Polishing rod used for machining slotted hole and polishing method

A polishing rod and waist-shaped hole technology, applied in metal processing equipment, grinding/polishing equipment, manufacturing tools, etc., can solve the problems of leaving very obvious grinding marks, complicated production procedures, and uncontrollable polishing effects. Achieve the effects of reducing capital investment and space occupation, excellent mirror effect, and reducing dust pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

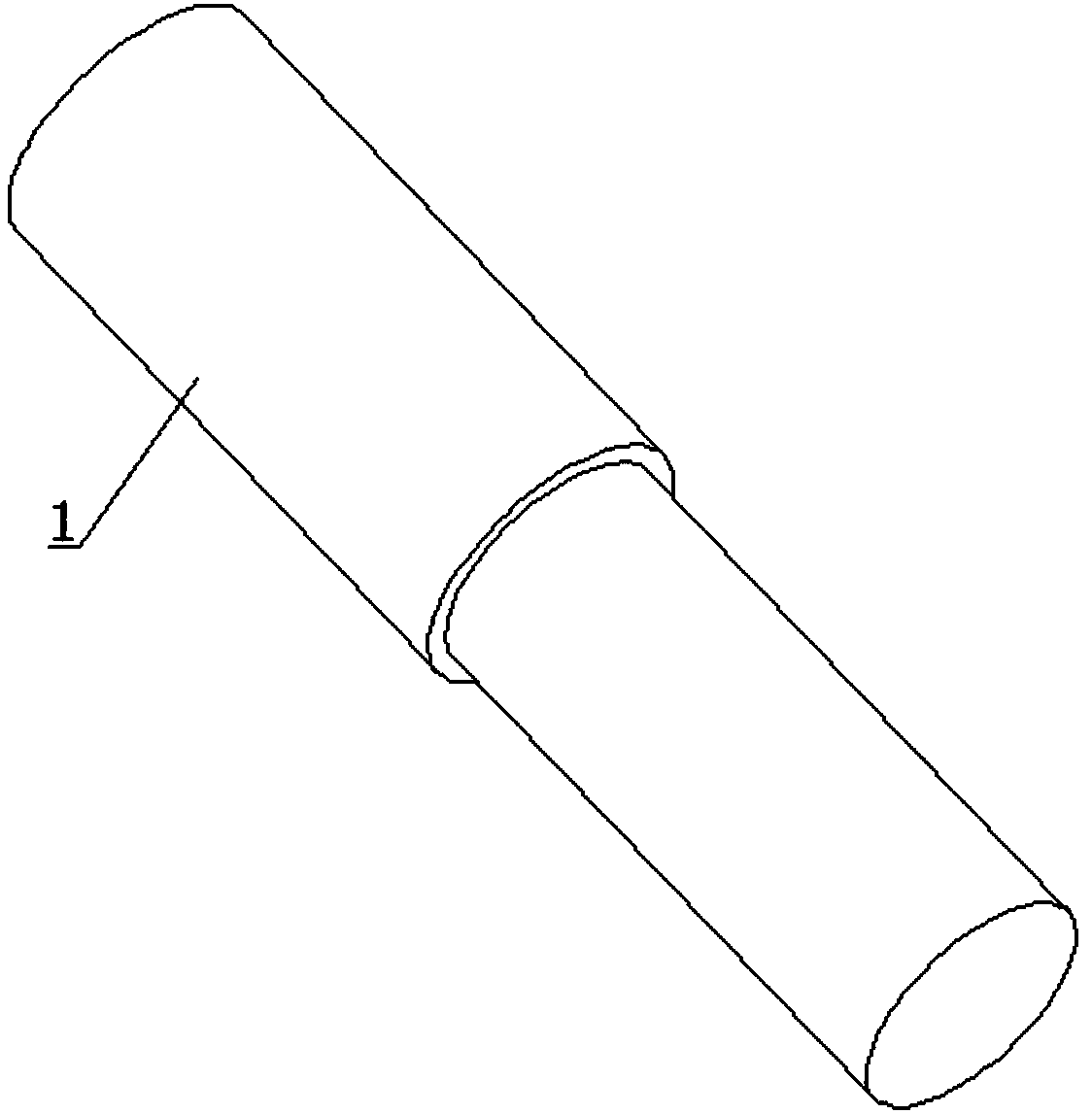

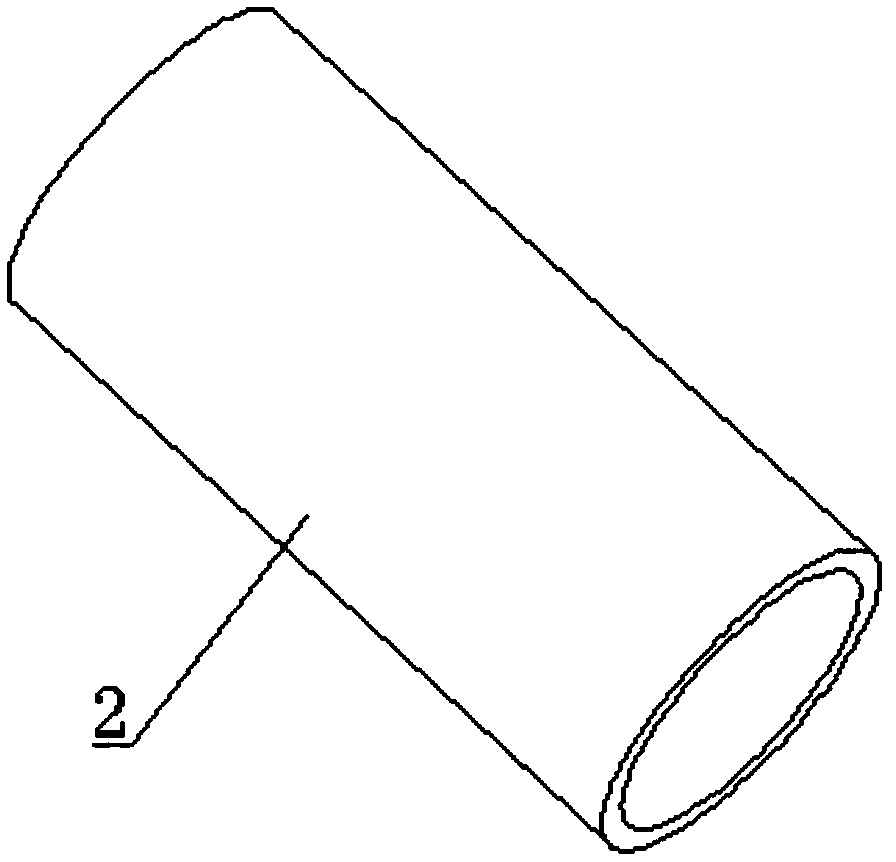

[0037] see Figure 1-Figure 6 , a polishing rod for processing waist-shaped holes, comprising a metal rod body 1 whose upper end is fixedly connected to a CNC machining shaft, a latex tube sleeve 2 sleeved at the lower end of the metal rod body 1, and wrapped in the latex tube Set of 2 exterior buffing microdermabrasion3.

