Method for reinforcing foundation pit enclosure

A foundation pit enclosure and foundation pit technology, which is applied in excavation, foundation structure engineering, sheet pile walls, etc., can solve problems such as unsatisfactory use effect, difficult excavation of foundation pits, and limited mixing degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

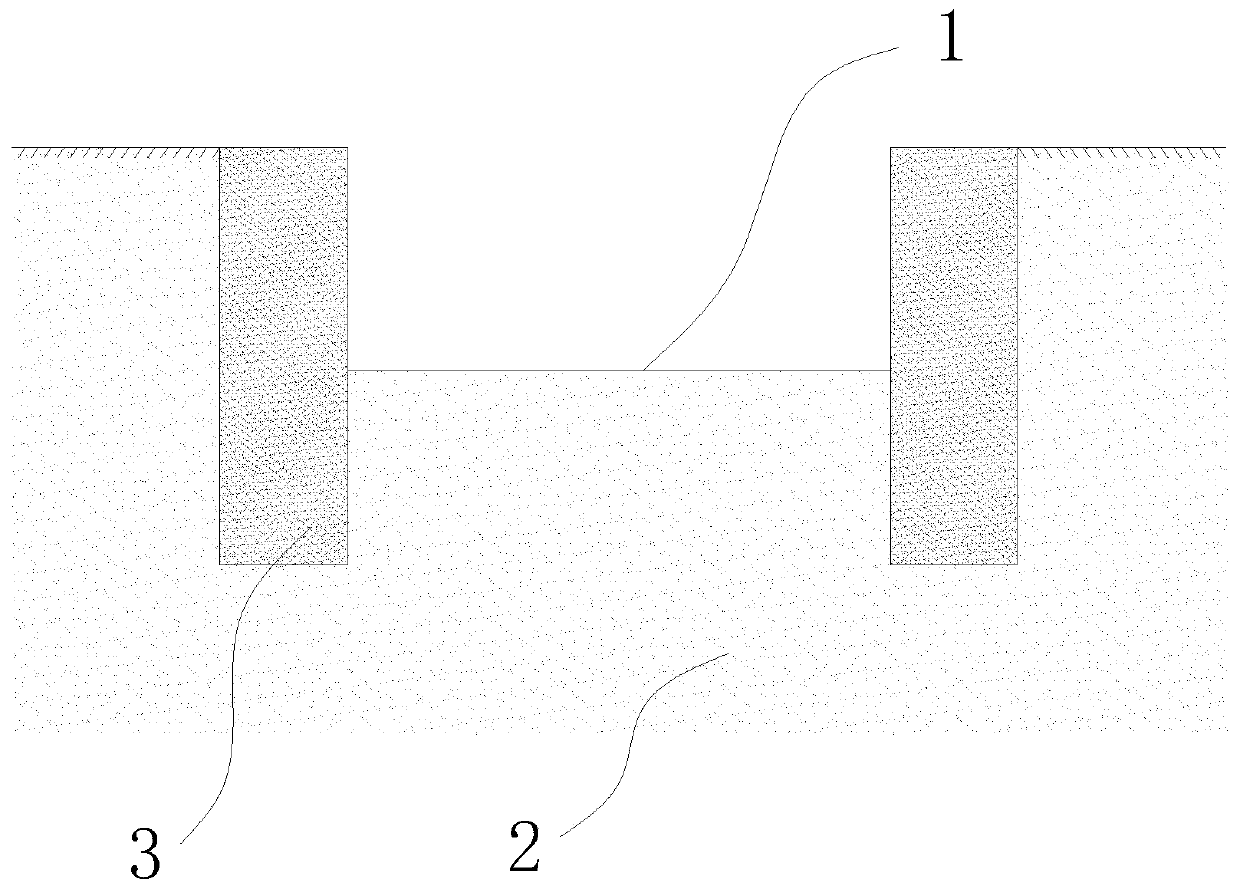

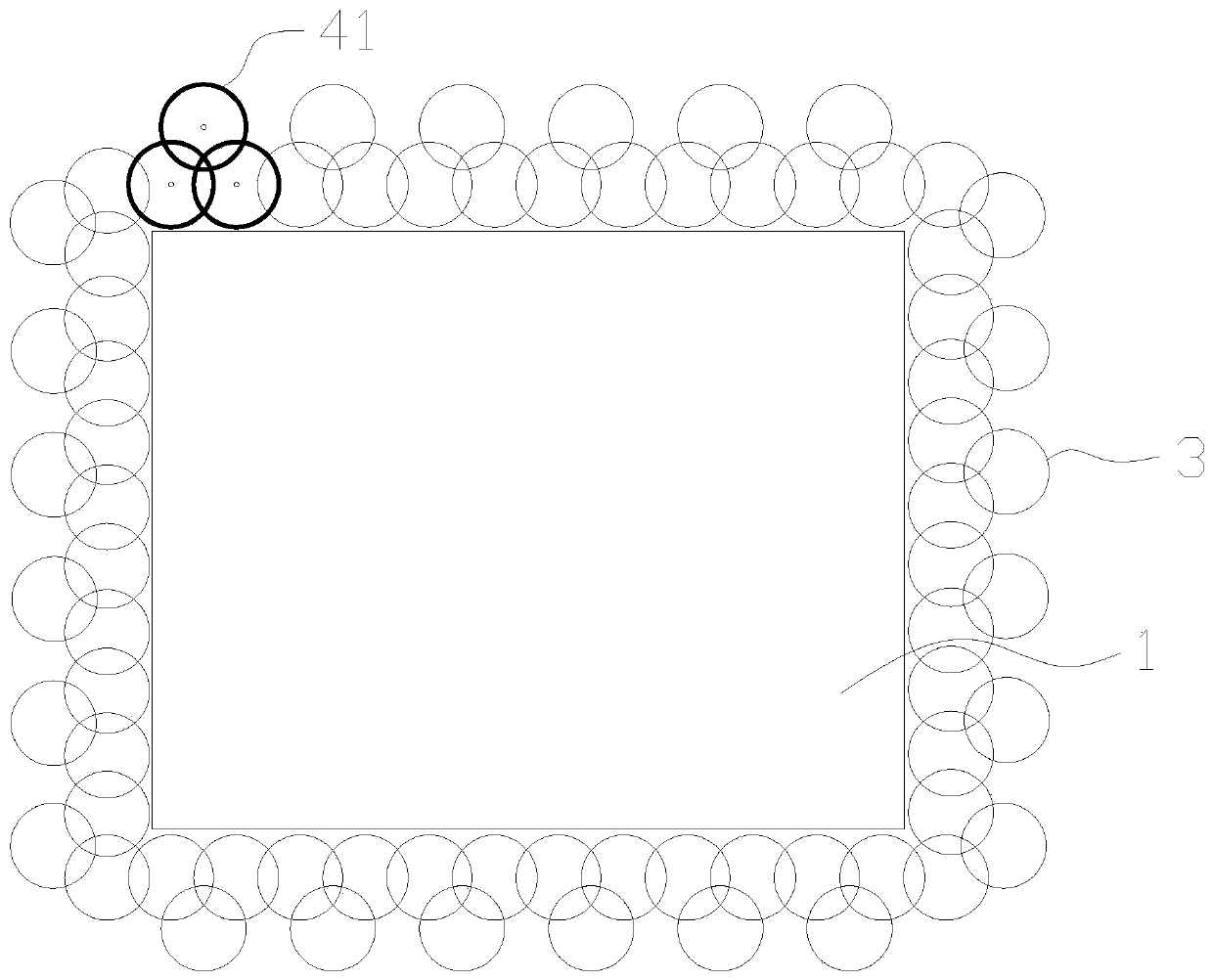

[0037] The foundation pit enclosure strengthening method provided in this embodiment is to set a plurality of first polygonal soil reinforcement blocks 41 down to the depth of the foundation pit on the weak bearing layer 2 at the edge of the foundation pit 1 and adjoin them to form a stop. A foundation pit edge reinforcement structure 3 with strong water, soil retaining, and bending resistance, wherein the first polygonal soil reinforcement block 41 is drilled into three or more phases by the first multi-axis combination drill arranged in a non-linear manner with more than three axes. Adjacent to the first circular soil reinforcement block, every three adjacent drill rods are distributed in a triangle and the construction areas of the three drill rods are partially overlapped.

[0038] In the foundation pit enclosure strengthening method of this embodiment, the multi-axis rotary spraying drill is used as the first multi-axis combined drill to form the first multi-curved edge by...

Embodiment 2

[0054] The same parts as those in Embodiment 1 are given the same reference numerals, and the same text descriptions are omitted.

[0055] Compared with Example 1, the foundation pit enclosure strengthening method provided in this example uses a multi-axis mechanical agitation drill as the first multi-axis combination drill, and uses the cement mixing method to uniformly mix and spray the weak bearing layer 2 at the edge of the foundation pit 1. The agent forms the first polygonal soil reinforcement block 41 to strengthen the soil. The first multi-curved soil reinforcement block 41 is formed by non-linearly arranged multi-axis mixing drills arranged in sequence along the circumference of the foundation pit 1 and drilled down and sprayed with a curing agent. The strengthening method of the foundation pit enclosure in this embodiment mainly consists in setting the reinforcement structure at the edge of the foundation pit, and the specific strengthening method includes the follow...

