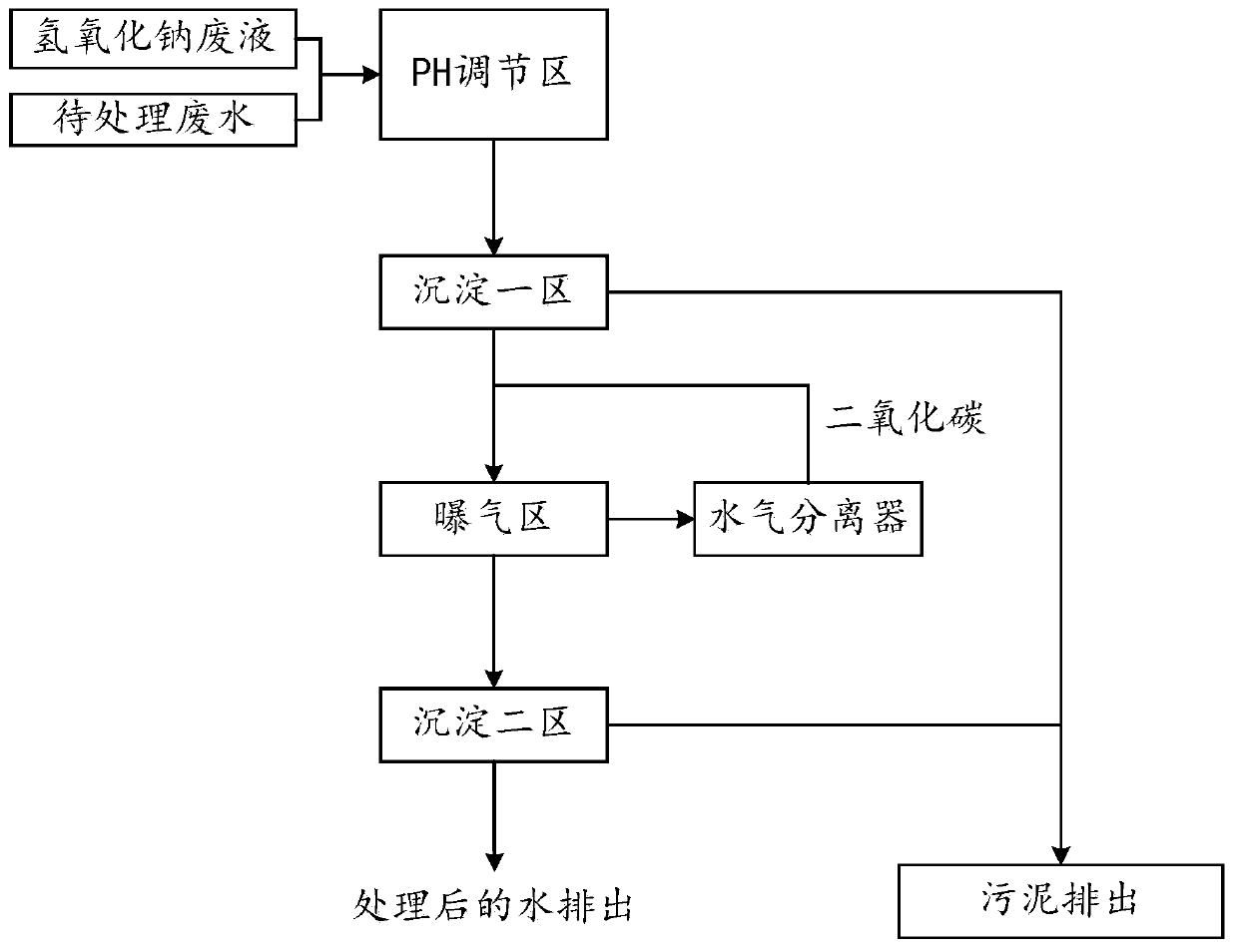

Integrated wastewater hardness removal device and treatment method

An all-in-one, wastewater technology, applied in water treatment parameter control, neutralized water/sewage treatment, water/sewage multi-stage treatment, etc., to achieve the effect of reducing procurement costs, simple operation procedures, and lowering operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

