Mold storage limiter

A stopper and mold technology, applied in the field of stamping molds, can solve the problems of large mold volume, loss of kinetic energy of machine tool tonnage, and increased cost of nitrogen cylinder storage, and achieve the goal of reducing manual operation, reducing kinetic energy loss, and reducing force source Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing, the present invention will be further described:

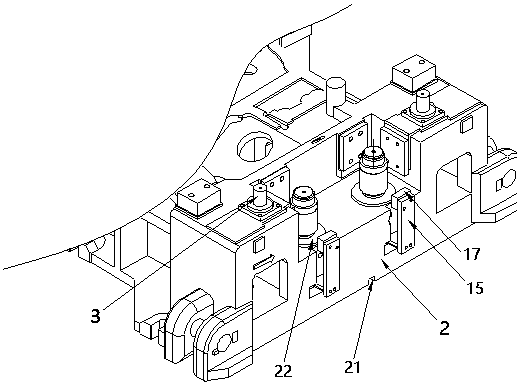

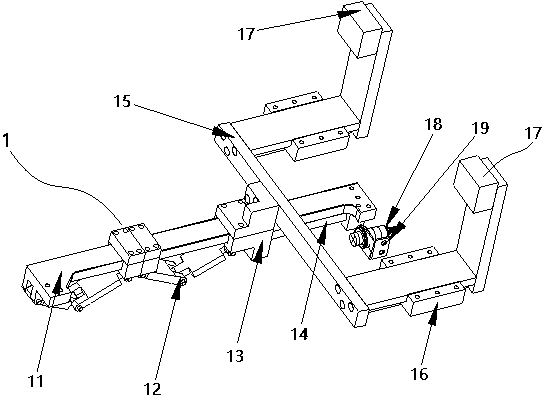

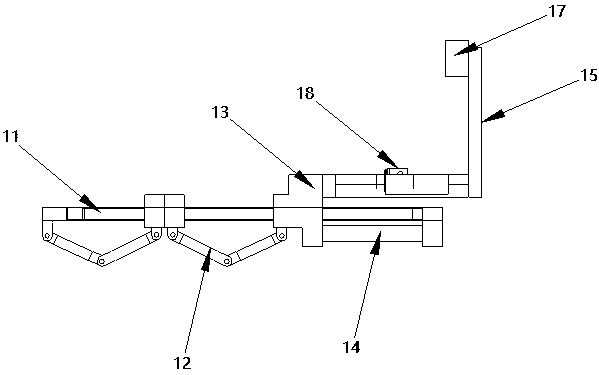

[0031] Figure 1 to Figure 8 A specific implementation manner of a mold storage limiter of the present invention is shown.

[0032] Such as Figure 1 to Figure 8 As shown, the mold storage limiter in this embodiment includes a rigid limiter 1 and an elastic limiter 3 arranged on the lower mold base 2, and the rigid limiter 1 and the elastic limiter 3 are used in combination; the rigid limiter The positioner 1 comprises a guide rod 11, a slide block 13 and a limit block 17, the two ends of the guide rod 11 are installed on the lower mold base 2, the slide block 13 is slidably arranged on the guide rod 11, one end of the guide rod 11 and A multi-link mechanism 12 is arranged between one end of the slider 13 to push the slider 13 to slide along the guide rod 11, and a return spring 14 is arranged between the other end of the slider 13 and the lower mold base 2; 15 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com