Electrode system for flat insulation sample breakdown test

An electrode system and breakdown test technology, which is applied in the field of electrode systems, can solve the problems of cumbersome sample replacement steps, strict sample shape and size requirements, poor contact between the sample and the electrode, etc., to improve electrical resistance and homogenize the electric field , the effect of reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

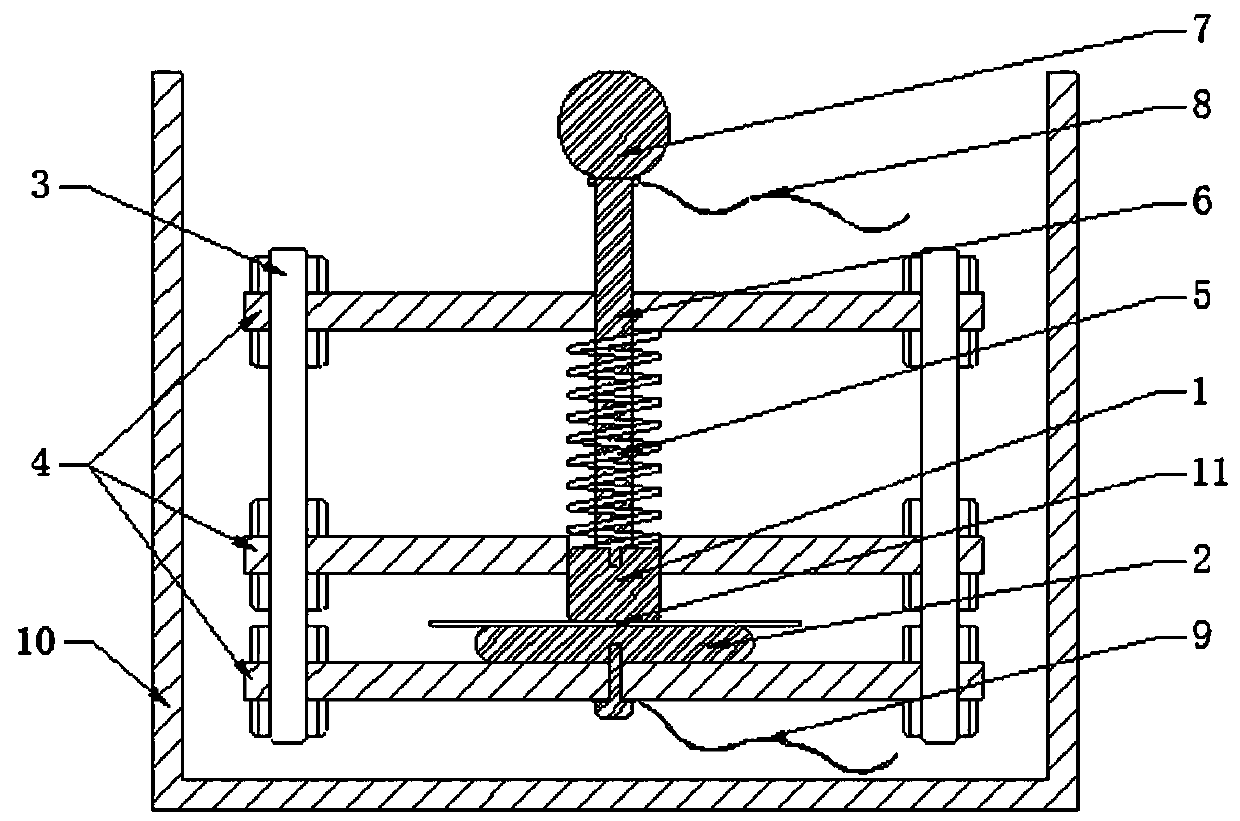

[0023] An electrode system for the breakdown test of a flat insulation sample, its composition includes: a test electrode, a support structure, an elastic structure, an electrode lead and a test container, the test electrode includes a high-voltage electrode and a ground electrode, and the high-voltage The sample is placed between the electrode and the ground electrode. The support structure includes a set of polytetrafluoroethylene rods and three pieces of rectangular plexiglass. The elastic structure is composed of a spring, a cylindrical rod and a pressure equalizing ball. The electrode lead includes a high voltage end lead and a ground end lead, the electrode system is placed in a test container filled with transformer oil, and the voltage equalizing ball and the ground electrode connection end pass through the high voltage end lead and the ground terminal leads are drawn out from the inside of the test container.

