A kind of high nitrogen type hot work die steel and its preparation method

A technology of hot work die steel and high nitrogen type, which is applied in the field of hot work die steel, can solve the problems of low service temperature and insufficient strength, achieve fine dispersion of carbides, uniform structure, and improve mechanical properties and performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

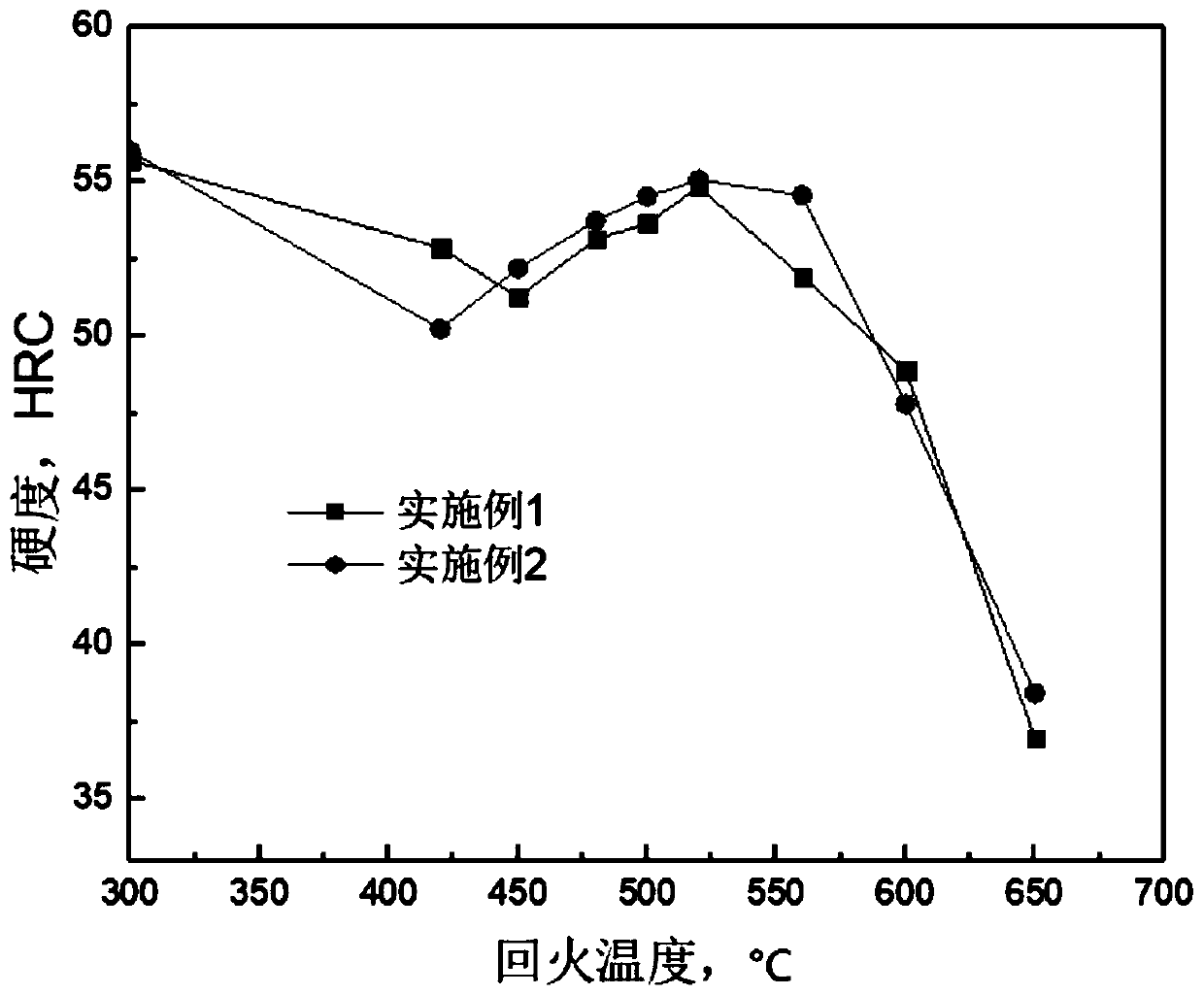

Embodiment 1

[0044] The steel chemical composition of high nitrogen type hot work die steel in the present embodiment is as follows (by weight percentage):

[0045] C Si mn P S Cr Mo V N 0.37% 0.97% 0.41% 0.008% 0.004% 5.48% 1.33% 1.02% 0.0170%

[0046] The preparation method of high nitrogen type hot work die steel in the present embodiment is as follows:

[0047] (1) Smelting: Smelting is carried out in an induction furnace according to the above-mentioned ratio of alloy elements, and the melting temperature is 1550°C, and cast into electrode rods.

[0048] (2) Forging: Using a multi-stage heating method, the above-mentioned steel ingot is heated to 1180°C for multi-directional forging processing, and the forging method with two piers and two draws is adopted, and the final forging temperature is 900°C;

[0049] (3) Cooling: Controlled cooling of the forged billet after forging, using oil cooling or water cooling to quickly cool to about 400°C, and th...

Embodiment 2

[0053] The steel chemical composition of high nitrogen type hot work die steel in the present embodiment is as follows (by weight percentage):

[0054] C Si mn P S Cr Mo V N 0.40% 1.12% 0.44% 0.008% 0.003% 5.33% 1.3% 1.01% 0.0294%

[0055] The preparation method of the high-nitrogen type hot work die steel in this embodiment is the same as that of the above-mentioned embodiment 1.

Embodiment 3

[0057]The steel chemical composition of high nitrogen type hot work die steel in the present embodiment is as follows (by weight percentage):

[0058] C Si mn P S Cr Mo V N 0.37% 0.80% 0.30% 0.009% 0.004% 5.0% 1.20% 0.80% 0.0150%

[0059] The preparation method of the high-nitrogen type hot work die steel in this embodiment is the same as that of the above-mentioned embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com