Preparation method of fully soluble dextrin

A dextrin and solubility technology, applied in the field of preparation of fully soluble dextrin, can solve the problems of dextrin being easily soluble in hot water and poor solubility, and achieve the effects of broadening the scope of application, uniform molecular chain and high total solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

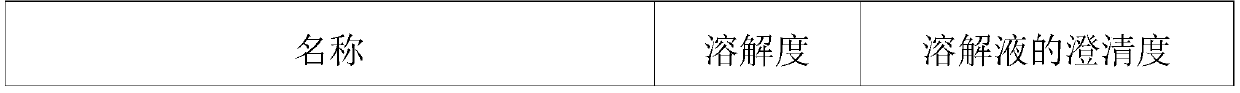

Image

Examples

Embodiment 1

[0025] (1) Add water to 1000g dry potato starch to make 22 Baume starch milk, raise the temperature and keep the temperature at 35°C, add 10g of α-amylase, keep the pH value at 5.0, and stir for 1 hour for enzymatic hydrolysis.

[0026] (2) Adjust the pH value of the above-mentioned starch milk after enzymolysis to 8.5 with sodium hydroxide, and then add vinyl acetate to react for 2 hours. During this period, do not add or add additional amount of vinyl acetate to control the acetyl content of 0.6%, and then pump Dehydration is filtered, the solid is washed twice with water, dried, and crushed to obtain modified potato starch.

[0027] (3) Add dilute nitric acid with a concentration of 10% to the potato enzymatically modified starch by spraying, fully mix, and adjust the pH value to 2.0.

[0028] (4) Put the material in an oven, heat up to 120° C., and react for 2.5 hours to obtain 920 g of dextrin on an absolute dry basis that meets the requirement of complete dissolution.

Embodiment 2

[0030] (1) Add water to 1000g dry potato starch to make 23 Baume starch milk, raise the temperature and keep the temperature at 40°C, add 20g of α-amylase, keep the pH value at 5.5, and stir for 1 hour for enzymatic hydrolysis.

[0031] (2) Adjust the pH value of the above-mentioned reduced starch milk to 8.5 with sodium hydroxide, add vinyl acetate to react for 2 hours, adjust the amount of vinyl acetate added, control the acetyl group content to 1.5, dehydrate by suction filtration, and wash the solid with water twice Dried and crushed to obtain potato enzymatically modified starch.

[0032] (3) Add dilute hydrochloric acid with a concentration of 10% to the potato enzymatically degraded starch by spraying, fully mix, and adjust the pH value to 2.5.

[0033] (4) Put the material in an oven, heat up to 130° C., and react for 4 hours to obtain 910 g of dextrin on an absolute dry basis that meets the requirement of full solubility.

Embodiment 3

[0035] (1) Add water to 1000g of absolute dry potato starch to make 24 Baume starch milk, raise the temperature and keep the temperature at 45°C, add 15g of α-amylase dropwise, keep the pH value at 6.0 during the dropwise addition, and stir for 30 minutes .

[0036] (2) Use sodium hydroxide to adjust the pH value of the above-mentioned starch milk to 8.7, add vinyl acetate to react for 2 hours, adjust the amount of vinyl acetate added, control the acetyl group content to 2.0, dehydrate by suction filtration, and wash the solid with water twice Dried and crushed to obtain potato enzymatically modified starch.

[0037] (3) Add dilute hydrochloric acid with a concentration of about 5% to the potato enzymatically degraded starch by spraying, fully mix, and adjust the pH value to 2.8.

[0038] (4) Put the material in an oven, heat up to 150° C., and react for 3.5 hours to obtain 900 g of dextrin that meets the requirement of full solubility.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com