PERC battery assembly with high PID resistance and preparation method thereof

A battery component and resistance technology, which is applied in the field of solar cells, can solve the problems of poor performance of the battery against PID failure, and achieve the effects of improving the folding rate, optimizing the number of deposition cycles, and optimizing the refractive index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

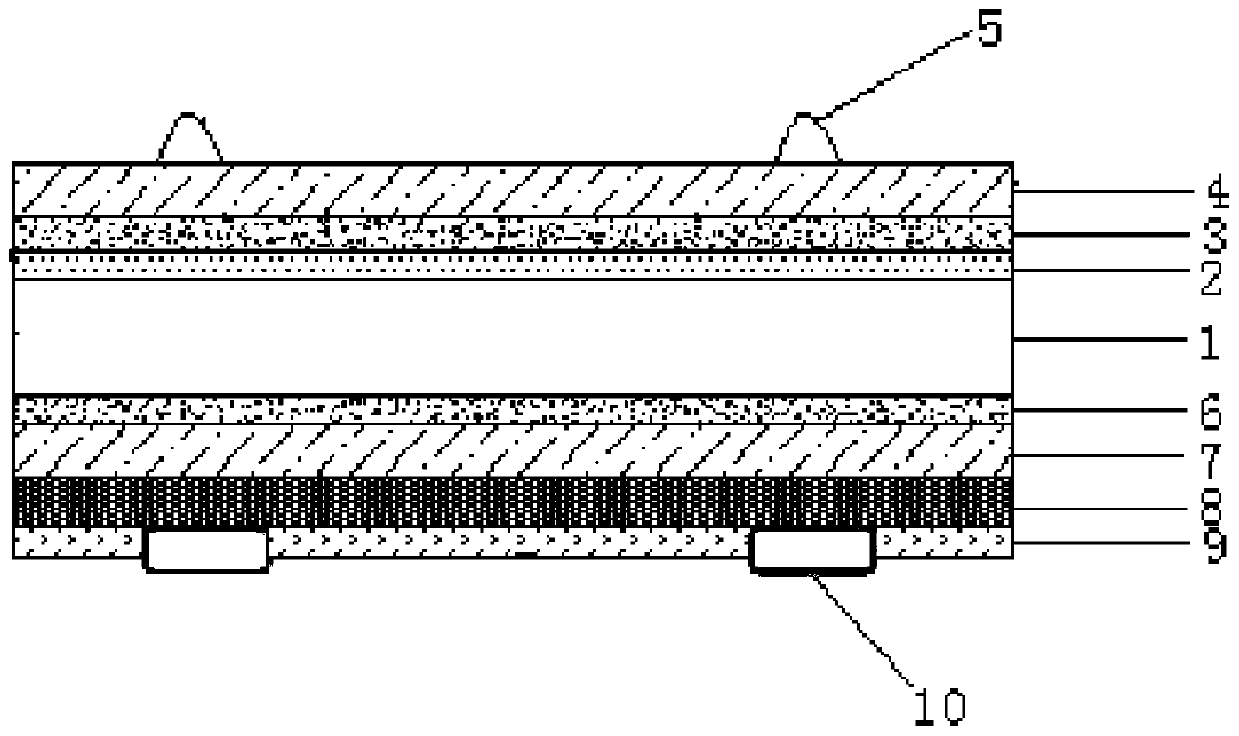

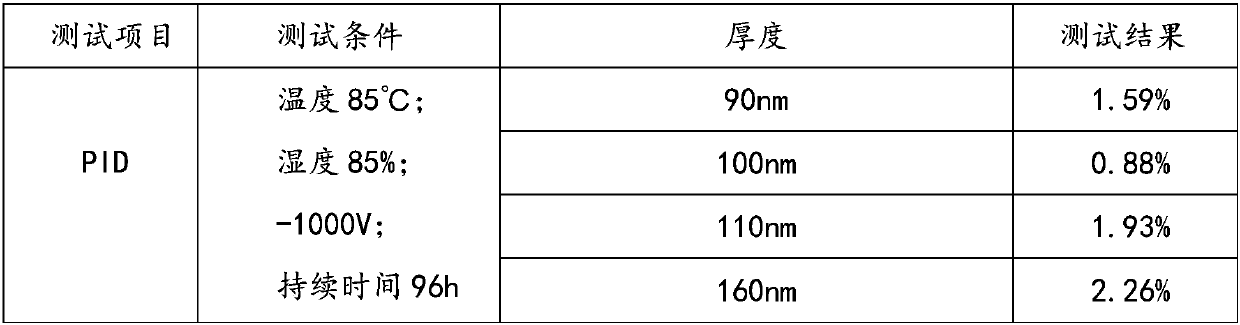

[0032] like figure 1 As shown, the present embodiment provides a PERC battery assembly with high PID resistance and a preparation method thereof, comprising a substrate layer 1, the top surface of the substrate layer 1 is sequentially provided with a diffusion layer 2, a SiOx positive passivation layer 3 and a substrate layer 1 from bottom to top. SixNy positive antireflection passivation protective film layer 4, the bottom surface of substrate layer 1 is provided with SiOx back passivation layer 6, AlOx back passivation film layer 7 and SixNy back antireflection passivation protective film layer 8 sequentially from top to bottom, SixNy positive The thickness of the anti-reflection passivation protective film layer 4 is 75-95nm, and its refractive index is 2.08-2.13. The