Method for predicting residual life of digital twin-driven aero-engine turbine disc

An aero-engine and life prediction technology, which is applied in the direction of prediction, electrical digital data processing, data processing applications, etc., can solve the problems of single working condition of the model, inaccurate prediction results of remaining life, and insufficient consideration of working condition changes, so as to reduce waste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

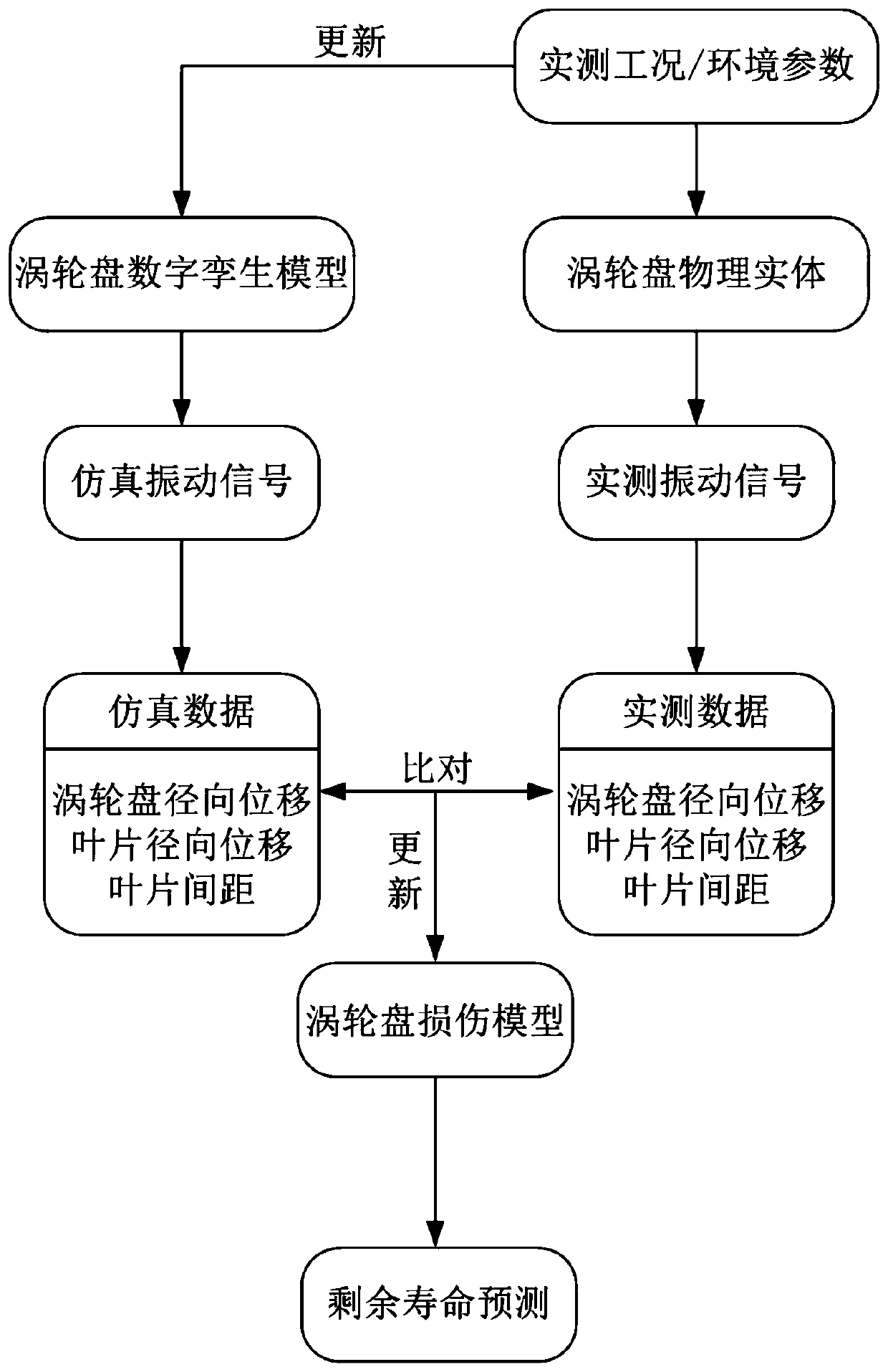

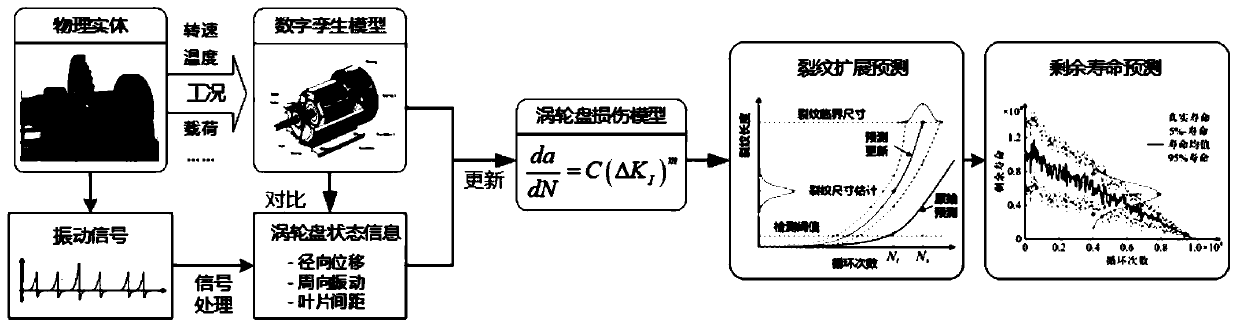

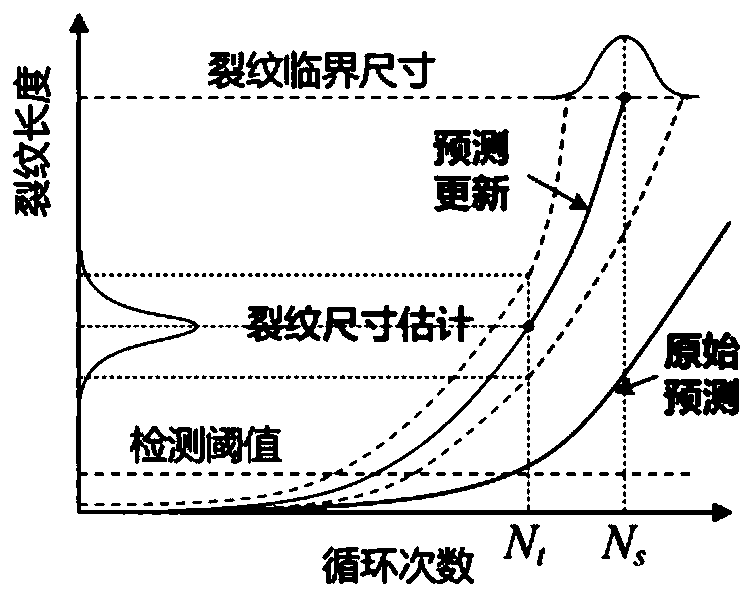

[0044] Such as figure 1 As shown, the method for predicting the remaining life of the aeroengine turbine disk driven by digital twins proposed by the present invention includes the following steps:

[0045] S1, constructing a digital twin model of an aeroengine turbine disk-rotor-support system;

[0046] S11, measure the geometric structure parameters of the turbine disc, shaft and main bearing of the aero-engine, query the material characteristic parameters, and perceive the initial working conditions / environmental parameters; the geometric structure of the turbine disc, shaft and main bearing of the aero-engine The parameters can be obtained from the drawing documents of the aero-engine turbine disc, shaft and main bearing; the material properties include at least the grade and mechanical properties of the materials used for the aero-engin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com