Method for manufacturing surface compact internal loose ceramic core for precision casting of hollow turbine blade

A technology for ceramic cores and turbine blades, which is applied in casting molding equipment, cores, and molds, etc., can solve the problems of difficult core removal and insufficient concession of ceramic cores, and achieves improved core removal performance, low equipment requirements, Avoid cracking effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

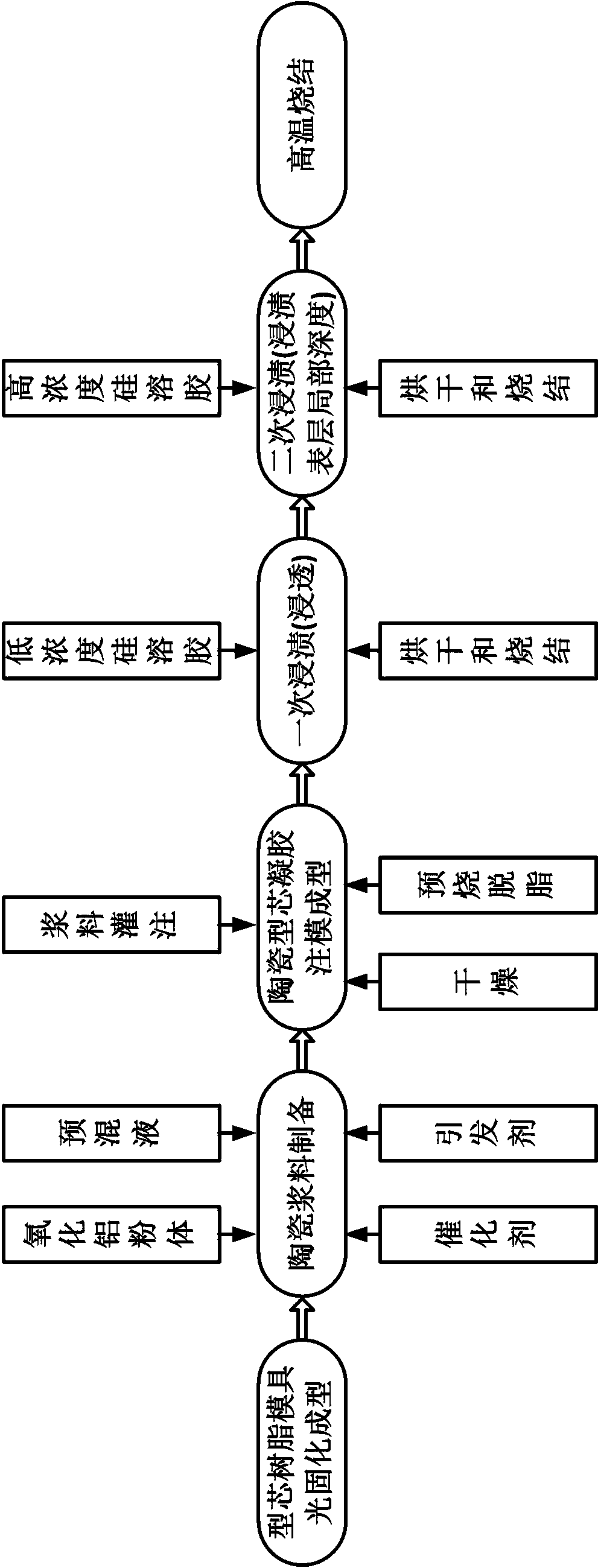

[0037] Regarding the aforementioned and other technical contents, features and effects of the present invention, refer to the appended Figure 1 to Figure 2 It will be apparent from the detailed description of the embodiments. The structural contents mentioned in the following embodiments are all based on the accompanying drawings of the description.

[0038] Exemplary embodiments of the present invention will be described below with reference to the accompanying drawings.

[0039] The present invention is a method for manufacturing an alumina-based ceramic core with a dense surface layer and a loose interior facing a hollow turbine blade, comprising the following steps:

[0040] 1) Manufacture hollow turbine blade alumina-based ceramic core resin mold.

[0041] A photocuring rapid prototyping method is adopted to prepare a ceramic core resin mold with a photosensitive resin as a raw material, and the wall thickness of the resin mold is about 0.8-1.5 mm.

[0042] 2) Ceramic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com