Ultrasonic enhanced heat transfer tank type cooling device utilizing microbubble emission boiling

A technology of ultrasonic strengthening and cooling device, used in heat transfer modification, heat exchange equipment, indirect heat exchangers, etc. Difficult to maintain, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

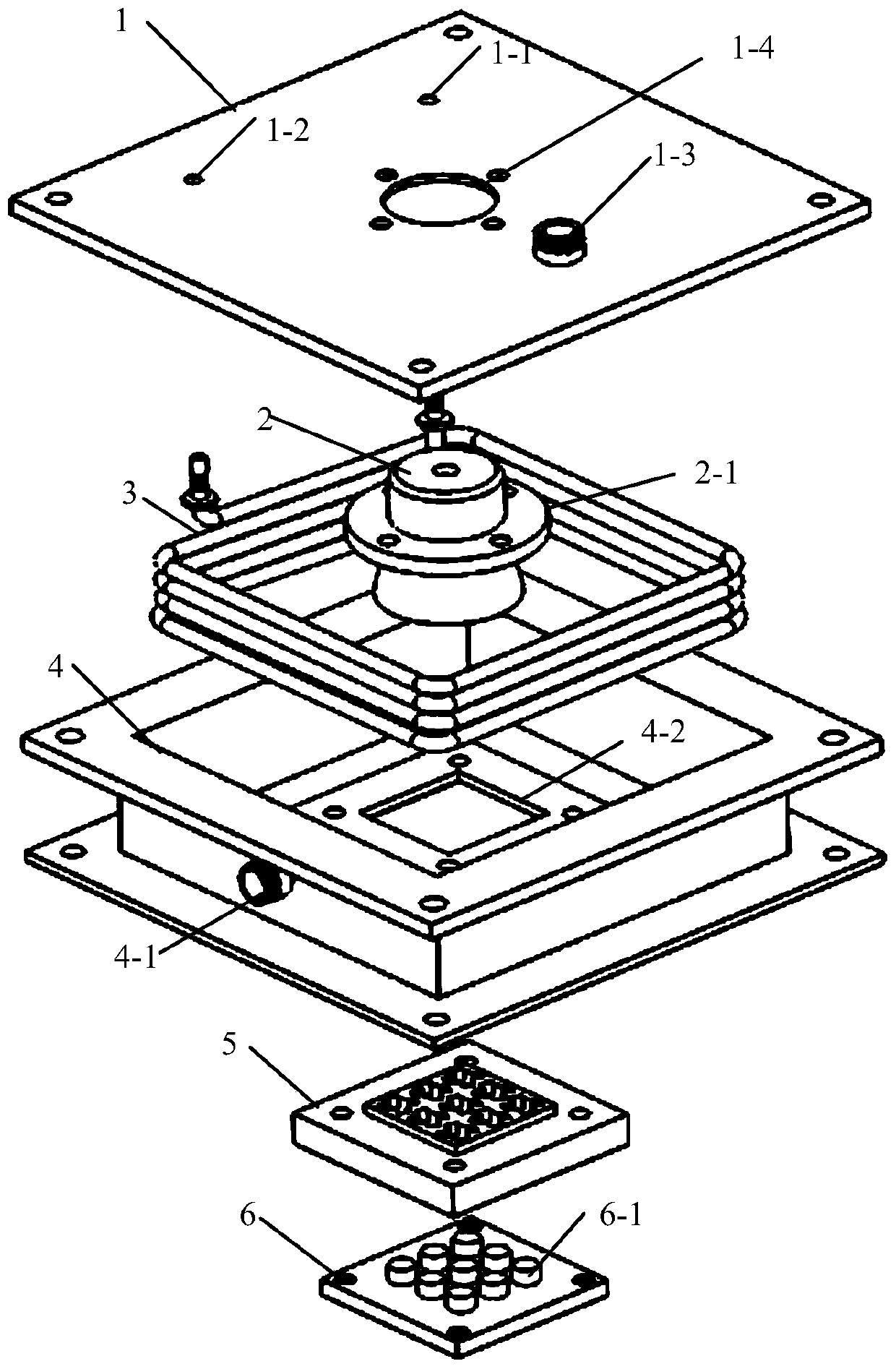

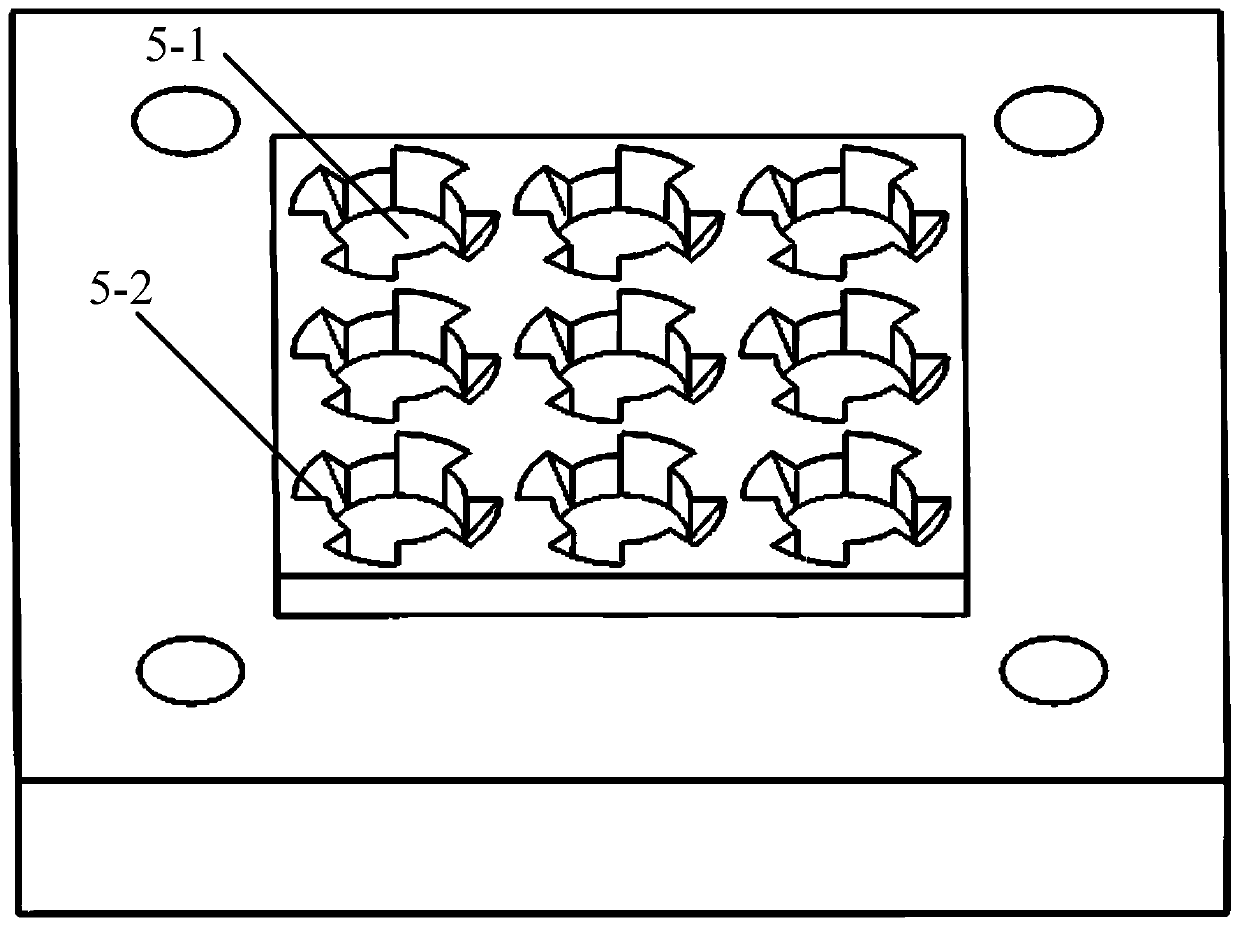

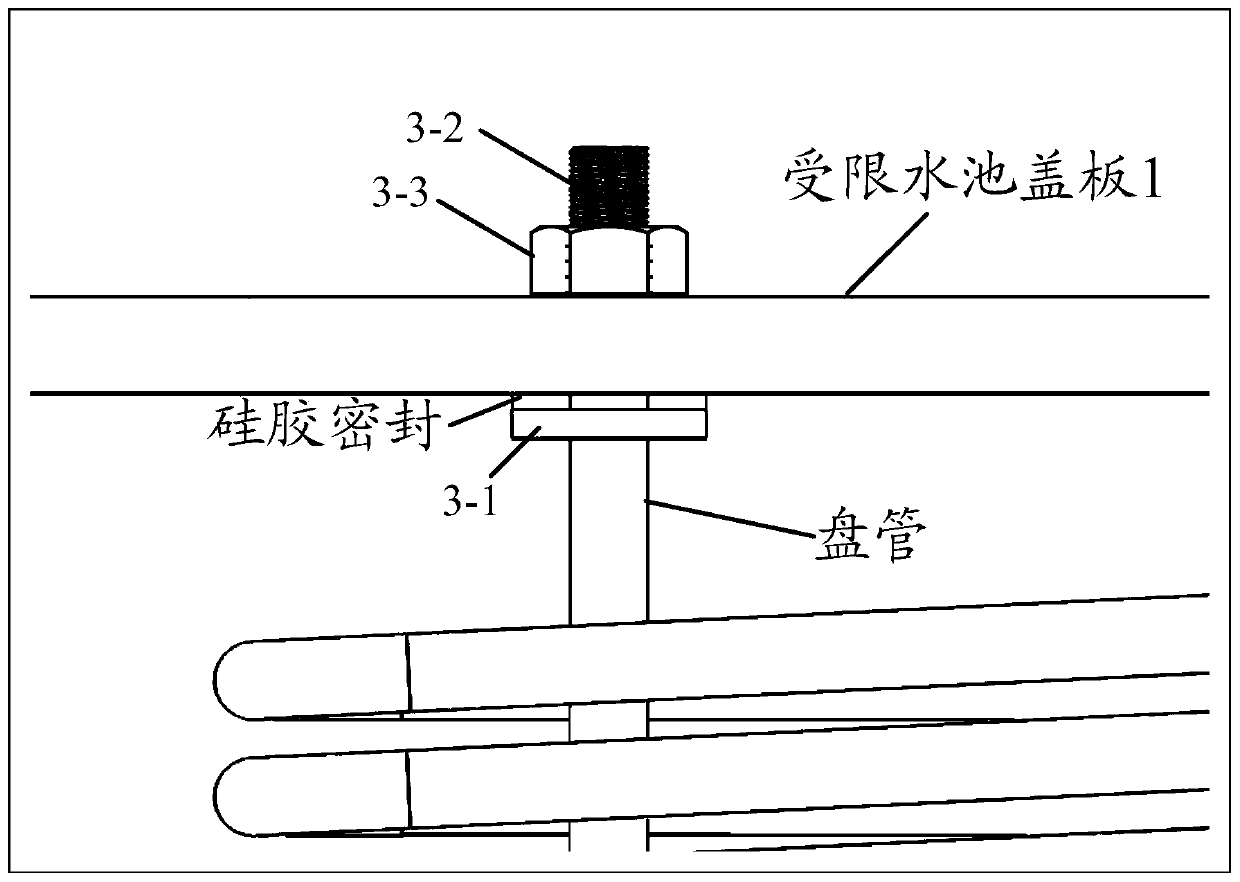

[0039] In order to make the above objects, features and advantages of the present application more obvious and comprehensible, the present application will be further described in detail below in conjunction with the accompanying drawings and specific implementation methods.

[0040]The current bubble miniaturization boiling cooling devices all adopt the method of flow boiling. The pipeline through which the cooling medium flows is the heat exchange channel. The heat exchange channel contacts the heating surface, and the cooling medium flow generates bubble miniaturization in the pipeline Boiling, the bubbles on the pipe wall experience rapid partial or top crushing process, accompanied by microbubble ejection and strong boiling noise, which in turn causes strong pressure oscillations, and equipment such as pipelines and water pumps are under strong pressure oscillations for a long time , will inevitably be damaged to a certain extent, reducing its service life.

[0041] In or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com