Novel textile structure composite material and preparation process and application thereof

A technology of composite materials and textile structures, applied in textiles, papermaking, textiles, fabrics, etc., can solve the problems of composite materials such as single functionality, and achieve the effects of high-efficiency quality, excellent strength, and convenient preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

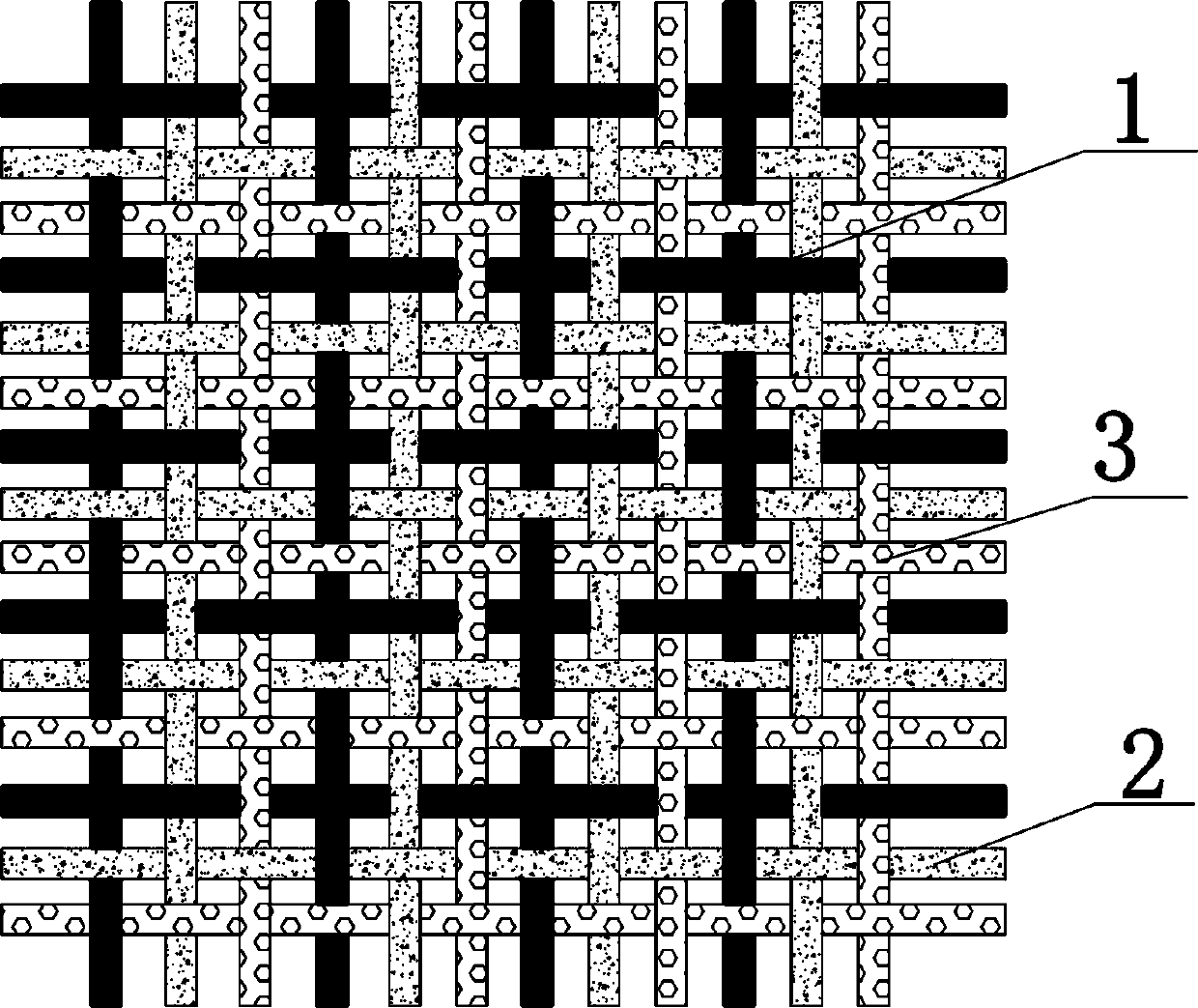

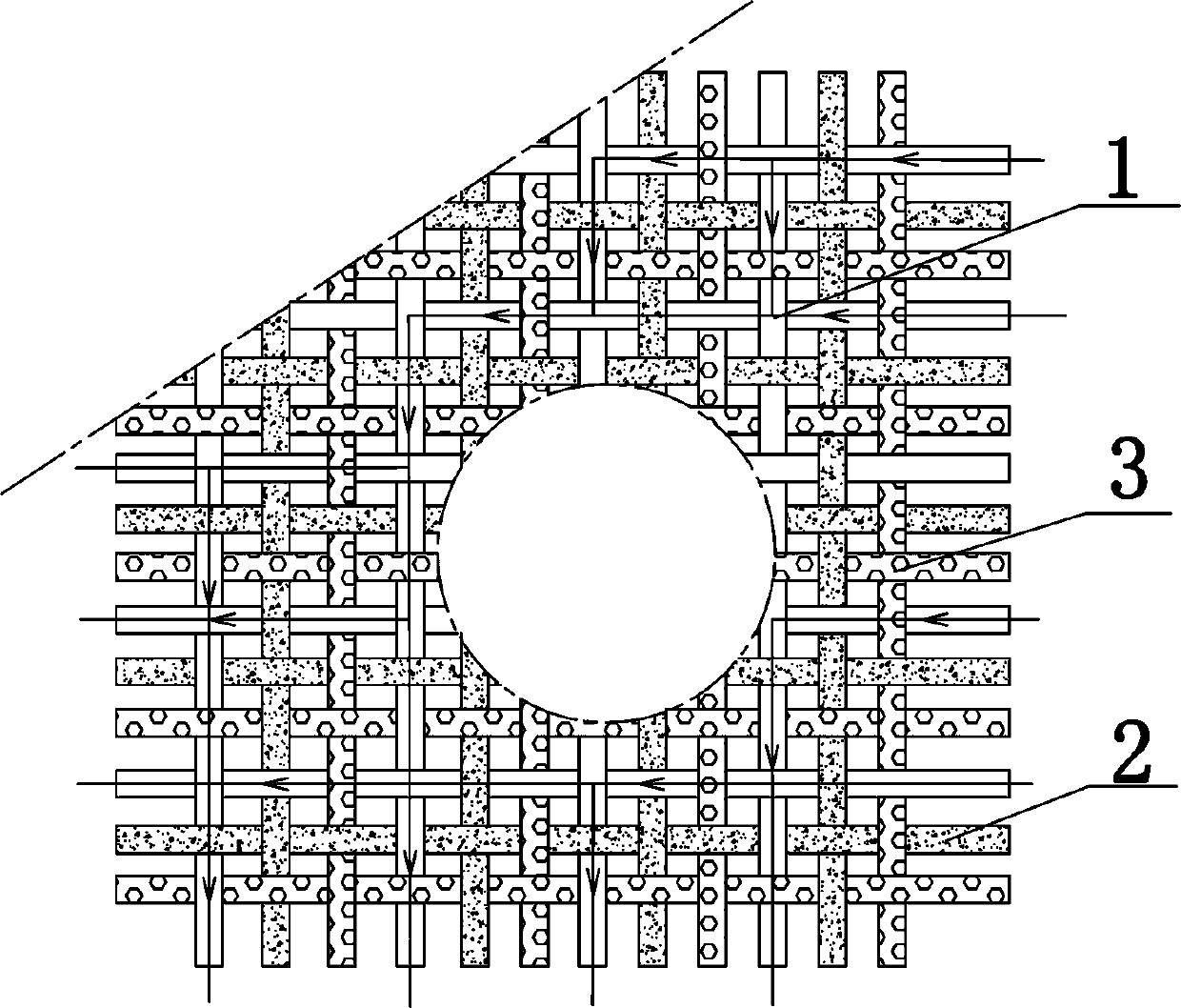

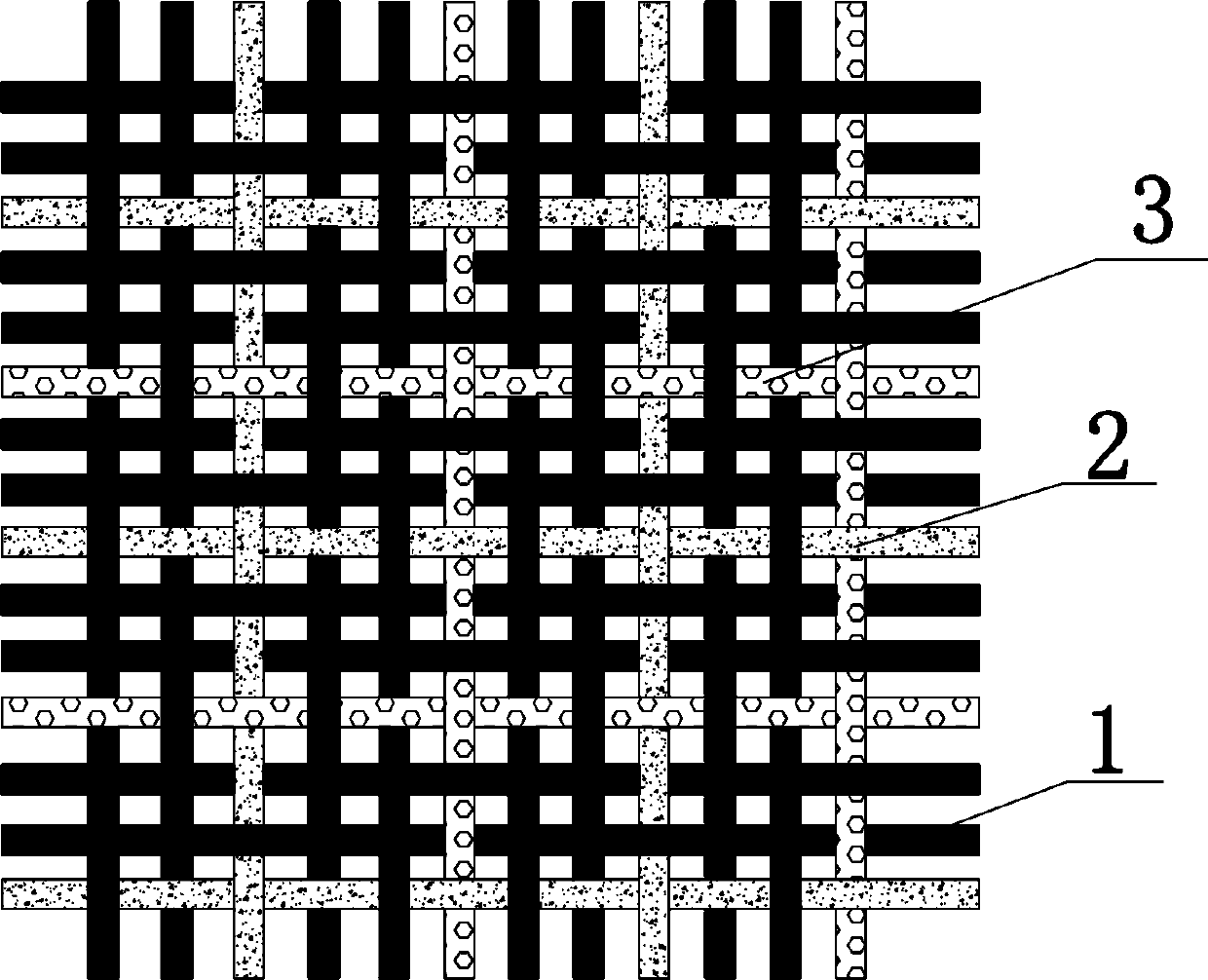

[0097] The composition of the composite material is calculated by mass percentage, including 60-90% of the first fiber 1, 10-20% of the second fiber 2 and 10-20% of the third fiber 3; the first fiber 1 is white One or more of steel fiber, copper fiber and silver fiber;

[0098] The flexible braided material of the composite material is manufactured into shape after shearing, and is applied to electromagnetic shielding.

[0099] In this embodiment, the composite material achieves the electromagnetic shielding function by reducing the ratio of the conventional second fiber 2 and the third fiber 3 , increasing the ratio of the first fiber 1 , especially adjusting the ratio of the third fiber 3 .