Embodiment 3

[0063] The same parts as those in Embodiment 1 are given the same reference numerals, and the same text descriptions are omitted.

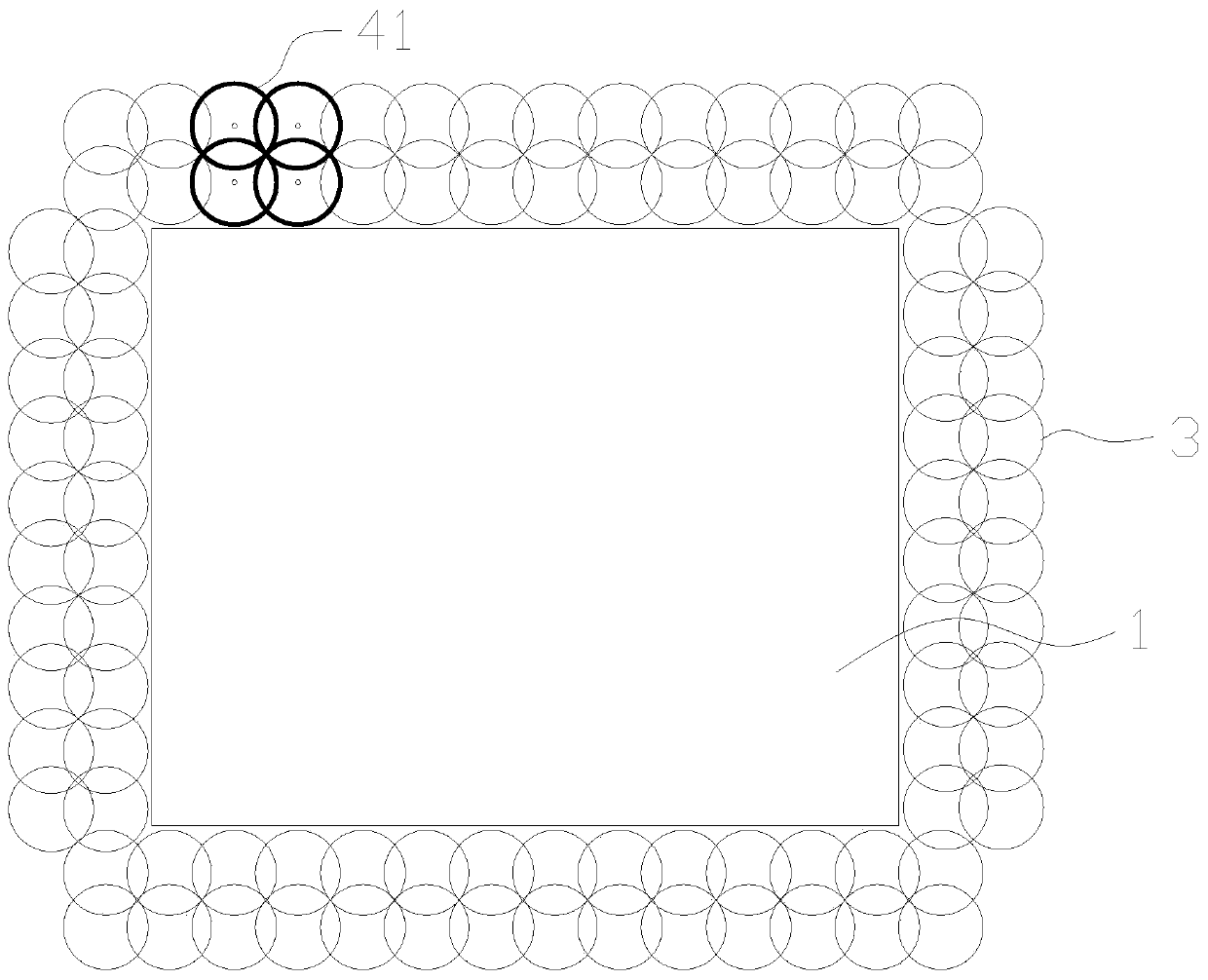

[0064] Compared with Example 1, the foundation pit enclosure strengthening method provided by this embodiment uses a multi-axis rotary jet drill as the first multi-axis combined drill, and uses a high-pressure rotary jet drilling method to break the soil of the weak bearing layer 2 at the edge of the foundation pit 1 And mix the curing agent to form the first polygonal soil reinforcement block 41 to strengthen the soil. The first polygonal soil reinforcement block 41 is formed by non-linearly arranged three-axis rotary jet drills arranged in sequence along the circumference of the foundation pit 1 and then sprayed with a curing agent.

[0065] Such as Figure 5 As shown, a plurality of first polygonal soil reinforcement blocks 41 are arranged along the circumference of the foundation pit 1, wherein at least two first polygonal soil reinforcement ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com