Precast slab for diversion canal construction

A prefabricated board and diversion channel technology, applied in the field of construction of diversion channels, can solve the problems of leakage, poor rainwater scour and flood control ability, easy to cause collapse, etc., so as to improve the ability to resist water flow impact and improve the safety of foundation pits. coefficient, the effect of reducing the possibility of piping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] For a better understanding of the present invention, the following examples are further descriptions of the present invention, but the content of the present invention is not limited to the following examples.

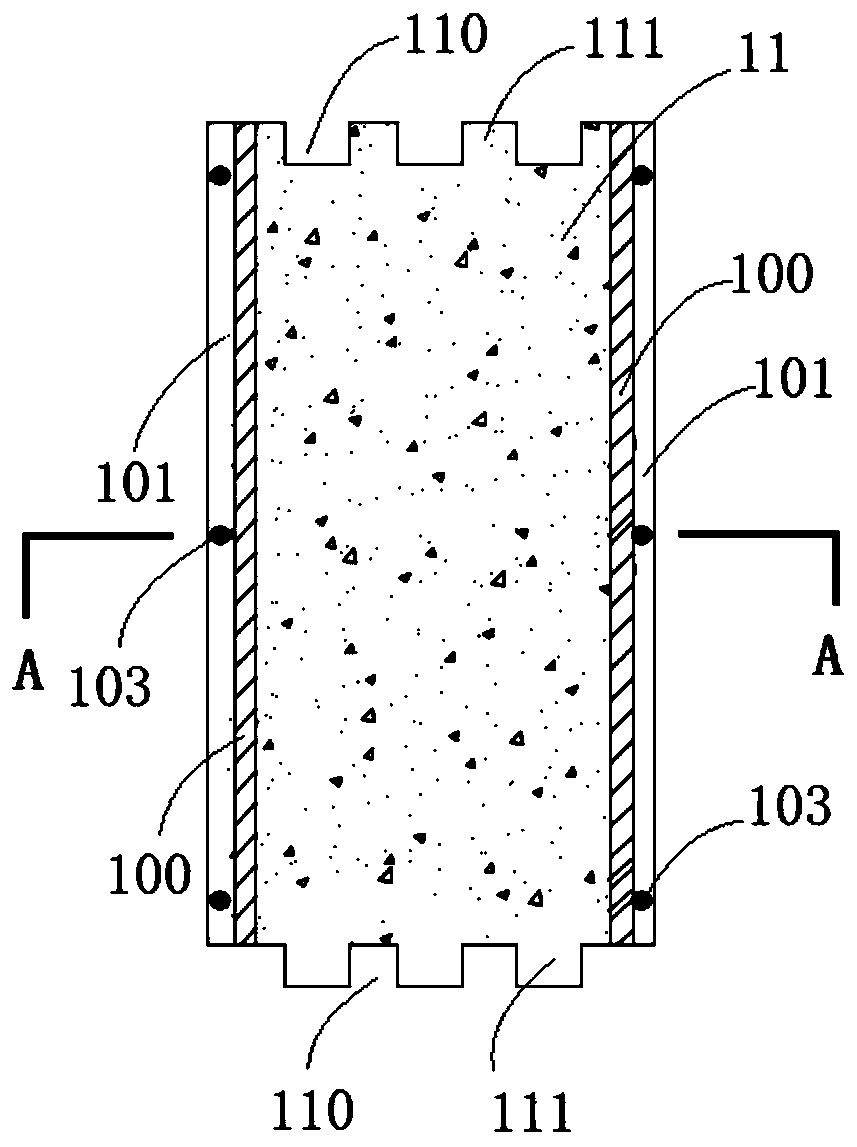

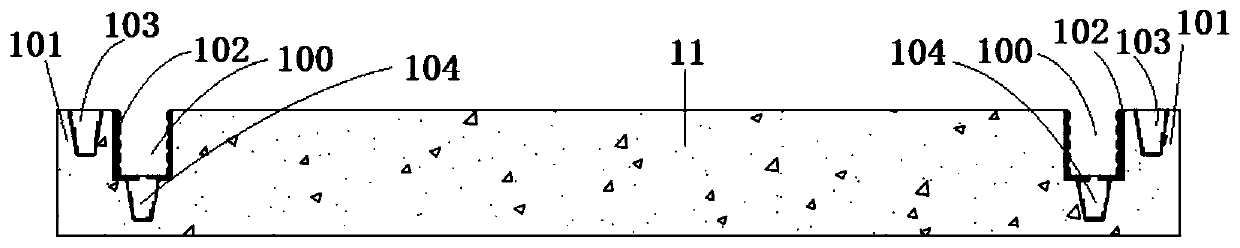

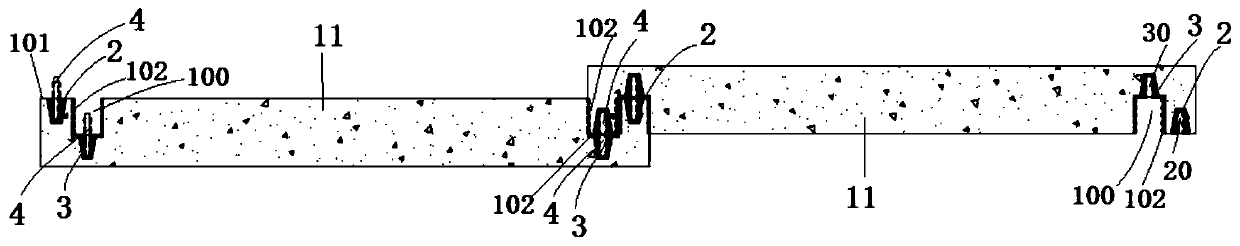

[0023] In view of the prior art, the diversion channel is generally filled with sandbags, which is likely to cause the leakage and collapse of the river water to the foundation pit, such as figure 1 , figure 2 , image 3 as well as Figure 4 As shown together, the present invention provides a prefabricated slab for diversion channel construction, including a prefabricated slab body. Both sides of the prefabricated slab body are provided with grooves 100 along the length direction of the prefabricated slab body, and a locking block 101 matching the groove 100 is formed between the groove 100 and the corresponding side surface of the prefabricated slab body. Take two prefabricated panel bodies, buckle upside down the clamping plate 101 on one side of one prefa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com