Preparation method and application of composite nicotine salt and electronic tobacco tar

A technology of nicotine salt and linoleic acid, applied in the field of electronic cigarettes, can solve the problems of fragrance, the effect of relieving smoking addiction, and the safety of use is not ideal, and achieve the effect of excellent smoking experience, close fragrance, and relieving smoking addiction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

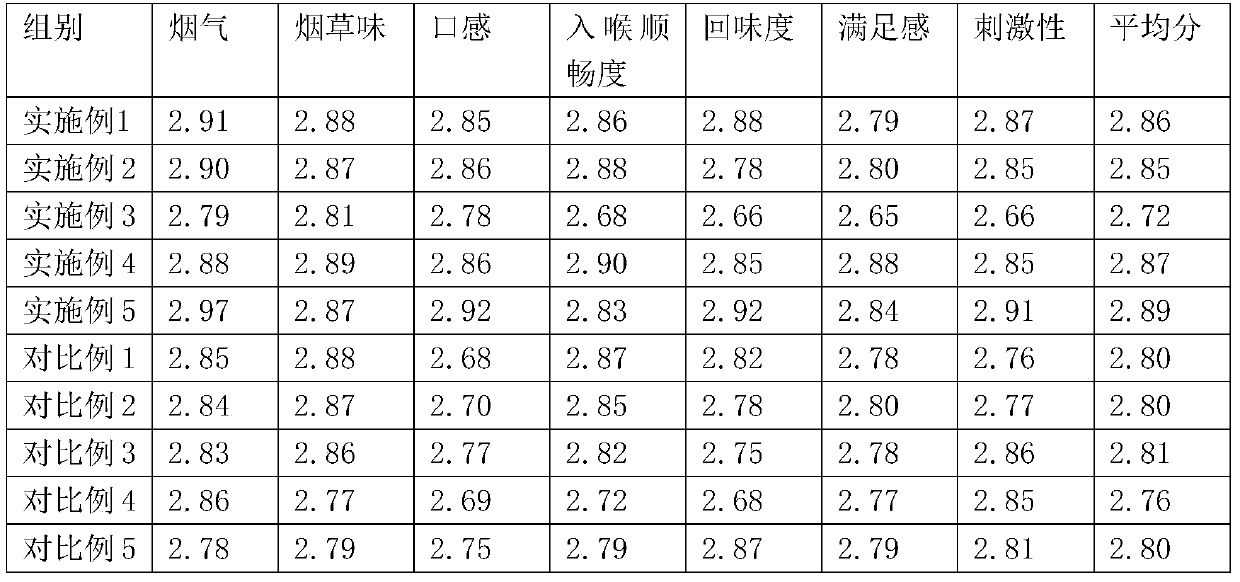

Examples

Embodiment 1

[0019] This embodiment provides a compound nicotine salt. The raw material components include: 500g of organic acid and 500g of nicotine base. %, citric acid 9%, malic acid 10%, ascorbic acid 1%.

[0020] Further, a method for preparing the compound nicotine salt is provided, comprising the steps of: mixing 100 g of benzoic acid, 50 g of linolenic acid, 250 g of linoleic acid, 45 g of citric acid, 50 g of malic acid, and 5 g of ascorbic acid according to the above mass ratio to obtain a mixed Material S1; mix 250g squalene and 250g squalane uniformly at 1:1 to obtain mixture S2; pour mixture S2 into mixture S1, then add 500g of nicotine base, 250g of glycerol and propylene glycol, and heat Heat to 50°C, stir while heating to fully react, the speed of stirring is 50rpm, that is to say.

Embodiment 2

[0022] This embodiment provides a compound nicotine salt. The raw material components include: 400g of organic acid and 600g of nicotine base. %, citric acid 9%, malic acid 10%, ascorbic acid 1%.

[0023] Further, a method for preparing the compound nicotine salt is provided, comprising the steps of: mixing 80 g of benzoic acid, 40 g of linolenic acid, 200 g of linoleic acid, 36 g of citric acid, 40 g of malic acid, and 4 g of ascorbic acid according to the above mass ratio to obtain a mixed Material S1; mix 250g squalene and 250g squalane uniformly at 1:1 to obtain mixture S2; pour mixture S2 into mixture S1, then add 600g of nicotine base, 250g of glycerol and propylene glycol, and heat Heat to 50°C, stir while heating to fully react, the speed of stirring is 50rpm, that is to say.

Embodiment 3

[0025] This embodiment provides a compound nicotine salt, the raw material components include: 600g of organic acid, 400g of nicotine base, the organic acid is composed of the following components in mass percentage: 20% of benzoic acid, 10% of linolenic acid, 50% of linoleic acid %, citric acid 9%, malic acid 10%, ascorbic acid 1%.

[0026] Further, a method for preparing the compound nicotine salt is provided, comprising the steps of: mixing 120 g of benzoic acid, 60 g of linolenic acid, 600 g of linoleic acid, 54 g of citric acid, 60 g of malic acid, and 6 g of ascorbic acid according to the above mass ratio to obtain a mixed Material S1; mix 250g squalene and 250g squalane uniformly at 1:1 to obtain mixture S2; pour mixture S2 into mixture S1, then add 400g of nicotine base, 250g of glycerol and propylene glycol, and heat Heat to 50°C, stir while heating to fully react, the speed of stirring is 50rpm, that is to say.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com