A method for detecting the reliability of photovoltaic modules

A detection method and technology of photovoltaic modules, which are applied in the monitoring of photovoltaic systems, photovoltaic modules, photovoltaic power generation, etc., can solve the problems of lack of detection, reduced electrical conductivity and bonding performance, weak reliability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

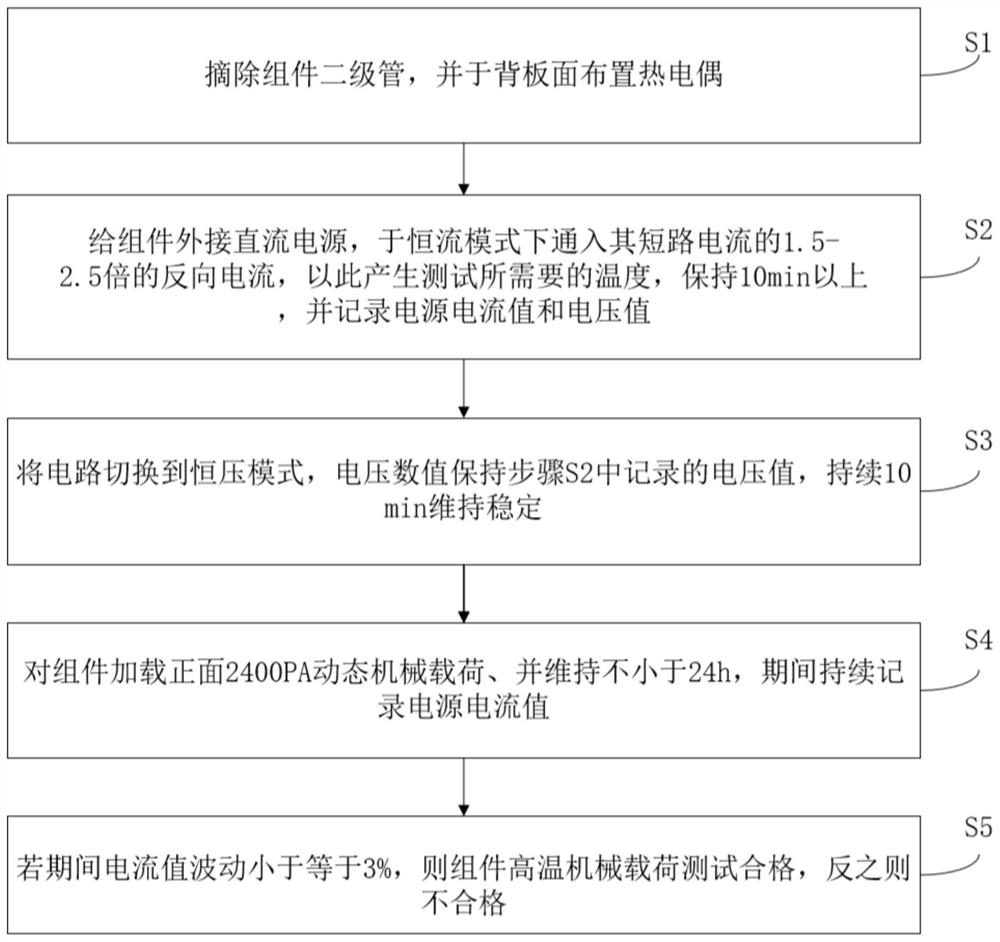

[0036] A method for detecting the reliability of a photovoltaic module, comprising the following steps:

[0037] S1. Remove the diode of the component to ensure that the bypass diode of the component will not be broken down and short-circuited when the component is powered on, and a thermocouple is arranged on the backplane to detect the temperature of the component;

[0038] S2. Connect an external DC power supply to the component, and pass in a reverse current of 1.5 times its short-circuit current in constant current mode, and connect the positive pole of the power supply to the positive pole of the component to realize the reverse current supply, and keep it for 10 minutes. When the current is high, it will generate heat to generate the high temperature required for the test. At the same time, the temperature of the component is detected and maintained at 130 degrees Celsius. The temperature of the component is controlled by adjusting the input current, and the current valu...

Embodiment 2

[0043] A method for detecting the reliability of a photovoltaic module, comprising the following steps:

[0044] S1. Remove the diode of the component to ensure that the bypass diode of the component will not be broken down and short-circuited when the component is powered on, and a thermocouple is arranged on the backplane to detect the temperature of the component;

[0045] S2. Connect an external DC power supply to the component, and pass in a reverse current 2.5 times its short-circuit current in constant current mode. Connect the positive pole of the power supply to the positive pole of the component to realize the reverse current supply, and keep it for 30 minutes. When the current is high, it will generate heat to generate the high temperature required for the test. At the same time, the temperature of the component is detected and maintained at 150 degrees Celsius. The temperature of the component is controlled by adjusting the incoming current, and the current value an...

Embodiment 3

[0050] A method for detecting the reliability of a photovoltaic module, comprising the following steps:

[0051] S1. Remove the diode of the component to ensure that the bypass diode of the component will not be broken down and short-circuited when the component is powered on, and a thermocouple is arranged on the backplane to detect the temperature of the component;

[0052] S2. Connect an external DC power supply to the component, pass in a reverse current 2.0 times its short-circuit current in constant current mode, connect the positive pole of the power supply to the positive pole of the component to realize the reverse current supply, and keep it for 40 minutes. It will generate heat when the current is high, so as to generate the high temperature required for the test. At the same time, the temperature of the component is detected and maintained at 145 degrees Celsius. The temperature of the component is controlled by adjusting the input current, and the current value and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com