Semi-physical training system for mounting and debugging of electrical control circuits of portal cranes and bridge cranes

An electrical control system, bridge crane technology, applied in simulators, transportation and packaging, simulation devices for space navigation conditions, etc., can solve the problems of low training quality, discounted training effects, large body size, etc., and achieve the effect of skill training good, save teaching space, and take into account the effect of resource input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

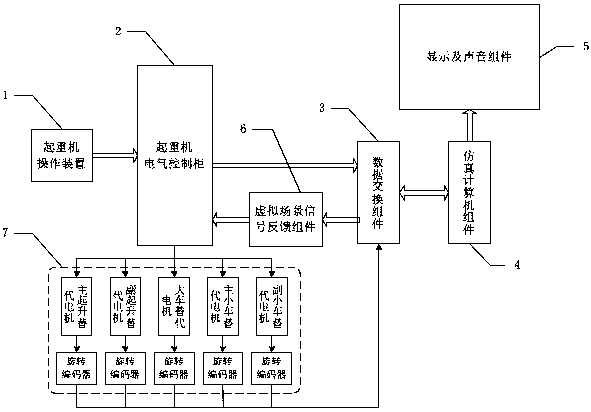

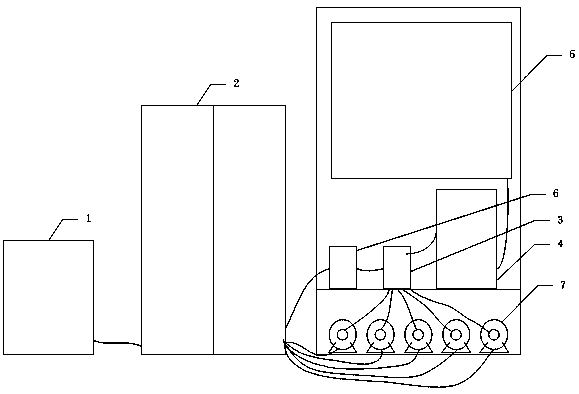

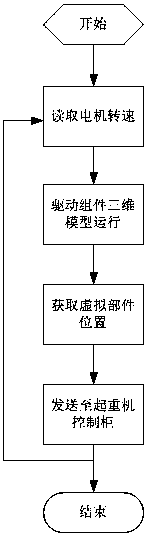

[0020] like Figure 1 to Figure 5 As shown, a semi-physical training system for the installation and adjustment of the electrical control circuit of a gantry bridge crane consists of a crane operating device 1, a crane electrical control cabinet 2 (including the crane electrical control system), a substitute motor and its rotary encoder module 7, a virtual The scene signal feedback component 6, the data exchange component 3, the simulation computer component 4, and the display and sound component 5 are composed. The signal output of the crane operating device 1 is connected to the operation signal input interface of the crane electrical control cabinet 2, and the signal input interface of the data exchange component 3 is connected to the crane The electrical control cabinet 2 is connected to the control signal output interface, the simulation c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com