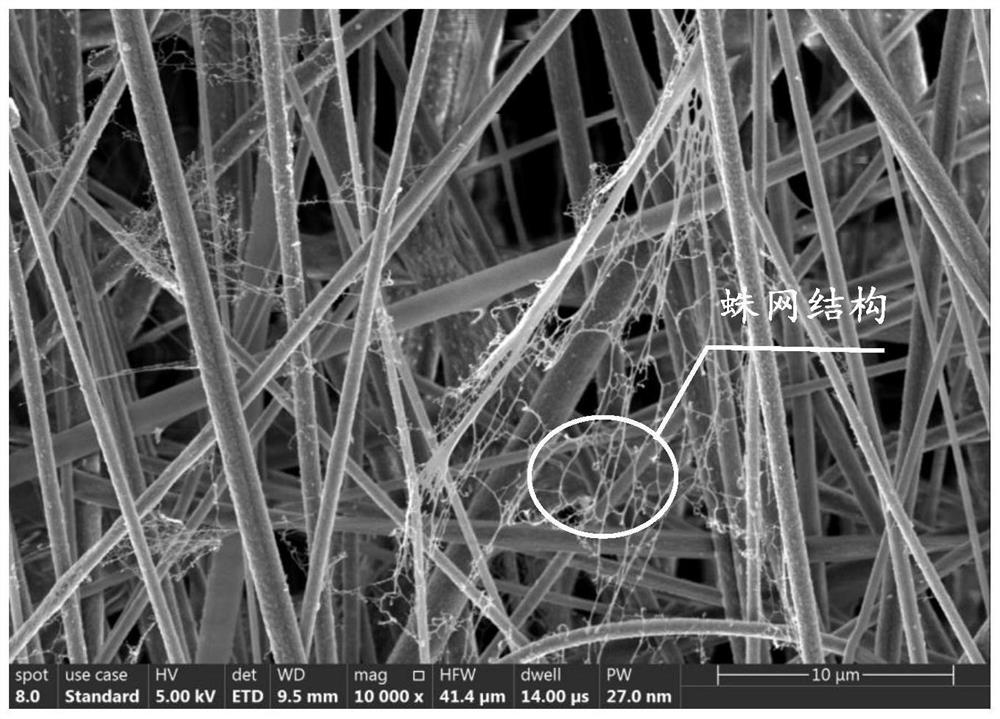

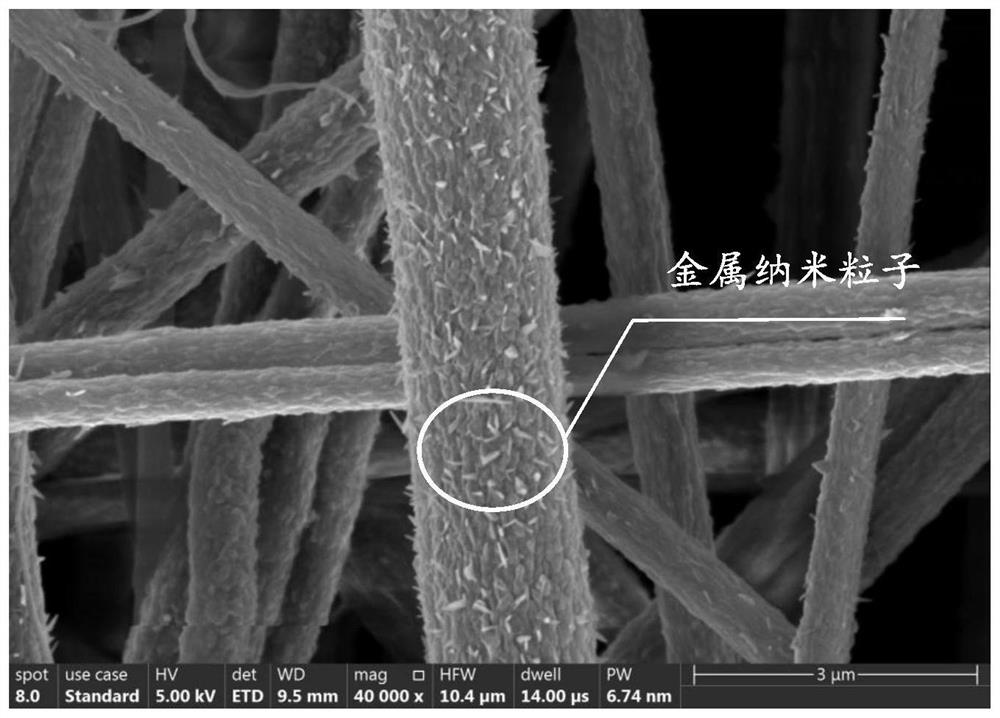

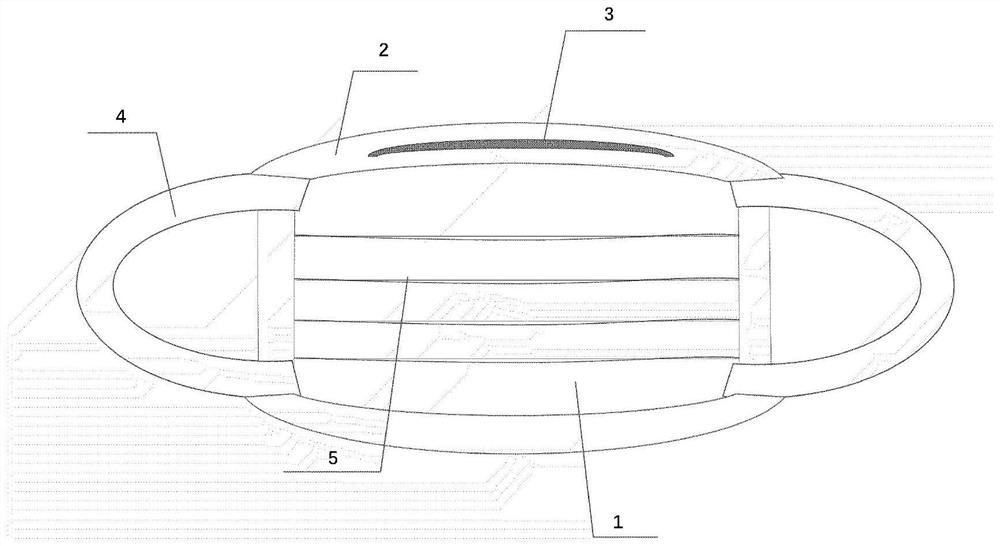

Metal nano self-assembly fiber material as well as preparation method and application thereof

A fiber material and metal nanotechnology, applied in the field of electrospinning micro-nano fiber medical protective materials and its preparation, can solve the problems of uneven dispersion of fibers, affecting production efficiency, complicated preparation process, etc., and achieve high protection and long service life Prolonged, easy-to-prepare effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Weigh 1g of stabilizer polyvinylpyrrolidone into 20g of N,N-dimethylformamide solvent, stir at 80°C for 4h to dissolve, then cool to room temperature, add 1.5g of silver nitrate in a dark environment, and stir at room temperature Dissolved for 12h to obtain silver nanoparticles, the solution was left to stand for defoaming. Weigh 7g of polyvinylidene fluoride, add it to 20.5g of N,N-dimethylformamide solvent, stir at 80°C for 4h to dissolve, then cool to room temperature, add silver nanoparticles in a dark environment, at 80°C Under stirring for 1 h, a silver nanoparticle-doped polyvinylidene fluoride precursor spinning solution was prepared, and the solution was allowed to stand for defoaming. The mass fraction of polyvinylpyrrolidone is 2%, the mass fraction of polyvinylidene fluoride is 14%, and the mass fraction of silver nitrate is 3%.

[0055] Inject the spinning solution into the syringe pump, use a 17G needle, adjust the distance from the spinning needle tip to...

Embodiment example 2

