Construction method for super maintenance sealing layer of cement concrete pavement

A cement concrete and construction method technology, applied in the direction of roads, roads, road repairs, etc., can solve the problems of long construction time, road traffic interference, long cement concrete setting time, etc., to achieve short setting time, super flexibility, The effect of repairing the effect is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

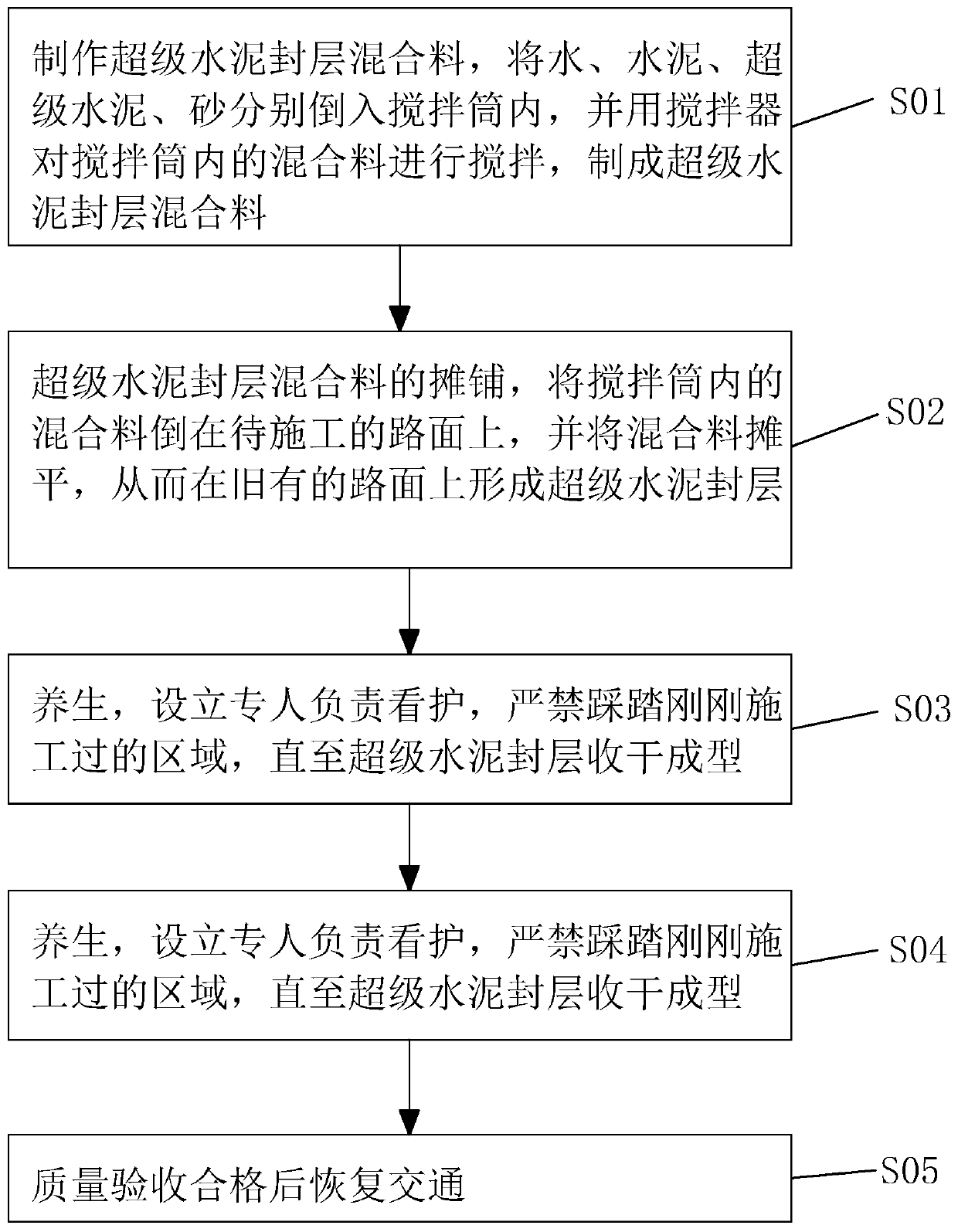

[0042] A cement concrete pavement super maintenance sealing layer construction method, the steps are as follows:

[0043] S01, first of all, it is necessary to control the traffic on the construction site, and set up conspicuous warning and prohibition signs at both ends of the specified distance from the construction site;

[0044] To clean and clean the old road surface, firstly, the dust and oil stains on the road surface are polished with a grinder, and then the road surface is cleaned with a small hair dryer and a washing machine, so that the road surface is clean and free of dirt; the porosity of the original road surface is relatively large Or when the water permeability is too high, avoid washing with water, and use high-pressure air blowing to clean;

[0045] To clean the cracks on the old pavement, first remove the sundries and dust in the cracks, and then fill the joints with a bonding material, which is a mortar made of high-content emulsified asphalt and fine sand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com