Chinese-style flue-cured tobacco flavor type solid particles for electronic cigarettes and preparation method of Chinese-style flue-cured tobacco flavor type solid particles

A technology of solid particles and electronic cigarettes, which is applied in the field of electronic cigarettes, can solve the problems of aroma and taste that cannot meet the standard, cannot extract the original taste of tobacco leaves, and discount the desire for Chinese cigarettes, so as to retain the original taste, reliable original taste, The effect of enriching the taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

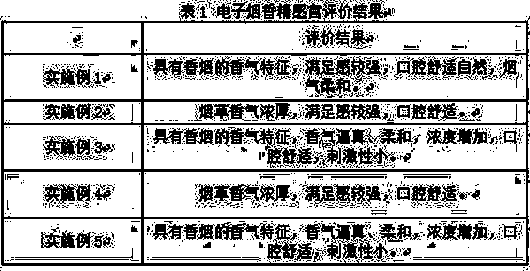

Examples

Embodiment 1

[0034] S1. Tobacco leaf pretreatment: the tobacco leaves are firstly fermented, aged, and re-fermented, and then dried and pulverized to obtain tobacco leaf powder;

[0035] S2. Add 10 parts of sodium methylcellulose and 10 parts of microcrystalline cellulose to 50 parts of tobacco leaf powder, and mix uniformly to obtain a blend;

[0036] S3. Add 10 parts of glycerin, 5 parts of propylene glycol, 9 parts of deionized water, 0.8 parts of tobacco-flavored essence, and 0.2 parts of roasted essence to the blend, and stir and mix evenly to obtain a soft material;

[0037] S4. After the soft materials are granulated, they are then dried at a drying temperature of 75° C. and a drying time of 8 minutes to obtain Chinese-style flue-cured tobacco flavor solid particles for electronic cigarettes.

Embodiment 2

[0039] S1. Tobacco leaf pretreatment: the tobacco leaves are firstly fermented, aged, and re-fermented, and then dried and pulverized to obtain tobacco leaf powder;

[0040] S2. Add 10 parts of microcrystalline cellulose and 4 parts of modified starch to 60 parts of tobacco leaf powder, and mix evenly to obtain a blend;

[0041] S3. Add 20 parts of glycerin, 5 parts of deionized water, 0.8 parts of tobacco-flavored essence, and 0.2 parts of roasted essence to the blend, and stir and mix evenly to obtain a soft material;

[0042] S4. After the soft materials are granulated, they are then dried at a drying temperature of 80° C. and a drying time of 10 minutes to obtain Chinese-style flue-cured tobacco flavor solid particles for electronic cigarettes.

Embodiment 3

[0044] S1. Tobacco leaf pretreatment: the tobacco leaves are firstly fermented, aged, and re-fermented, and then dried and pulverized to obtain tobacco leaf powder;

[0045] S2. Add 5 parts of microcrystalline cellulose, 5 parts of modified starch and 5 parts of sodium carboxymethyl cellulose to 55 parts of tobacco leaf powder, and mix uniformly to obtain a blend;

[0046] S3. Add 15 parts of glycerin, 9 parts of deionized water, 0.8 part of roasted flavor essence, 0.2 part of fruity flavor essence to the blend, stir and mix evenly to obtain soft material;

[0047] S4. After the soft material is granulated, it is then dried at a drying temperature of 95° C. and a drying time of 12 minutes to obtain Chinese-style flue-cured tobacco flavor solid particles for electronic cigarettes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com