Method for improving stability of strip coal pillar

A striped coal pillar and stability technology, which is applied in earthwork drilling, ground mining, shaft lining, etc., can solve the problems of instability and damage, and the width of the striped coal pillar is not enough to support, so as to improve the recovery rate and improve the resistance Deformation ability, good stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

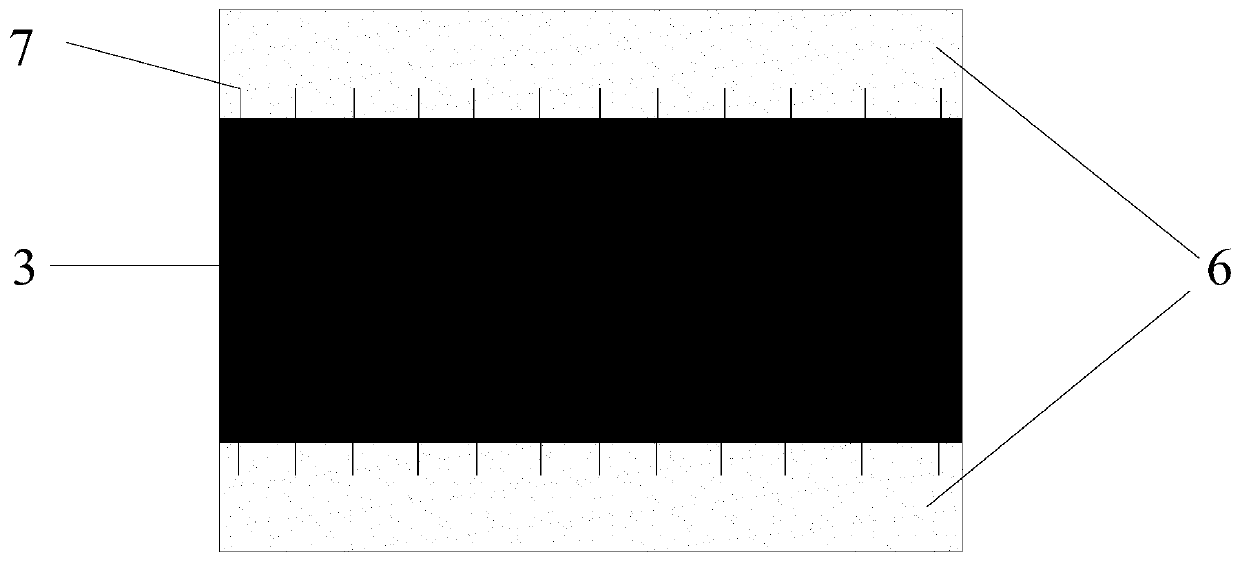

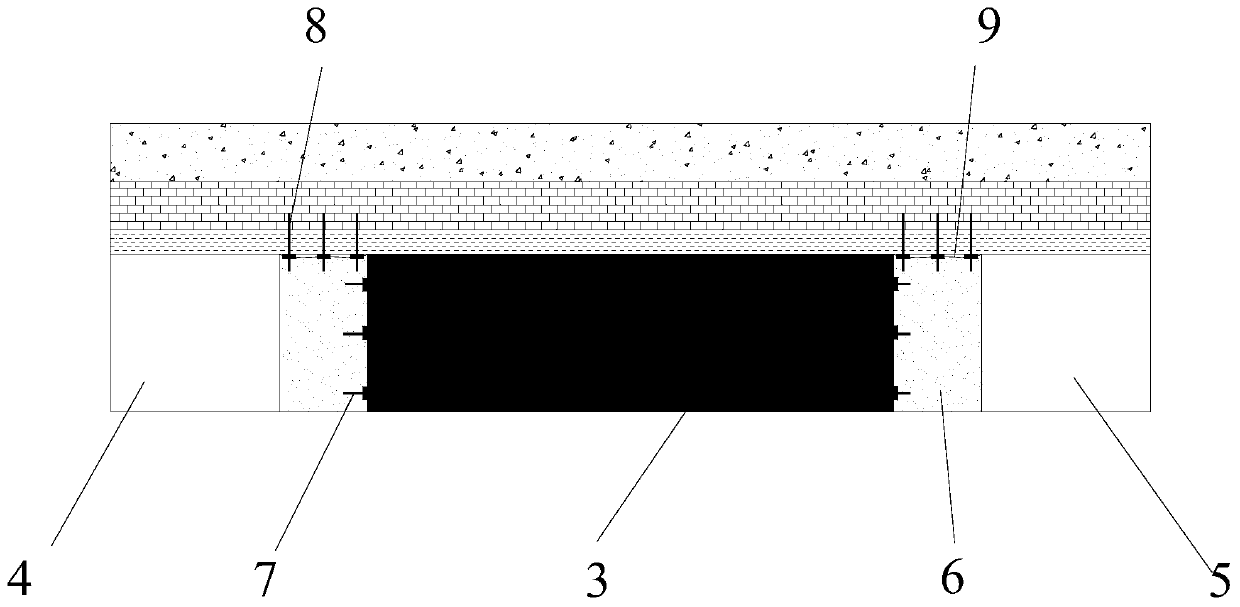

[0038] The method of the present invention is applied to a certain mine in Shandong. Taking the strip coal pillar between the 3104 working face and the 3105 working face as an example, the thickness of the coal seam is 7.6m, and the mining depth is 665m.

[0039] The specific mining method is as follows:

[0040] The first step is to determine the roadway layout of the 3104 working face in combination with the roof and floor conditions of the coal seam. The transportation roadway of the 3104 strip working face adopts a rectangular section with a net section size of 4000×3300mm.

[0041] In the second step, after the transport roadway is excavated every 5m, the roadway expansion excavation is carried out along the side of the strip coal pillar in the transport roadway to form a roadway expansion area with a width of 10m.

[0042] Step 3: Reinforce the roadway expansion area. When the roadway expansion area is reinforced, the roof of the roadway is supported by laying metal mesh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com