number of film layers is at least 2 layers, and the refractive index of the nearest layer from the substrate layer 1 is ≥ 2.1, the thickness of the AlOx back passivation film layer 7 is 2-28nm, and the refract...

Embodiment 2

[0047] like Figures 1 to 2 As shown, this embodiment provides a method for preparing a PERC cell assembly with high PID resistance, comprising the following steps:

[0048] S1: According to the tubular PECVD process, the diffusion layer 2 and the SiOx positive passivation layer 3 are sequentially prepared on the top surface of the substrate layer 1, and the SiOx back passivation layer 6 is prepared on the bottom surface of the substrate layer 1;

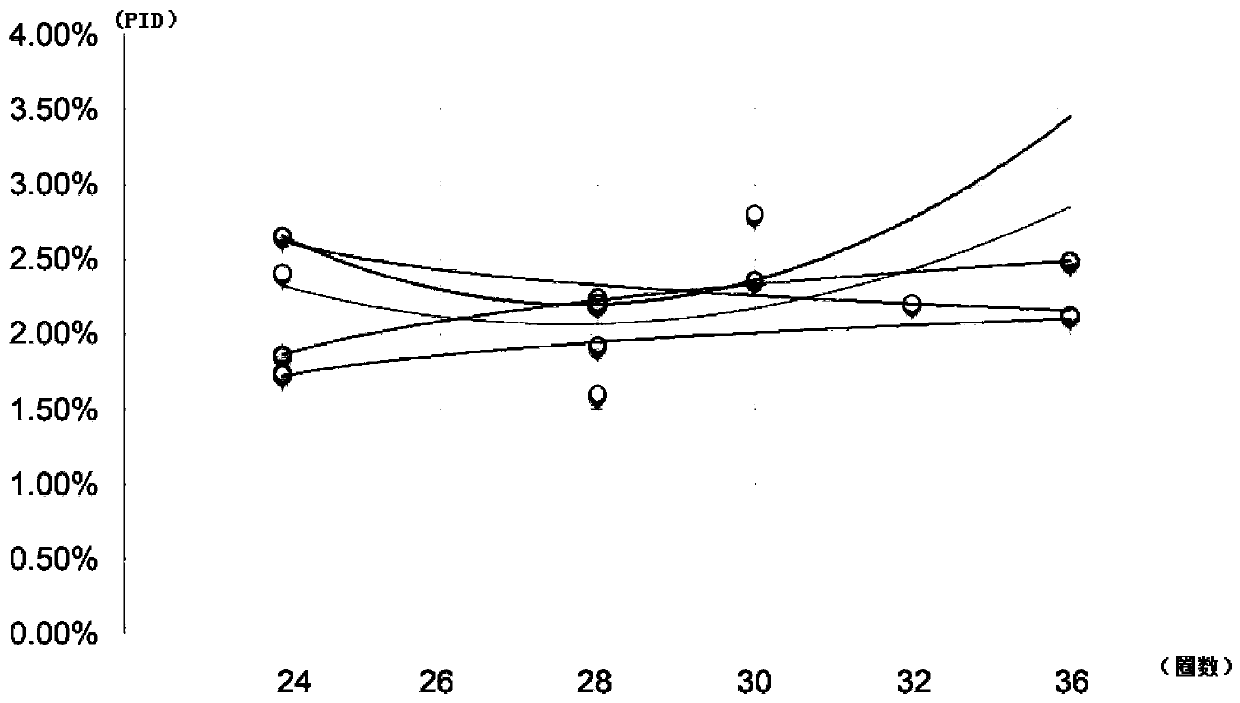

[0049] S2: Then, the AlOx rear passivation layer 7 is deposited on the bottom surface of the SiOx rear passivation layer 6 by ALD process, and the number of deposition circles is 24-36 circles;

[0050] S3: Then coating the top surface of the SiOx positive passivation layer 3 to form a SixNy positive anti-reflection passivation protective film layer 4, and annealing, the annealing time is 17-44min, and the annealing temperature is 380-480°C;

[0051] S4: Then coating the bottom surface of the AlOx back passivation layer 7 to form a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com