Thin type full automatic adhesive tape winding machine head and device and method therefor

A fully automatic, tape technology, applied in electrical components, manufacturing wiring harnesses, circuits, etc., can solve problems such as the inability to meet the requirements of this process, achieve good results, realize automatic production, and improve the overall manufacturing level.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further elaborated and illustrated below in conjunction with the accompanying drawings and specific embodiments.

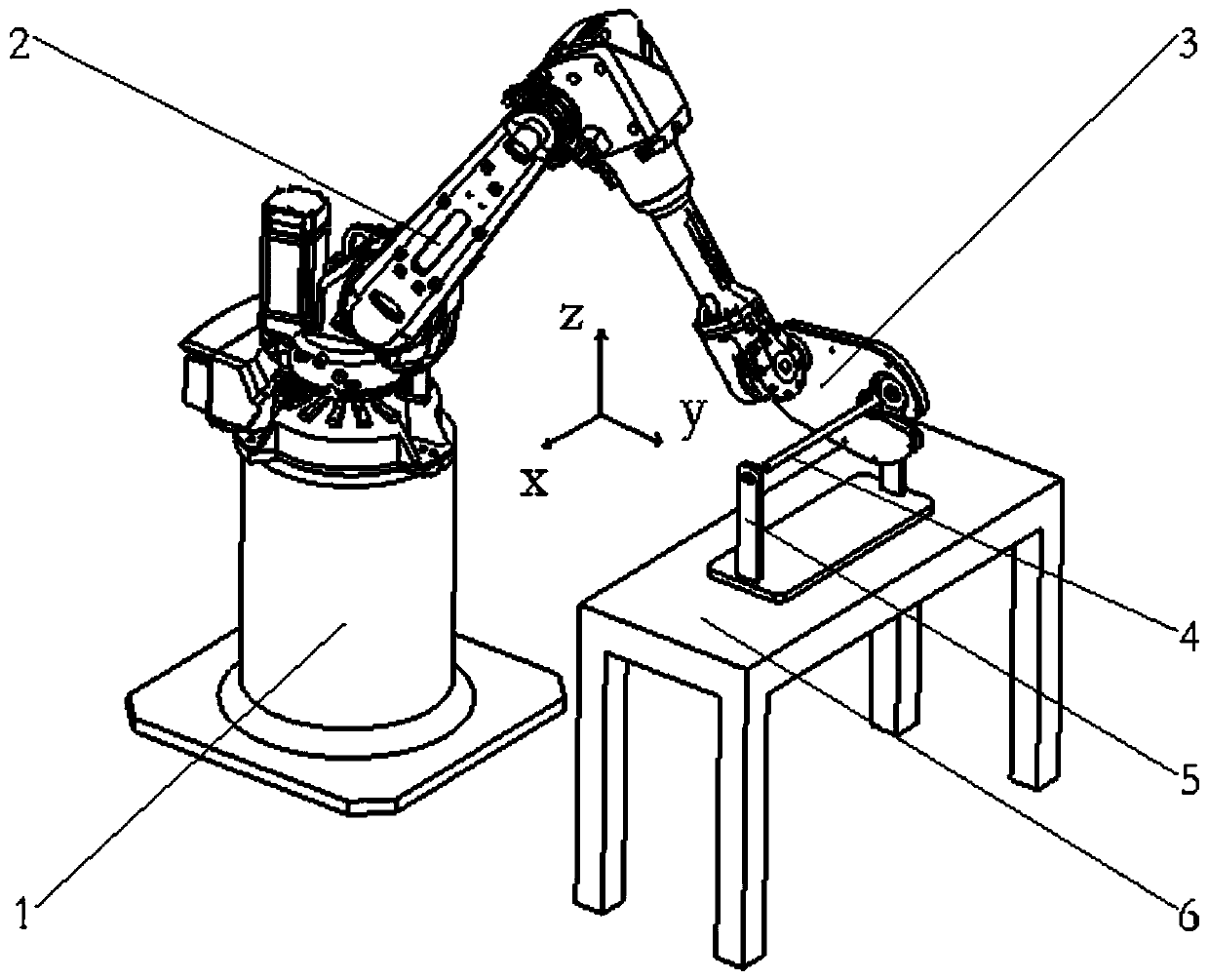

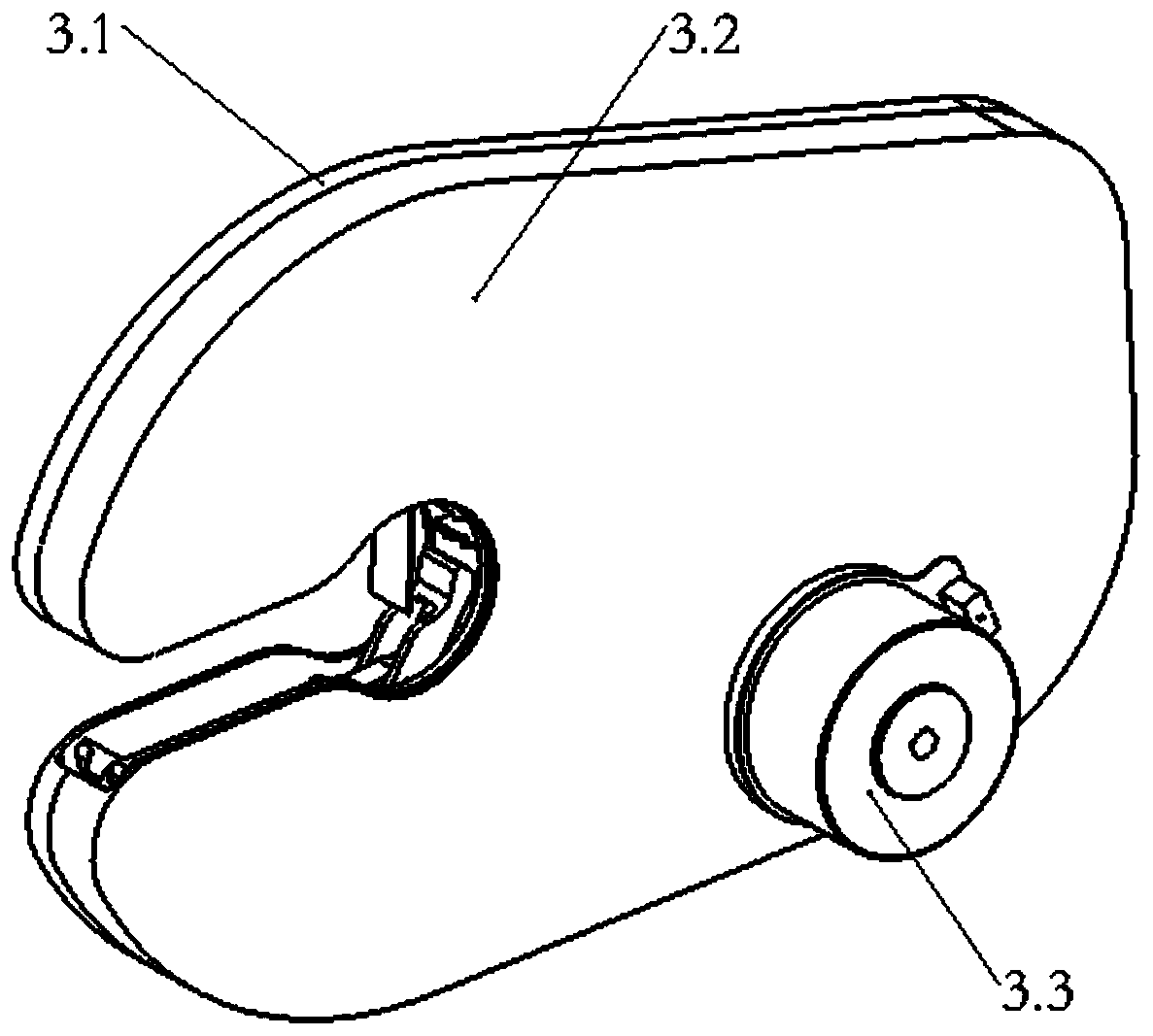

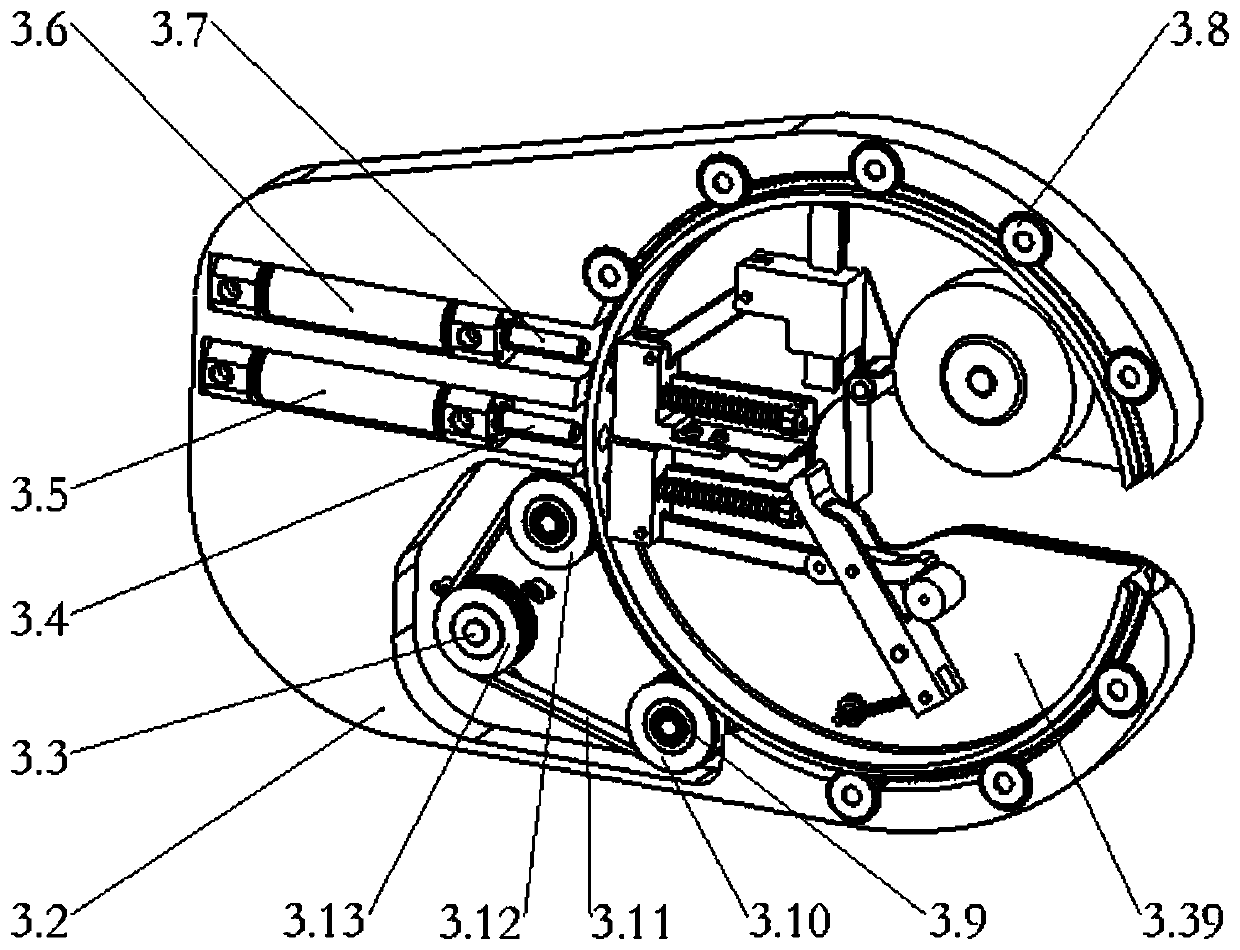

[0049] As shown in Figure-1, a thin automatic tape winding equipment is designed in a preferred embodiment of the present invention, mainly including base 1, robot 2, machine head 3, wire harness 4, fixture 5, workbench 6 and other components .

[0050] Wherein, the base 1 is a metal structural part, which is fixed on the ground by fasteners, and is mainly used for installing the robot 2 .

[0051] In this embodiment, the robot 2 is a multi-degree-of-freedom polar coordinate manipulator, which is mainly used to control the working trajectory and posture of the head 3 . However, it should be noted that the robot 2 in the present invention should be understood in a broad sense, and any device capable of controlling the working trajectory and attitude of the head 3 can be used. For example, it can also be replaced by other types ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com