Photocurable resin composition, adhesive, laminated structure, method for producing laminated structure, and display device

An adhesive and compound technology, which is applied in the directions of non-polymer organic compound adhesives, bonding methods, ester copolymer adhesives, etc. problems such as lack of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0154] The first embodiment of the photocurable resin composition according to the present embodiment is cured when exposed to light, and contains: (B) 10 to 95 parts by mass of a polyfunctional epoxy compound; and (F) 5 parts by mass to 90 parts by mass of monofunctional oxetane compounds.

[0155] The second embodiment of the photocurable resin composition according to the present embodiment, which can be employed in combination with the first embodiment, further contains (H) a polyfunctional oxetane compound. The total content of (B) polyfunctional epoxy compound and (H) polyfunctional oxetane compound is in the range of 10 to 95 parts by mass.

[0156] In the third embodiment of the photocurable resin composition according to the present embodiment that can be employed in combination with the second embodiment, the content of the (H) polyfunctional oxetane compound is in the range of 1 to 30 parts by mass Inside.

[0157] In the fourth embodiment of the photocurable resi...

Embodiment

[0273] The invention will now be described more specifically by way of illustrative examples.

[0274] 1. Embodiment (P)

[0275] (1) Preparation of adhesive

[0276] The components blended together at the blending ratio shown in Table 1 below were uniformly mixed with HOMO DISPER manufactured by PRIMIX Corporation to prepare an adhesive. Details of the components shown in Table 1 below are as follows:

[0277] (A)-1: glycidyl ether,

[0278] (A)-2: cresyl glycidyl ether,

[0279] (A)-3: 2-ethylhexyl glycidyl ether,

[0280] (B)-1: polypropylene glycol diglycidyl ether,

[0281] (B)-2: polybutadiene skeleton epoxy resin,

[0282](C): Triarylsulfonium salt,

[0283] (D)-1: lauryl acrylate,

[0284] (D)-2: 1,9-nonanediol diacrylate,

[0285] (E): 1-Hydroxy-cyclohexyl-phenyl-ketone,

[0286] (F): 3-ethyl-3{[(3-ethyloxetan-3-yl)methoxy]methyl}oxetane, and

[0287] (G): Liquid isoprene rubber.

[0288] [Table 1]

[0289]

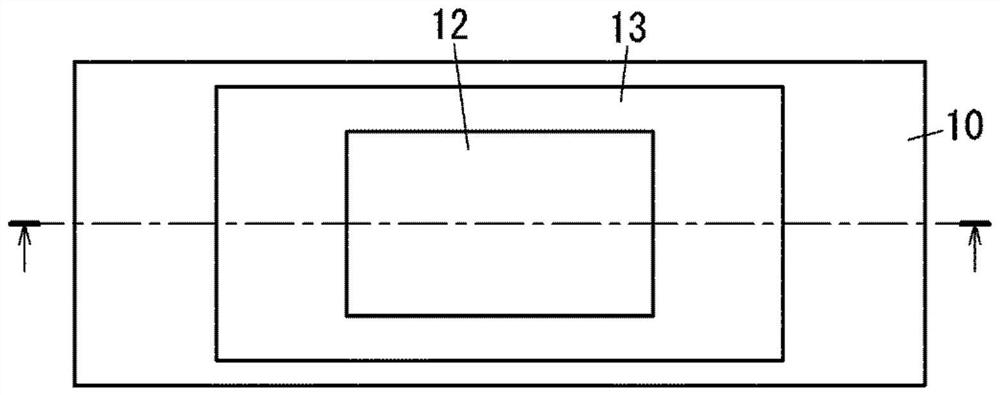

[0290] (2) Fabrication of laminated structu...

Embodiment R1

[0324] [Preparation of first adhesive and second adhesive]

[0325] The components blended together at the blending ratio (mass %) shown in the following Table 3 were uniformly mixed with DISPER to prepare the first adhesive and the second adhesive:

[0326] [table 3]

[0327]