Embodiment 2

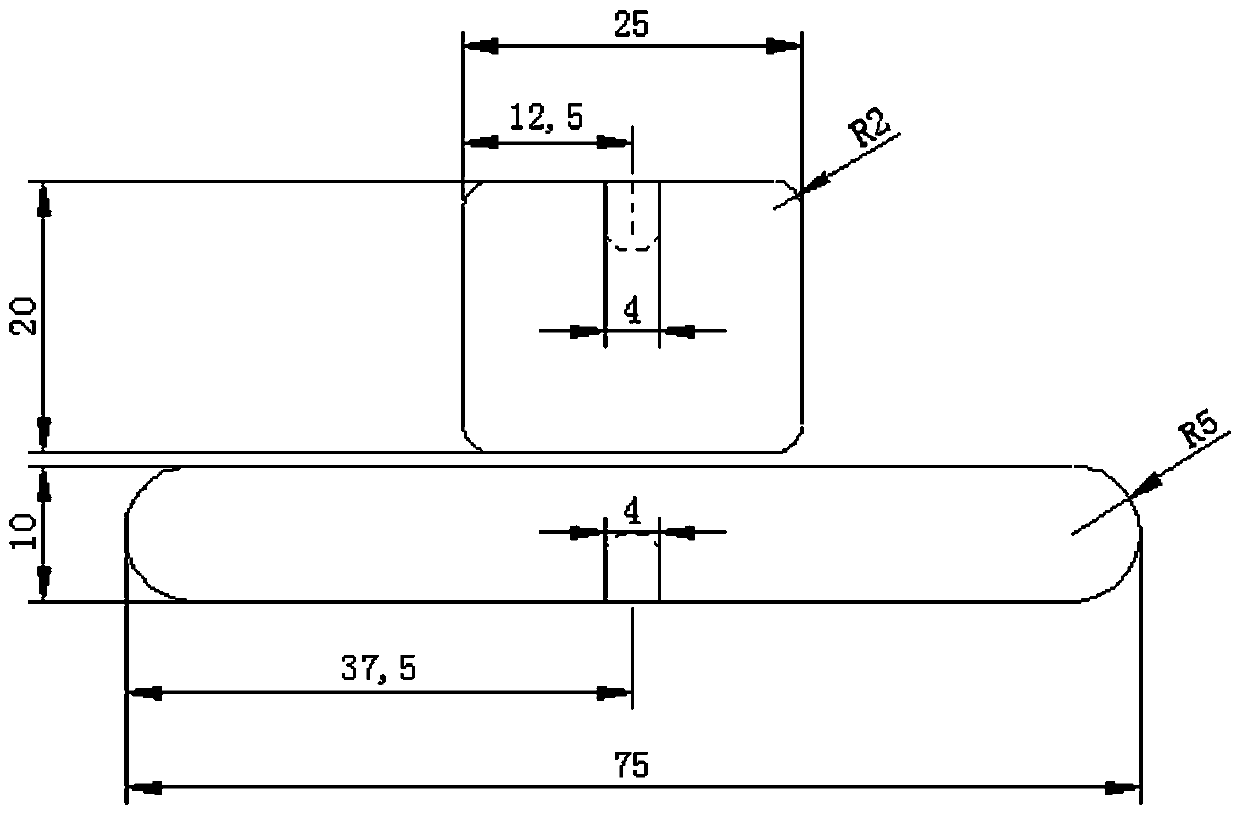

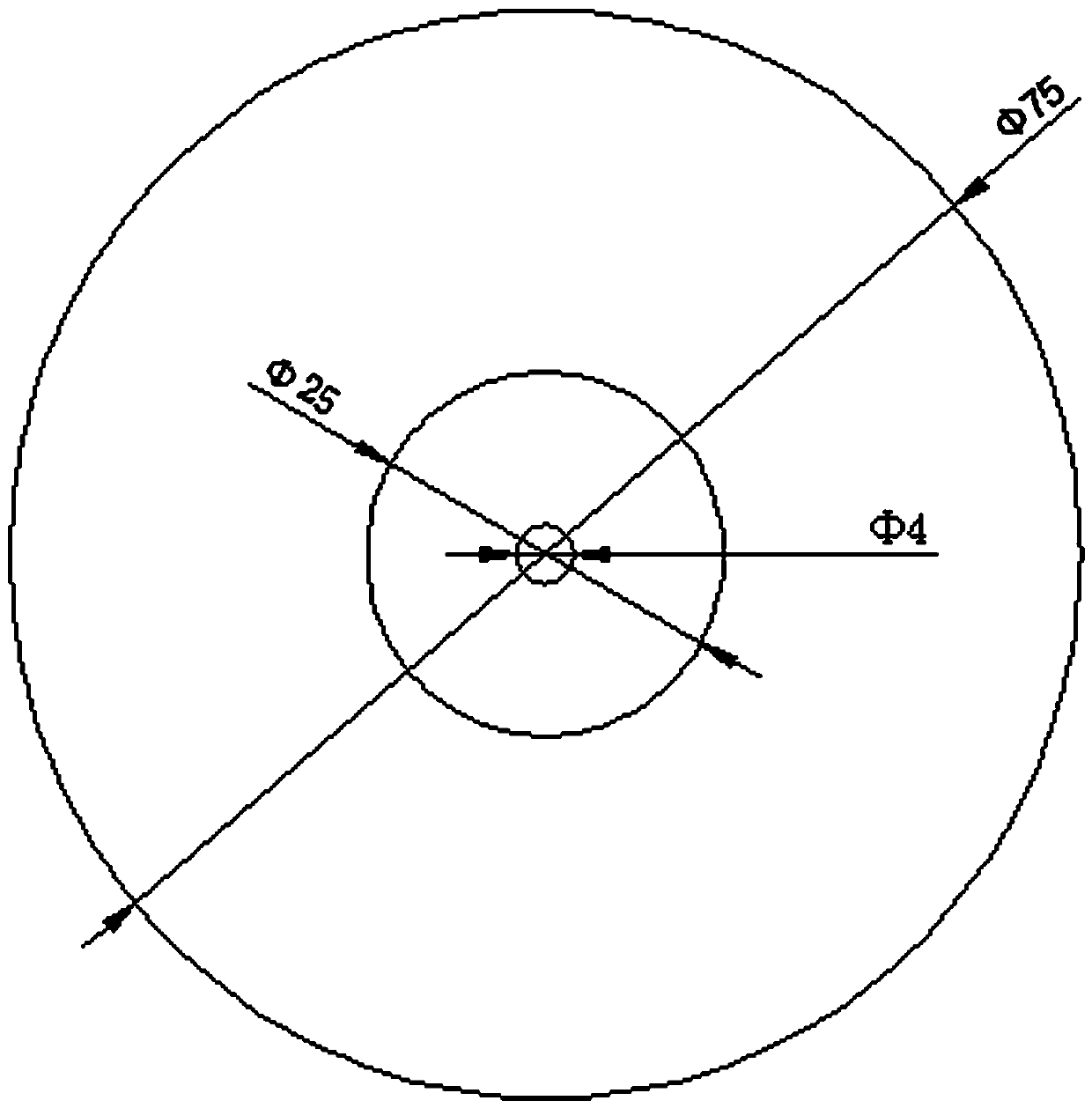

[0025] According to the electrode system used for the breakdown test of flat insulation samples described in Example 1, the high voltage electrode, the ground electrode, the cylindrical rod and the pressure equalizing ball are made of brass, and the The high-voltage electrode is a cylinder with a diameter of 25 mm, a height of 20 mm, and a chamfer of 2 mm. The ground electrode is a cylinder with a diameter of 75 mm, a height of 10 mm, and a chamfer of 5 mm. The described cylindrical rod is a cylinder with a diameter of 10 mm and a height of 100 mm. The equalizing ball is a 30mm diameter sphere.

Embodiment 3

[0027] According to the electrode system used for the breakdown test of the flat insulation sample described in embodiment 1 or 2, what the described supporting structure adopts is organic glass material, and three pieces of rectangular organic glass are 200 mm long, 100 mm wide, and 10 mm thick, respectively Drill four round holes with a diameter of 10mm at the four corners of the rectangular plexiglass at a distance of 12mm from both sides.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com