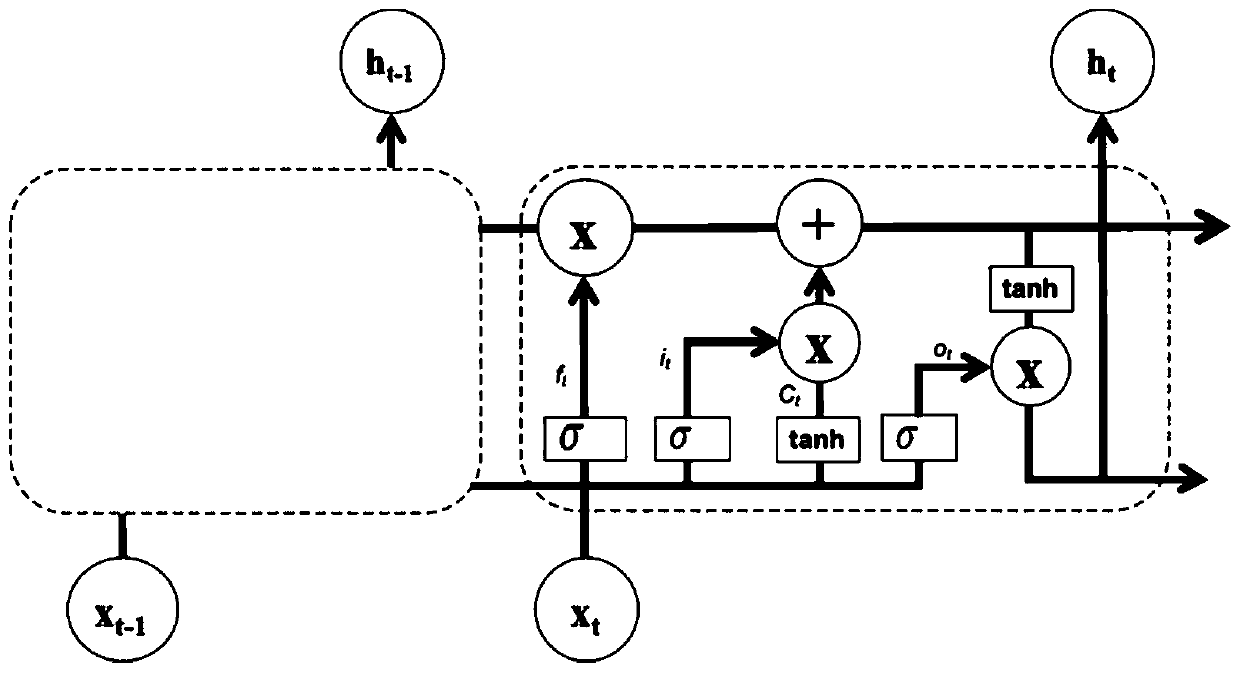

[0046] Such as Figure 1-3As shown, the proposed LSTM-based gas turbine anomaly online detection method and device include the following steps:

[0047] Step 1: Data collection. A gas turbine is mainly composed of three major components: a compressor, a combustor and a turbine. Select the main measuring point data from the monitoring software of the gas turbine, and analyze it as the input of the LSTM neural network. Measuring point data include: GT IGV position (angle), GT IGV position, air humidity, gas turbine compressor intake temperature, gas turbine intake filter differential pressure measurement point (1) and measurement point (2), gas turbine intake filter Internal pressure, gas turbine inlet static pressure, GT IGV position-1 measuring point (1) and measuring point (2), gas turbine compressor inlet temperature measuring point (1), measuring point (2) and measuring point (3), Gas turbine compressor outlet air temperature, gas turbine combustor shell pressure measuri...

Embodiment 2

[0077] An LSTM-based gas turbine online detection device with the above method installed, including a memory, a processor, an I / O device and an alarm device that are electrically connected and stored with a program for realizing the above method, and the I / O device is connected to a computer with monitoring software installed on the gas turbine and / or network to access and obtain real-time measurement point data.

[0078] The processor is connected to the hand-held user terminal through wireless transmission. Remote monitoring and early warning through handheld devices.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com