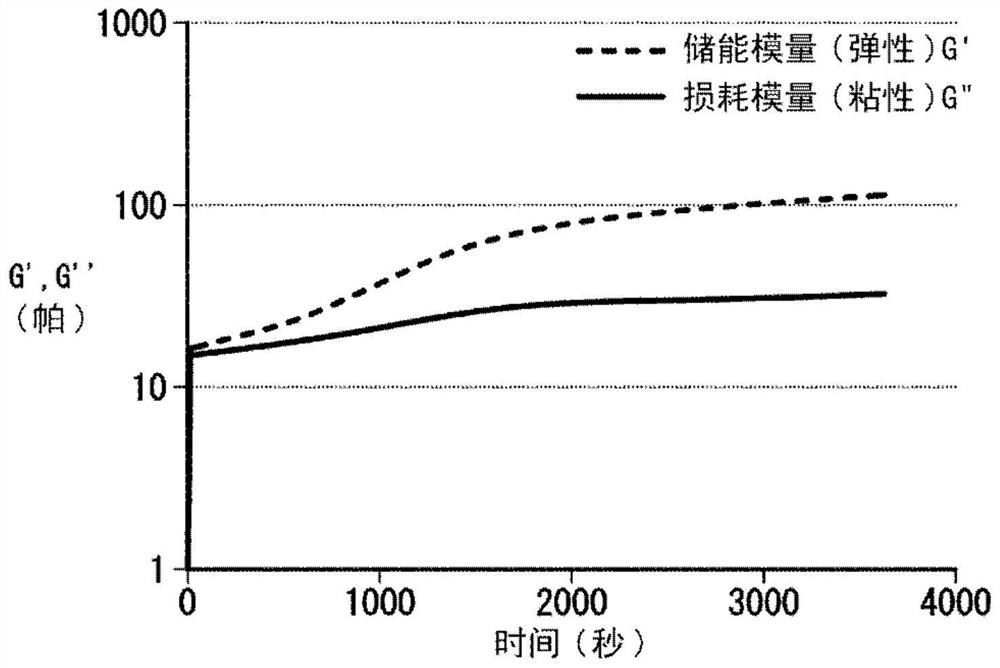

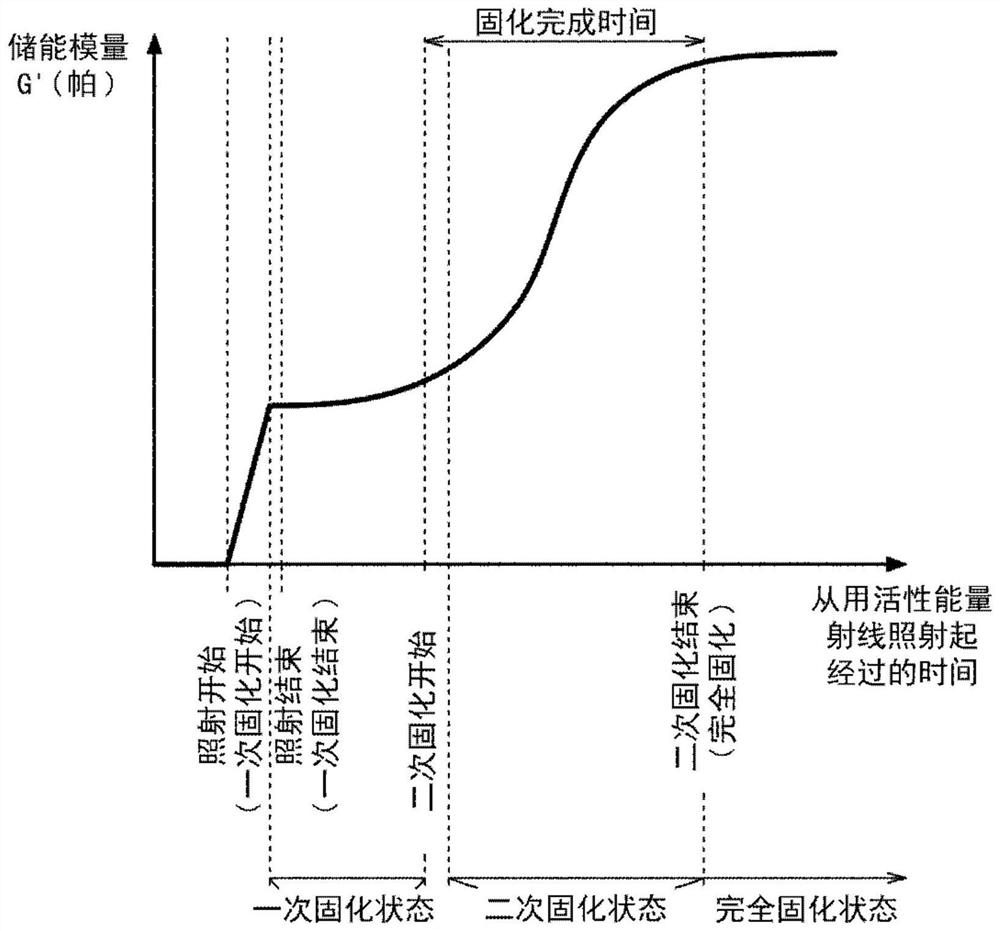

[0328] The amount of time required for the first adhesive to start curing (ie, gelation time) from immediately after the first adhesive was irradiated with ultraviolet rays (ie, gelation time) was 5 minutes. The amount of time required for the first adhesive to be completely cured from immediately after the first adhesive was irradiated with ultraviolet rays was 15 minutes. The cured product of the first adhesive (light-inhibiting portion) had a light transmittance of 3% in the visible radiation range.

[0329]The amount of time required for the second adhesive to start curing (ie, gelation time) from immediately after the second adhesive was irradiated with ultraviolet rays (ie, gelation time) wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com