Method of nonlinear friction compensation for single-motor servo system based on particle swarm algorithm

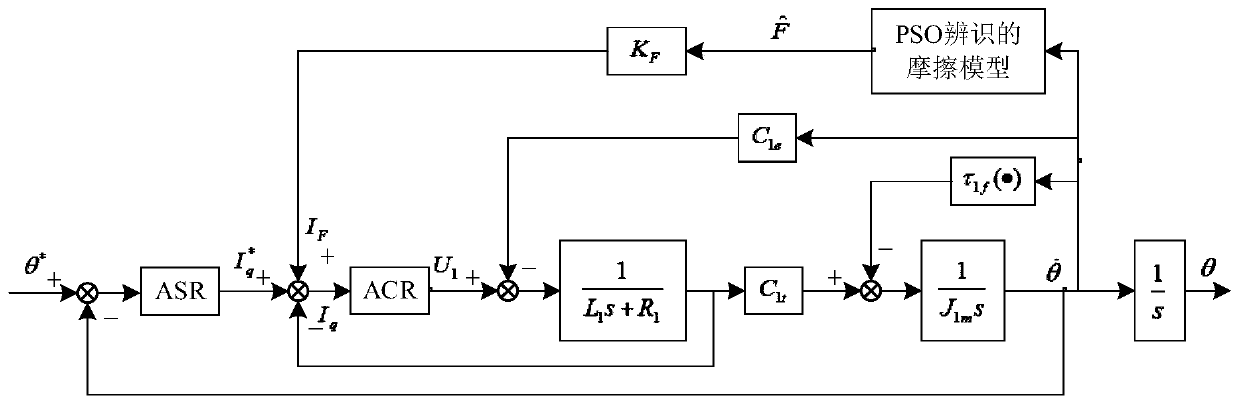

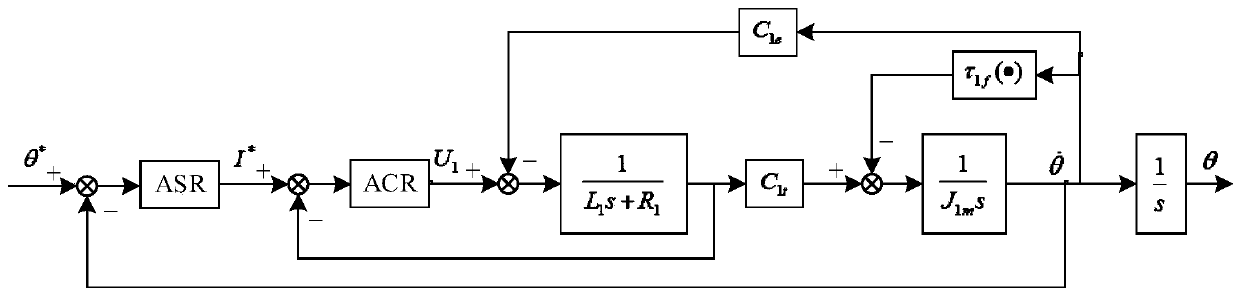

A particle swarm algorithm and nonlinear compensation technology, used in electronic commutation motor control, control systems, control generators, etc., can solve the problem of difficult to effectively estimate friction torque, difficult to achieve satisfactory results, and no description of friction torque size, etc. problem, to improve the compensation effect, solve the static tracking error, and facilitate the application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

