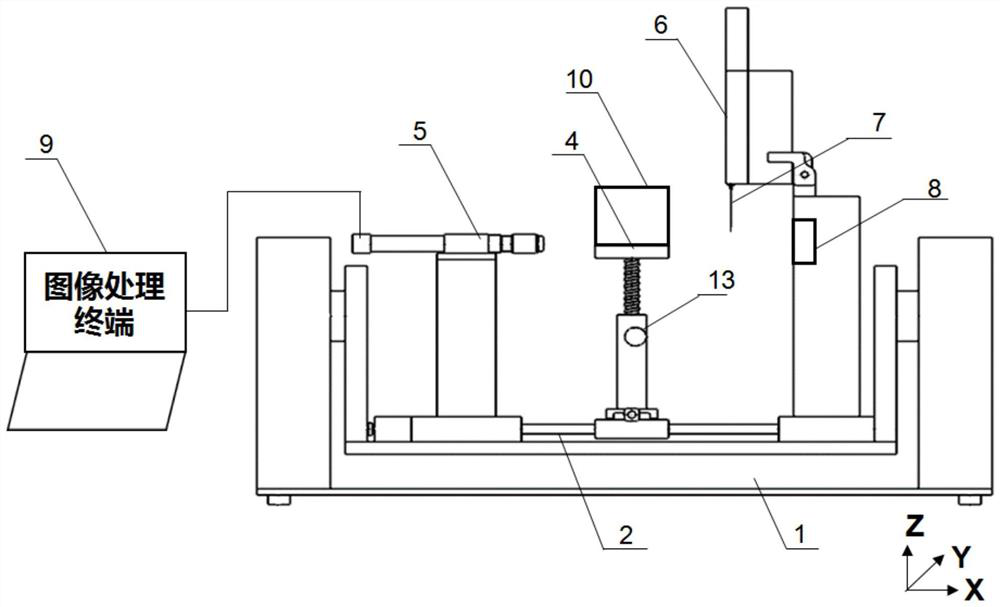

A device for measuring the frictional force of droplets on a solid surface

A solid surface and friction technology, applied in the field of interface friction devices and devices for measuring the friction of liquid droplets on solid surfaces, can solve the problems of experimental errors, large influence of droplet size, and low measurement accuracy, and achieve simple structure , The test process is convenient, and the effect of promoting mechanism research

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

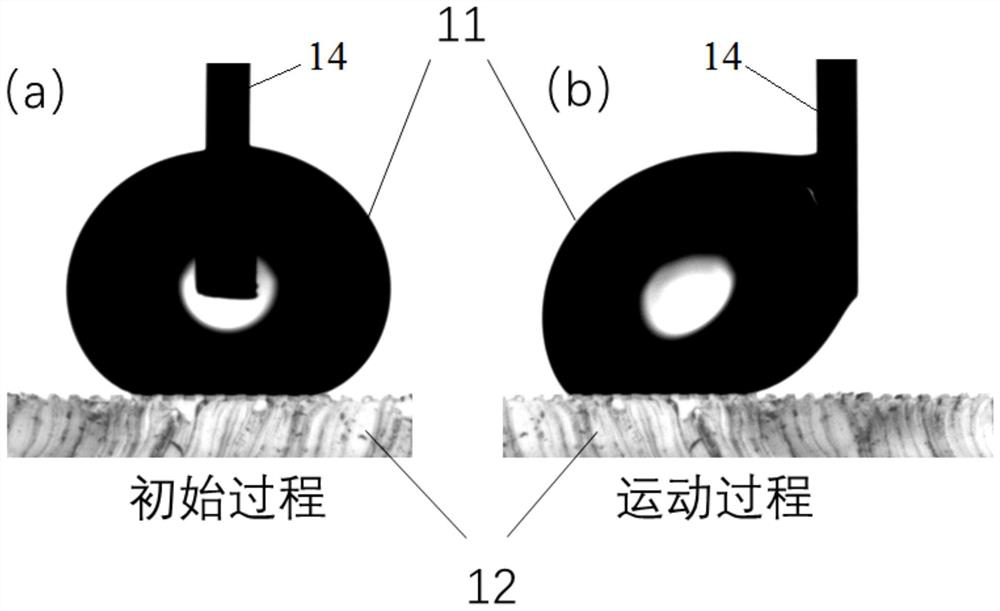

[0056] A device for measuring the frictional force of droplets on a solid surface as described above is used to test the frictional force between ultrapure water droplets 11 and a polydimethylsiloxane sample with a micron groove structure, comprising the following steps:

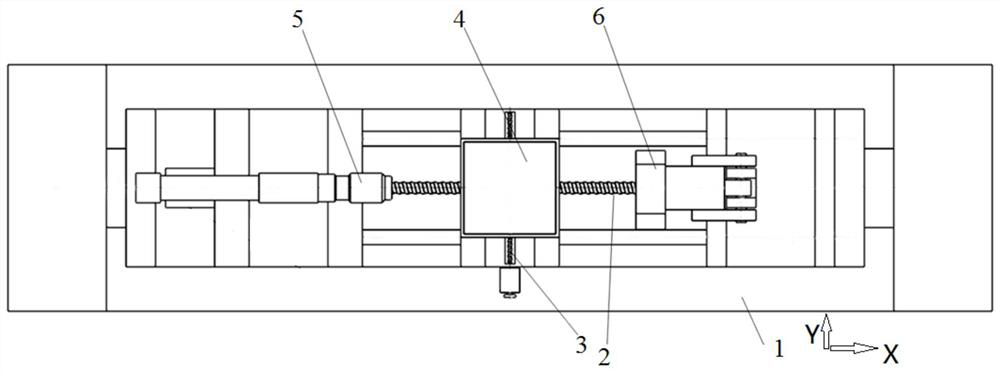

[0057] Step 1: Fix the solid sample 12 with a micron groove structure on the surface on the sample stage 4, the groove width of the groove structure is 50 microns, the groove pitch is 50 microns, and the groove height is 30 microns.

[0058] Step 2: Adjust the sample table 4 to the right below the needle tube 14 through the Y-direction screw nut linear slide 3 and the X-direction screw nut linear slide 2 of the three-dimensional mobile platform, and adjust the needle tube 14 to be close to the solid sample 12 through the lifting adjustment mechanism 6 At the center of the surface, the plunger of the injector is pushed through the control of the electric push rod, and 4 μL of droplet 11 is injected to the surf...

Embodiment 2

[0063] A device for measuring the frictional force of droplets on a solid surface as described above is used to test the frictional force between ultrapure water droplets and a copper oxide sample having a micron cone columnar array structure, comprising the following steps:

[0064] Step 1: Fix the solid sample 12 on the sample stage 4, the surface of the solid sample 12 has a conical array structure, the diameter of the bottom of the cone is 30 microns, and the height is 35 microns.

[0065] Step 2: Adjust the sample table 4 to the needle tube 14 through the Y-direction screw nut linear slide 3 and the X-direction screw nut linear slide 2 of the three-dimensional mobile platform, and adjust the needle tube 14 to the center of the surface of the solid sample 12 through the lifting adjustment mechanism 6 position, the piston rod of the injector is controlled by the electric push rod, and the 8 μL droplet 11 is injected to the surface of the solid sample 12 through the needle tu...

Embodiment 3

[0070] A device for measuring the frictional force of droplets on a solid surface is used to test the frictional force between ethylene glycol droplets and polydimethylsiloxane samples with a micron circular columnar array structure, comprising the following steps:

[0071] Step 1: Fix the solid sample 12 on the sample stage 4, the surface of the solid sample 12 has a cylindrical array structure, the diameter of the cylinder is 30 microns, and the height is 35 microns.

[0072] Step 2: Adjust the sample table 4 to the needle tube 14 through the Y-direction screw nut linear slide 3 and the X-direction screw nut linear slide 2 of the three-dimensional mobile platform, and adjust the needle tube 14 to the center of the surface of the solid sample 12 through the lifting adjustment mechanism 6 The position is controlled by the control software to push the piston rod of the sample injector, and inject 6 μL of droplet 11 to the surface of the solid sample 12 through the needle tube 14...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com