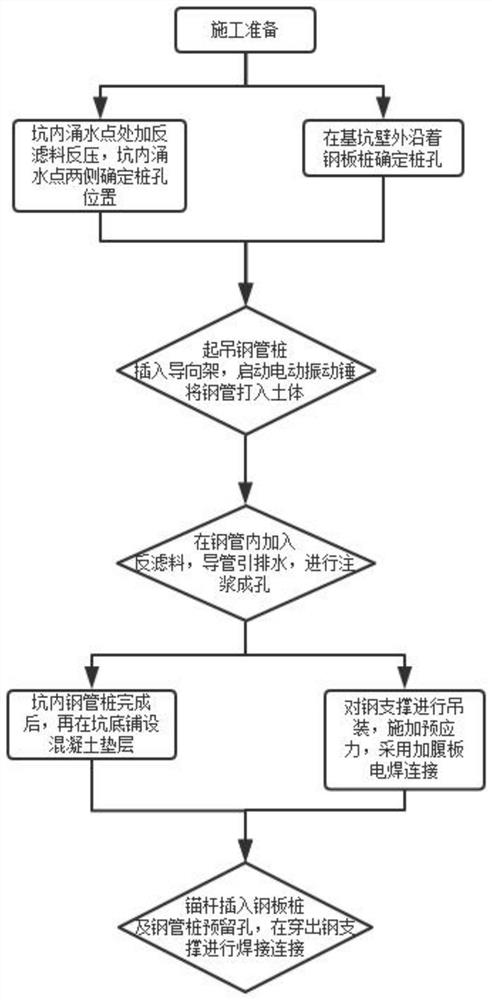

A kind of treatment method of steel sheet pile supporting foundation pit piping

A technology for steel sheet piles and foundation pits, which is applied in the direction of sheet pile walls, excavation, protection devices, etc., can solve the problems of water pile collapse holes and increase construction difficulty, and achieve the effects of safe use, hole collapse prevention, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

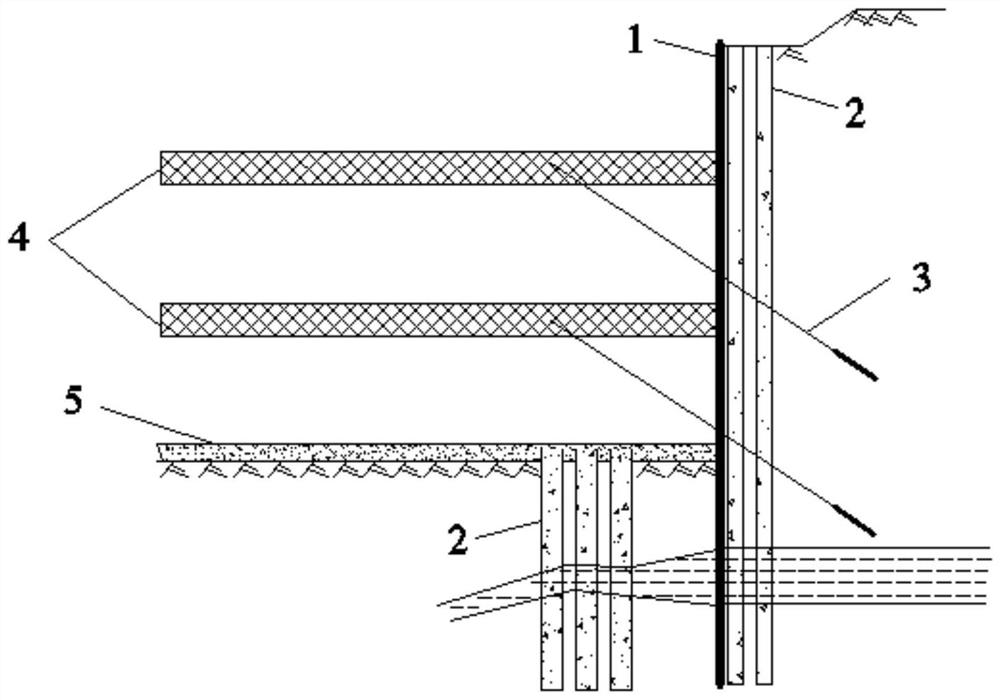

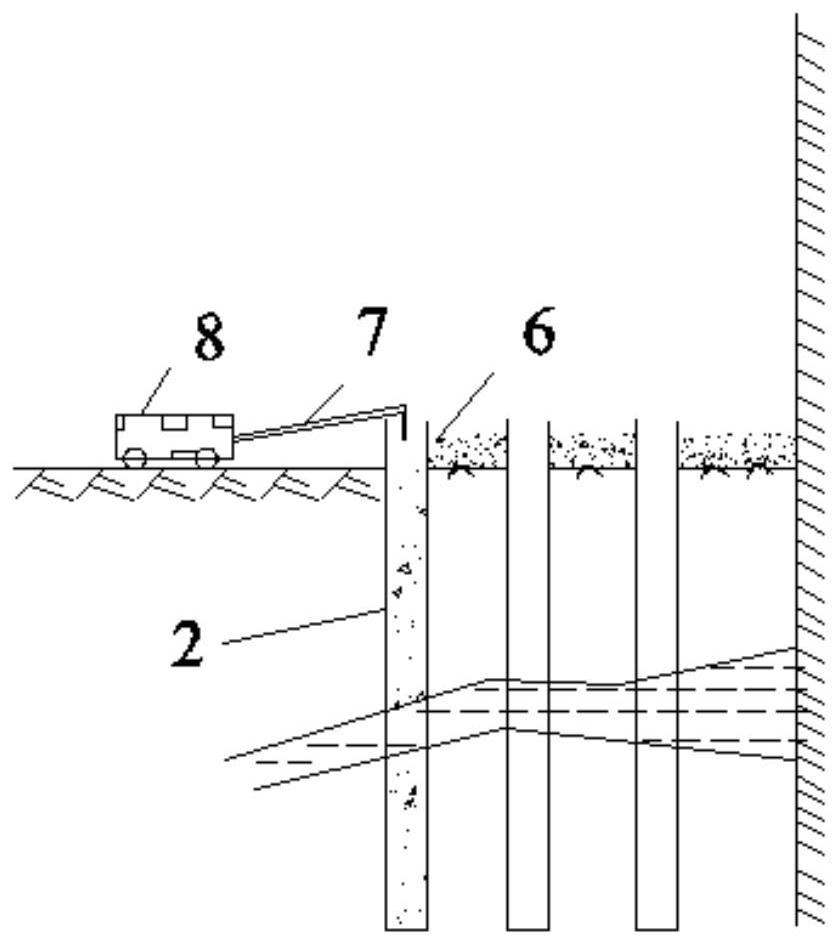

[0023] In order to more clearly understand the above objects, features and advantages of the present invention, the present invention will be further described below with reference to the accompanying drawings and embodiments. Numerous specific details are set forth in the following description to facilitate a full understanding of the present invention, however, the present invention may also be practiced in other ways than those described herein, and therefore, the present invention is not limited to the specific embodiments disclosed below.

[0024] like Figure 2-3 As shown in the figure, the construction components involved in the management method of the steel sheet pile supporting foundation pit piping proposed in this embodiment include steel sheet pile 1, steel pipe pile 2, anchor rod 3, steel support 4, concrete cushion 5, anti-filter material 6. Grouting pipe 7 and grouting truck 8. During construction, the steel pipe pile 2 and the steel sheet pile 1 keep the same ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com