Method and device for producing pellet ores

A technology of pelletizing and belt roasting machine, which is applied in the field of iron ore pellet production, and can solve problems such as the decline in the quality of pellets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

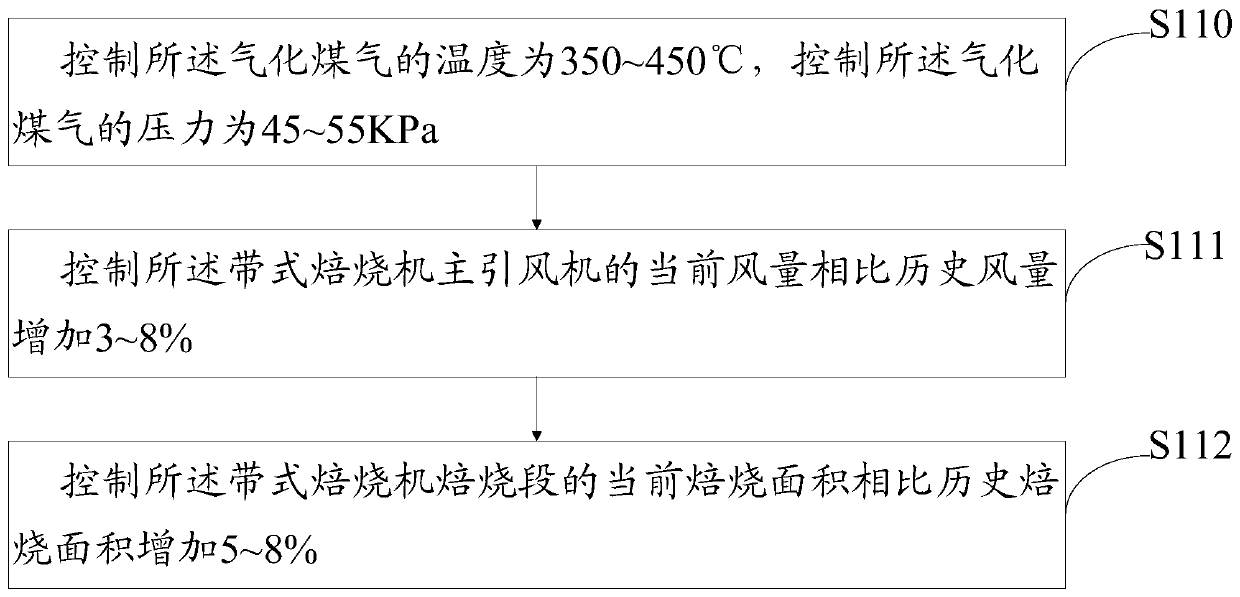

[0029] This embodiment provides a method for generating pellets, which is applied in a belt roaster, and the method includes:

[0030] S110, controlling the temperature of the gasification gas to be 350-450°C, and controlling the pressure of the gasification gas to be 45-55KPa;

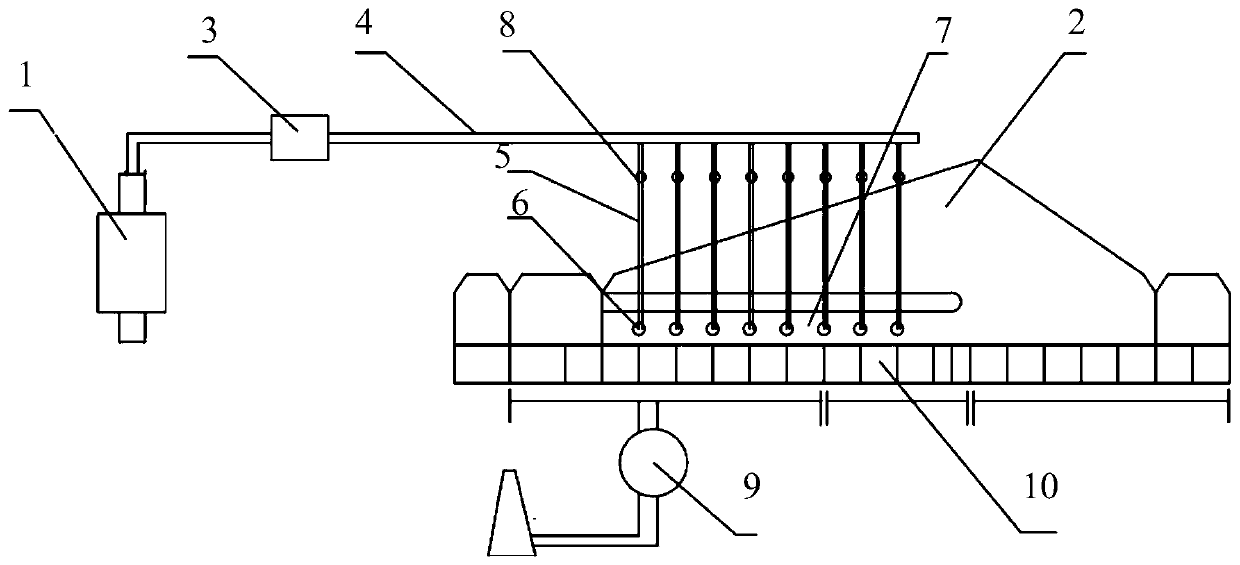

[0031] here, see figure 2 , The gasifier 1 is connected to the belt roaster 2, and firstly based on coal, oxygen and water vapor, the gasifier 1 is used to react to generate gasified coal gas. The outlet temperature of the gasification gas is controlled at 350-450° C., and the pressure of the gasification gas is controlled at 45-55 KPa through the pressure regulator 3 .

[0032] The gasification gas is transported to the gas branch pipe 5 of the belt roaster 2 through the high temperature pipeline 4, the gasification gas enters the burner 6 of the belt roaster through the gas branch pipe 5, and the gasification gas is the combustion chamber 7 of the belt roaster Provides heat flow. Here, the flow ...

Embodiment 2

[0042] This embodiment provides a device for generating pellets, such as image 3 As shown, the device includes: a generation unit 31, a first control unit 32, a second control unit 33 and a third control unit 34; wherein,

[0043] see figure 2 , the gasifier 1 is connected to the belt roaster 2, and the generation unit 31 first uses the coal gasifier 1 to react to generate gasified coal gas based on coal, oxygen and water vapor. The first control unit 32 is used to control the outlet temperature of the gasification gas to 350-450° C., and to control the pressure of the gasification gas to 45-55 KPa through the pressure regulator 3 .

[0044] Then the gasification gas is transported to the gas branch pipe 5 of the belt roaster 2 through the high temperature pipeline 4, and the gasification gas enters the burner 6 of the belt roaster through the gas branch pipe 5, and the gasification gas is the combustion chamber of the belt roaster 7 to provide heat flow. Here, the flow r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com