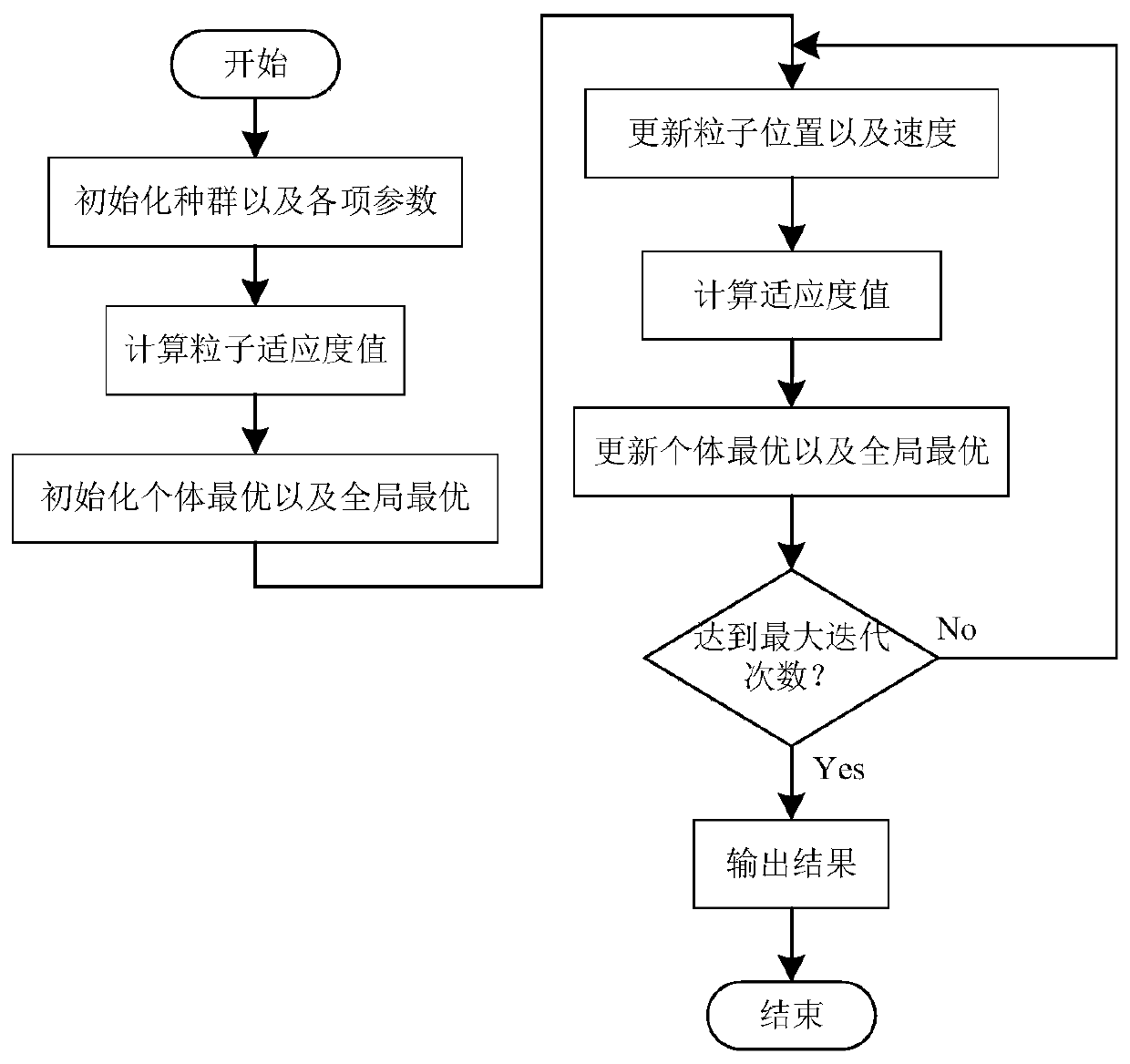

[0056] According to the Stribeck friction model of the single-motor servo system, the parameters to be identified are In the offline situation, a set of constant speed is input into the single-motor servo system as an input command. The speed controller in the system adopts a PI controller, and the input speed range is selected to be -1rad / s~1rad / s, and the sampling period is 0.03 rad / s, to obtain a set of friction torque values, such as Figure 4 shown.

[0057] The parameters of initializing the particle swarm are the particle population size n is 80; the maximum number of iterations M=500; four parameters Parameter range of motion [s 1 ,s 2 ] are (0, 1), the speed range [v 1 ,v 2 ] is [-1, 1]; learning factor c 1 =1.2,c 2 = 1.8, the results of offline identification of the Stribeck friction model by particle swarm optimization are shown in Table 1 below:

[0058] Table 1 Identification results of Stribeck friction model

[0059]

[0060] It can be seen from Ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com