[0100] In this embodiment, according to different occasions and requirements, the first fiber 1 may be copper fiber or white steel fiber, etc.

[0101] In this embodiment, the composite material produced has the characteristics of conventional cloth, and can be manufactured and shaped ac...

Embodiment 2

[0103] The composition of the composite material is calculated by mass percentage, including 60-90% of the first fiber 1, 10-20% of the second fiber 2 and 10-20% of the third fiber 3; the first fiber 1 is white One or more of steel fiber, copper fiber and silver fiber;

[0104] The flexible braided material of the composite material is used as an electrode, placed in the water body to be treated at a preset distance, electrified, and the redox reaction of the water body is carried out, and is applied to purify the water body.

[0105] In this example, the composite material achieves the function of conduction by reducing the ratio of the conventional second fiber 2 and the third fiber 3, increasing the ratio of the first fiber 1, especially adjusting the ratio of the third fiber 3, and then used for water disinfection .

[0106] In this embodiment, the first fiber 1 may be white steel fiber.

[0107] In this embodiment, the composite material made of this structure can be ar...

Embodiment 3

[0109] The composition of the composite material is calculated by mass percentage, including 60-90% of the first fiber 1, 10-20% of the second fiber 2 and 10-20% of the third fiber 3; the first fiber 1 is white One or more of steel fiber, copper fiber and silver fiber;

[0110] The flexible braided material of the composite material is placed in the environment, connected with an electrostatic generator, realizes the adsorption of particles, and is applied to air purification.

[0111] In this example, the composite material achieves the function of conduction by reducing the ratio of the conventional second fiber 2 and the third fiber 3, increasing the ratio of the first fiber 1, especially adjusting the ratio of the third fiber 3, and then used for electrostatic dust removal .

[0112] In this embodiment, the first fiber 1 may be white steel fiber, copper fiber, silver fiber and the like.

[0113] In this embodiment, the composite material realizes the adsorption of dust a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com