Hybrid power type planetary gear slope slipping-preventing mechanism

A planetary gear and hybrid technology, applied in the field of vehicle engineering, can solve the problems of increasing the complexity of the braking system, increasing the cost of the whole vehicle, and unreliable performance, and achieve the effects of reliable performance, simplified structure, and fast anti-slope response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

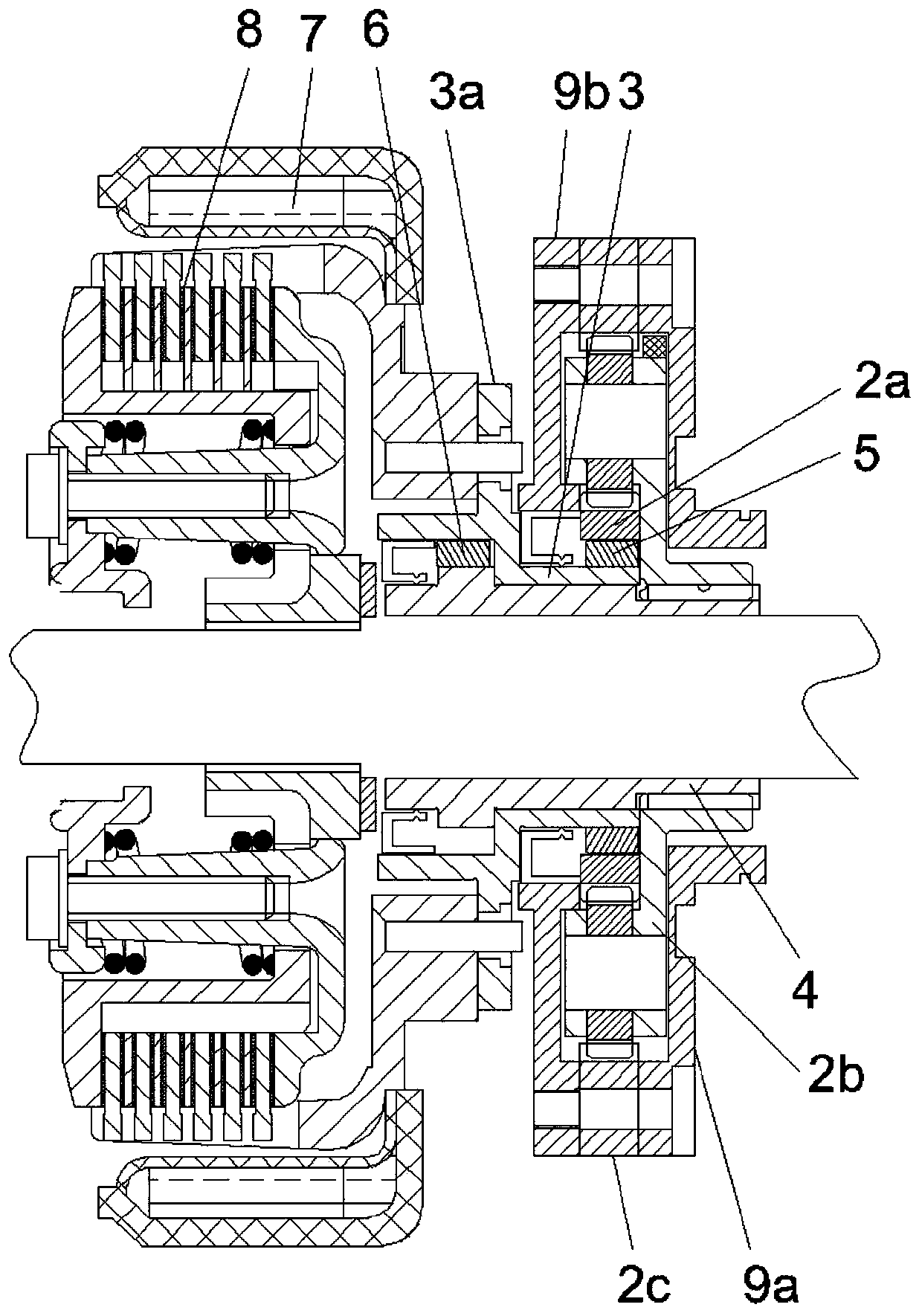

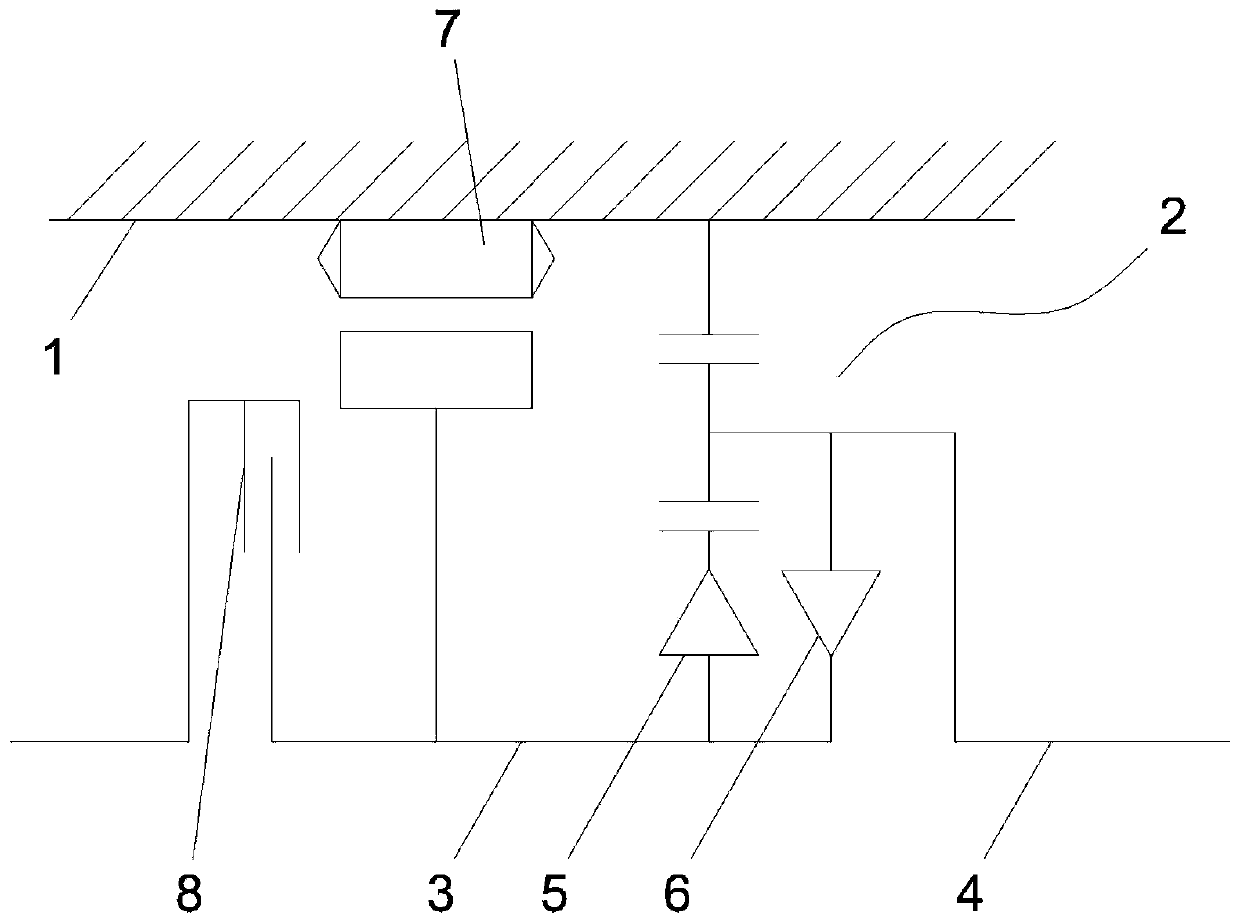

[0025] figure 1 It is a structural schematic diagram of the present invention; figure 2 It is a schematic structural diagram of the principle of the present invention;

[0026] As shown in the figure, the hybrid planetary gear anti-slope mechanism in this embodiment includes a frame 1, a planetary transmission mechanism 2, a power input member 3, a power output member 4, a No. 1 clutch 5, a No. 2 clutch 6 and Motor 7; any sequence combination of the sun gear 2a, the planet carrier 2b, and the ring gear 2c in the planetary transmission mechanism corresponds to the power input end, the power output end and the intermediate transmission component respectively, and the described motor 7 inputs power to The power input part 3, the power input part 3 cooperates with the power input end through the No. 1 clutch to realize power transmission, and the power input part 3 cooperates with the power output part 4 through the No. 2 clutch to realize power transmission. The power output p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com