Preparation method of modified plastic particles containing waste polyurethane

A technology of plastic granules and polyurethane, which is applied in the field of preparation of modified plastic granules, can solve the problems of low competitiveness in effect and life, poor quality of mechanical properties, etc., and achieve reasonable reuse, good surface activity, and good practical value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

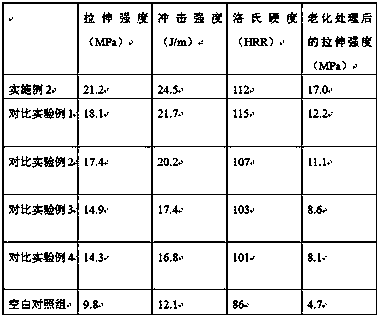

Examples

Embodiment 1

[0027] A preparation method of modified plastic particles containing waste polyurethane, comprising the steps of:

[0028] (1) First put the carbon nanotubes into the phosphoric acid solution, keep stirring for 4 minutes, then filter out, rinse with deionized water and then put them into the silane coupling agent, filter out after ultrasonic treatment for 20 minutes, and finally put them into After drying in the drying box for 10 minutes, it is ready for use;

[0029] (2) Put the carbon nanotubes treated in step (1) into the ethanol solution, ultrasonically disperse evenly, then drop in tetraethyl orthosilicate at a rate of 3ml / min, and keep stirring until uniform to obtain the mixed solution A for later use;

[0030] (3) Add ammonia solution dropwise to the mixture A prepared in step (2) at a rate of 1ml / min, continuously stir and react for 3 hours, then carry out centrifugal filtration, then wash and dry the centrifuged solids to obtain mixture B for later use ;

[0031] (...

Embodiment 2

[0043] A preparation method of modified plastic particles containing waste polyurethane, comprising the steps of:

[0044] (1) First put the carbon nanotubes into the phosphoric acid solution, keep stirring for 5 minutes, then filter out, wash it with deionized water, put it into the silane coupling agent, and filter it out after ultrasonic treatment for 23 minutes, and finally put it into After drying in the drying box for 12 minutes, it is ready for use;

[0045] (2) Put the carbon nanotubes treated in step (1) into the ethanol solution, ultrasonically disperse evenly, then drop in tetraethyl orthosilicate at a rate of 3.5ml / min, and stir continuously until it is uniform to obtain the mixed solution A for later use ;

[0046] (3) Add ammonia solution dropwise to the mixture A prepared in step (2) at a rate of 1.3ml / min, continuously stir and react for 3.6h, then carry out centrifugal filtration, then wash and dry the centrifuged solids to obtain the mixture B standby;

[...

Embodiment 3

[0059] A preparation method of modified plastic particles containing waste polyurethane, comprising the steps of:

[0060] (1) First put the carbon nanotubes into the phosphoric acid solution, keep stirring for 6 minutes, then filter out, rinse with deionized water, put them into the silane coupling agent, filter out after ultrasonic treatment for 25 minutes, and finally put them into After drying in the drying box for 15 minutes, it is ready for use;

[0061] (2) Put the carbon nanotubes treated in step (1) into the ethanol solution, ultrasonically disperse evenly, then drop in tetraethyl orthosilicate at a rate of 4ml / min, and keep stirring until uniform to obtain the mixed solution A for later use;

[0062] (3) Drop ammonia solution into the mixture A prepared in step (2) at a rate of 1.5ml / min, continuously stir and react for 4 hours, then perform centrifugal filtration, then wash and dry the centrifuged solids to obtain mixture B spare;

[0063] (4) Weigh the following ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com