[0058] Weigh 1g of stabilizer polyvinylpyrrolidone into 20g of N,N-dimethylformamide solvent, stir at 80°C for 4h to dissolve, then cool to room temperature, add 2g of silver nitrate in a dark environment, stir and dissolve at room temperature After 12 h, silver nanoparticles were obtained, and the solution was left to stand for defoaming. Weigh 7g of polyvinylidene fluoride, add it to 20g of N,N-dimethylformamide solvent, stir at 80°C for 4h to dissolve, then cool to room temperature, add silver nanoparticles in a dark environment, and at 80°C After stirring for 1 h, the silver nanoparticle-doped polyvinylidene fluoride precursor spinning solution was prepared, and the solution was allowed to stand for defoaming. The mass fraction of polyvinylpyrrolidone is 2%, the mass fraction of polyvinylidene fluoride is 14%, and the mass fraction of silver nitrate is 4%.

[0059] Inject the spinning solution into the syringe pump, use a 17G needle, adjust the distance from the spinning ...

Embodiment example 3

[0062] Weigh 1g of stabilizer polyvinylpyrrolidone into 20g of N,N-dimethylformamide solvent, stir at 80°C for 4h to dissolve, then cool to room temperature, add 2.5g of silver nitrate in a dark environment, and stir at room temperature Dissolved for 12h to obtain silver nanoparticles, the solution was left to stand for defoaming. Weigh 7g of polyvinylidene fluoride, add it to 19.5g of N,N-dimethylformamide solvent, stir at 80°C for 4h to dissolve, then cool to room temperature, add silver nanoparticles in a dark environment, and at 80°C Under stirring for 1 h, a silver nanoparticle-doped polyvinylidene fluoride precursor spinning solution was prepared, and the solution was allowed to stand for defoaming. The mass fraction of polyvinylpyrrolidone is 2%, the mass fraction of polyvinylidene fluoride is 14%, and the mass fraction of silver nitrate is 5%.

[0063] Inject the spinning solution into the syringe pump, use a 17G needle, adjust the distance from the spinning needle ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com