Desulfurization ash treatment method

A treatment method and desulfurization ash technology, which are applied in the field of desulfurization ash treatment, can solve the problems of polluting the environment, difficult to treat and recycle desulfurization ash, and occupying land for desulfurization ash, so as to reduce energy consumption, improve quality indicators and improve the metallurgical performance of sintered ore. , the effect of improving the fluidity of the liquid phase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

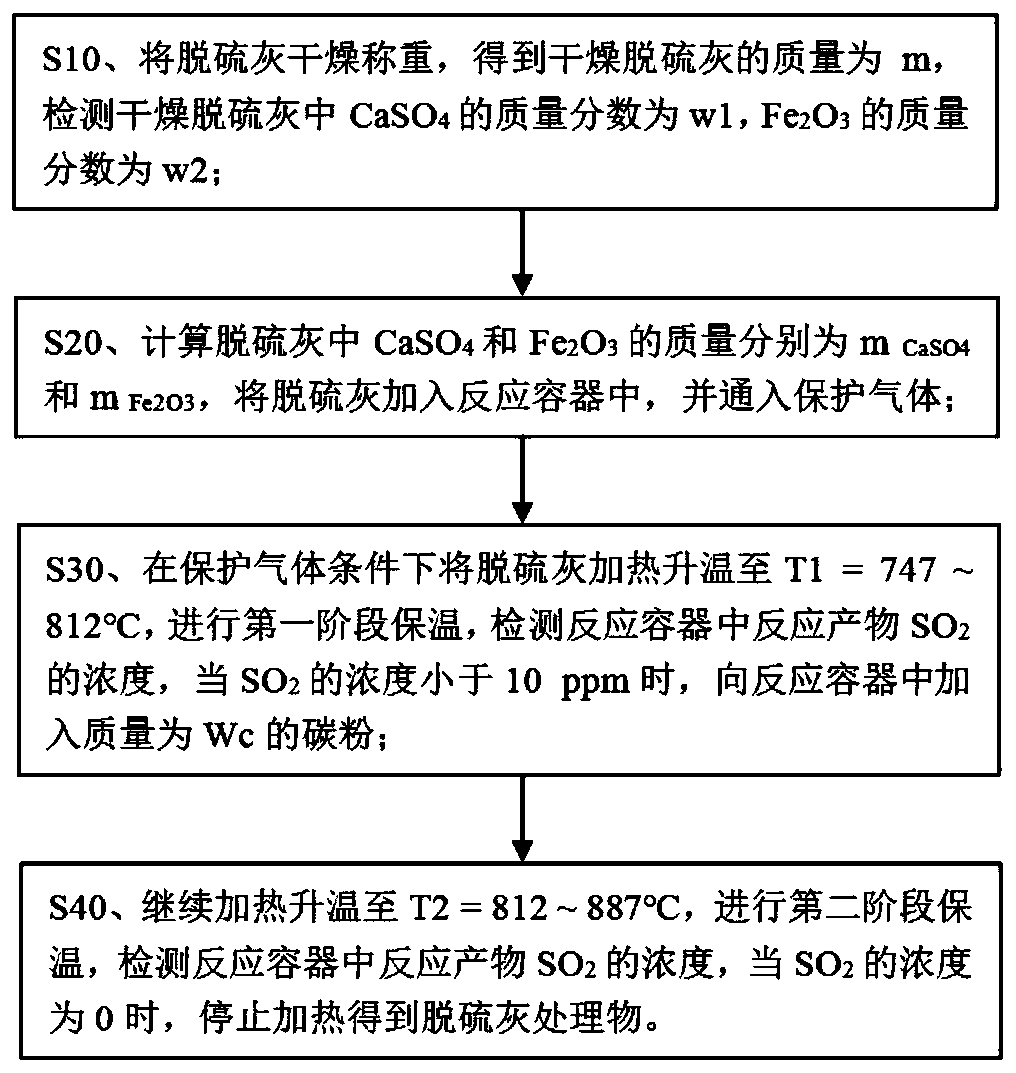

[0044] Such as figure 1 Shown, the concrete steps of a kind of desulfurization ash processing method of the present invention are as follows:

[0045] S10. Weigh 500 g of raw material desulfurization ash after vacuum drying at 105° C. for 4 hours to obtain dry desulfurization ash. Take dry desulfurization ash with a mass of m=100 g, and detect CaSO in the dry desulfurization ash 4 The mass fraction of Fe is w1=2.50%, Fe 2 o 3 The mass fraction of w2=1.21%;

[0046] S20, calculate CaSO in dry desulfurization ash 4 and Fe 2 o 3 The mass of each is m CaSO4 = 2.50g and m Fe2O3 = 1.21g, dry desulfurization ash is added in the reaction vessel, pass into the reaction vessel the oxygen in the protective gas discharge vessel, and described protective gas is inert gas or N 2 Gas, the shielding gas in this embodiment is N 2 Gas, the gas flow rate is Q1=0.5L / min;

[0047] S30. Under the condition of protective gas, heat the dry desulfurized ash to T1 temperature, the heating rat...

Embodiment 2

[0075] The basic content of this embodiment is the same as that of Embodiment 1, except that the specific steps of a desulfurization ash treatment method of this embodiment are as follows:

[0076]S10. Weigh 500 g of raw material desulfurization ash after vacuum drying at 105° C. for 4 hours to obtain dry desulfurization ash. Take dry desulfurization ash with a mass of m=100 g, and detect CaSO in the dry desulfurization ash 4 The mass fraction of Fe is w1=2.50%, Fe 2 o 3 The mass fraction of w2=1.21%;

[0077] S20, calculate CaSO in dry desulfurization ash 4 and Fe 2 o 3 The mass of each is m CaSO4 = 2.50g and m Fe2O3 = 1.21g, dry desulfurization ash is added in the reaction vessel, pass into the reaction vessel the oxygen in the protective gas discharge vessel, and described protective gas is inert gas or N 2 Gas, the shielding gas in this embodiment is N 2 Gas, the gas flow rate is Q1=0.5L / min;

[0078] S30. Under the condition of protective gas, heat the dry desulf...

Embodiment 3

[0083] The basic content of this embodiment is the same as that of Embodiment 1, except that the specific steps of a desulfurization ash treatment method of this embodiment are as follows:

[0084] S10. Weigh 500 g of raw material desulfurization ash after vacuum drying at 105° C. for 4 hours to obtain dry desulfurization ash. Take dry desulfurization ash with a mass of m=100 g, and detect CaSO in the dry desulfurization ash 4 The mass fraction of Fe is w1=2.50%, Fe 2 o 3 The mass fraction of w2=1.21%;

[0085] S20, calculate CaSO in dry desulfurization ash 4 and Fe 2 o 3 The mass of each is m CaSO4 = 2.50g and m Fe2O3 = 1.21g, dry desulfurization ash is added in the reaction vessel, pass into the reaction vessel the oxygen in the protective gas discharge vessel, and described protective gas is inert gas or N 2 Gas, the shielding gas in this embodiment is N 2 Gas, the gas flow rate is Q1=0.5L / min;

[0086] S30. Under the condition of protective gas, heat the dry desul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com