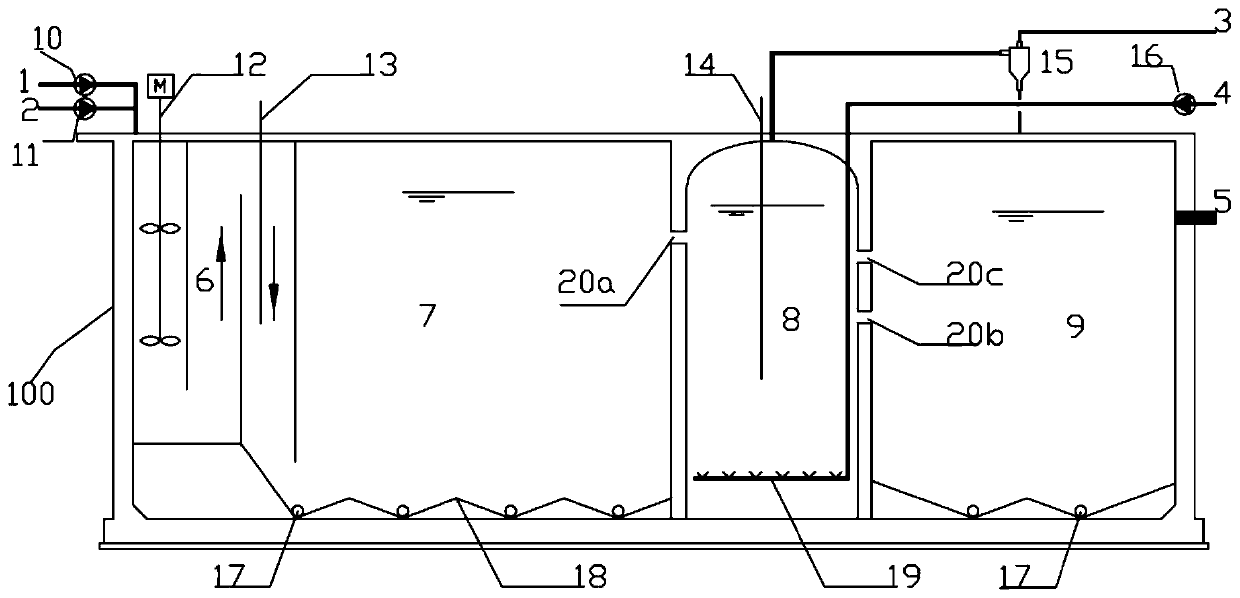

[0041] Various exemplary embodiments, features, and aspects of the invention will be described in detail below with reference to the accompanying drawings. The same reference numbers in the figures indicate functionally identical or similar elements. While various aspects of the embodiments are shown in drawings, the drawings are not necessarily drawn to scale unless specifically indicated.

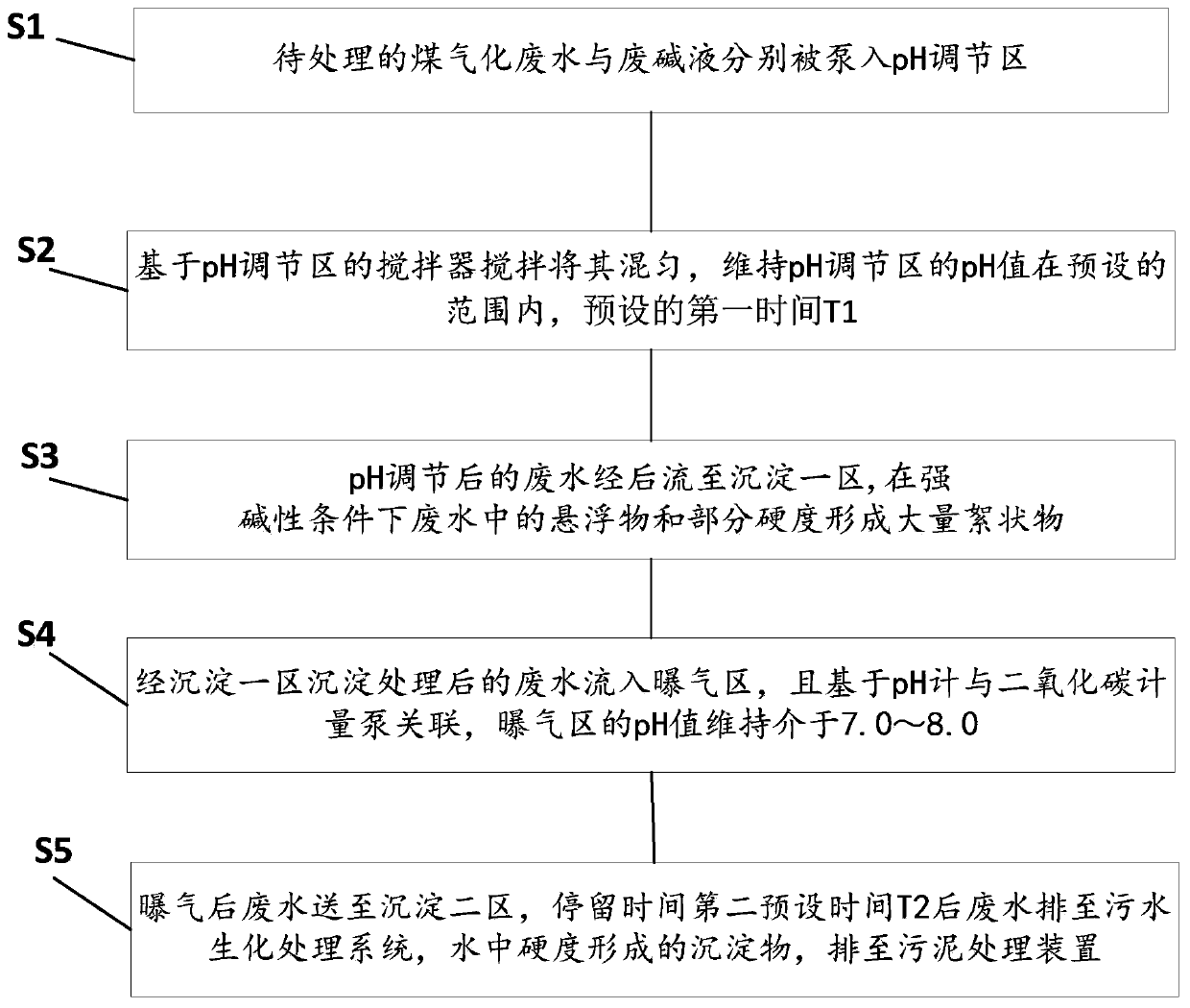

[0042] The embodiment of the present application provides an integrated waste water dehardening device (used for coal gasification), and the treatment process (method) of the treatment device is simple. It is mainly suitable for the treatment of high hardness wastewater in coal chemical industry and other industries. The device includes: a device body, which is equipped with a pH adjustment area, a precipitation area 1, an aeration area, a precipitation area 2, and a control module; wherein, the pH adjustment area and the aeration area are respectively equipped with a pH meter; the devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com