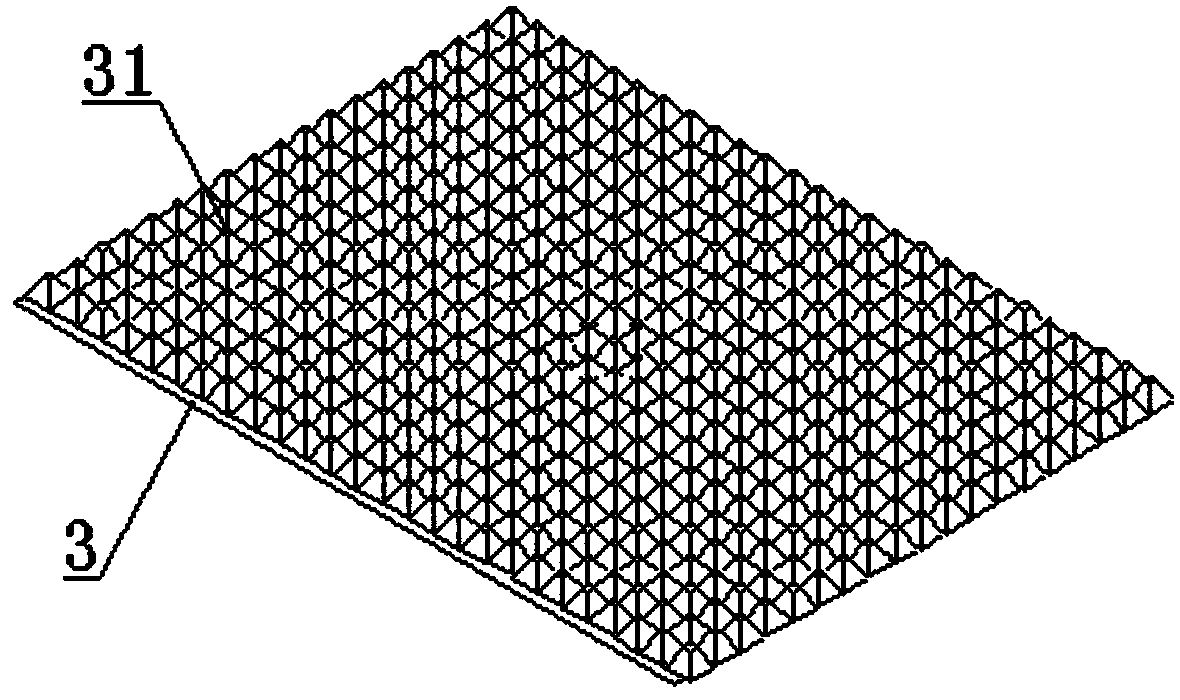

[0038] A plurality of tiny cones 31 are arranged on the outer surface of the polishing skin 3 , and the cones 31 have a quadrangular pyramid structure and are arranged in a linear array. In this embodiment, the bottom of the cone 31 is a square of 2mm×2mm and its height is 1.5mm. The angle between two adjacent edges at the top of the cone 31 is 25°. The distance between the sides of the bottom of the cone is 2.1mm.

[0039] In this embodiment, the axial length of the polishing buffing skin 3 is 10 times the depth of the waist hole 01, correspondingly, the buffing buffing skin 3 is divided into 10 annular processing areas in the direction of its axial leng...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com