Electromagnetic induction heating control method and electromagnetic heating device

A technology of heating equipment and control circuit, applied in the field of electromagnetic induction heating control and electromagnetic heating equipment, can solve the problems of large noise, large working noise, large instantaneous power fluctuation, etc., to expand the power range, reduce operating noise, start low current effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

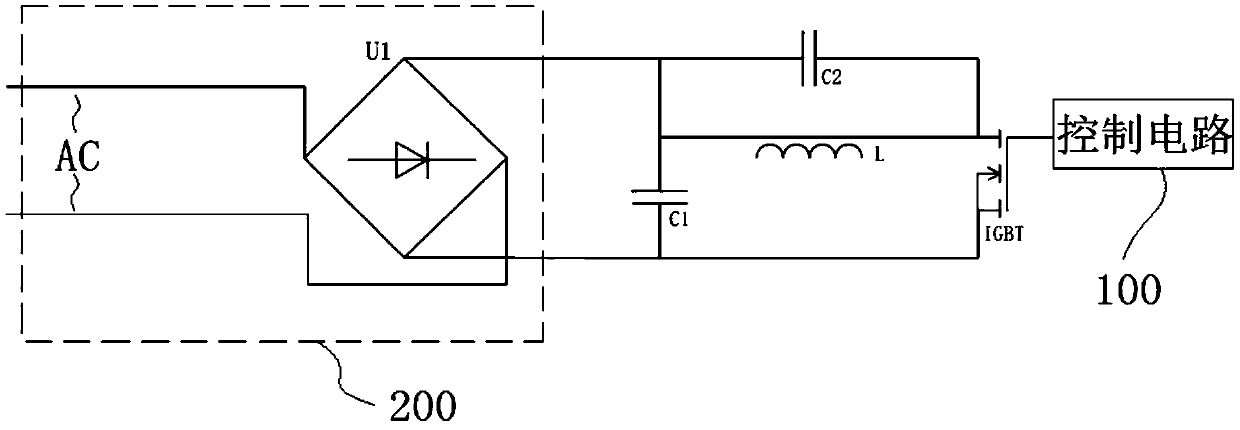

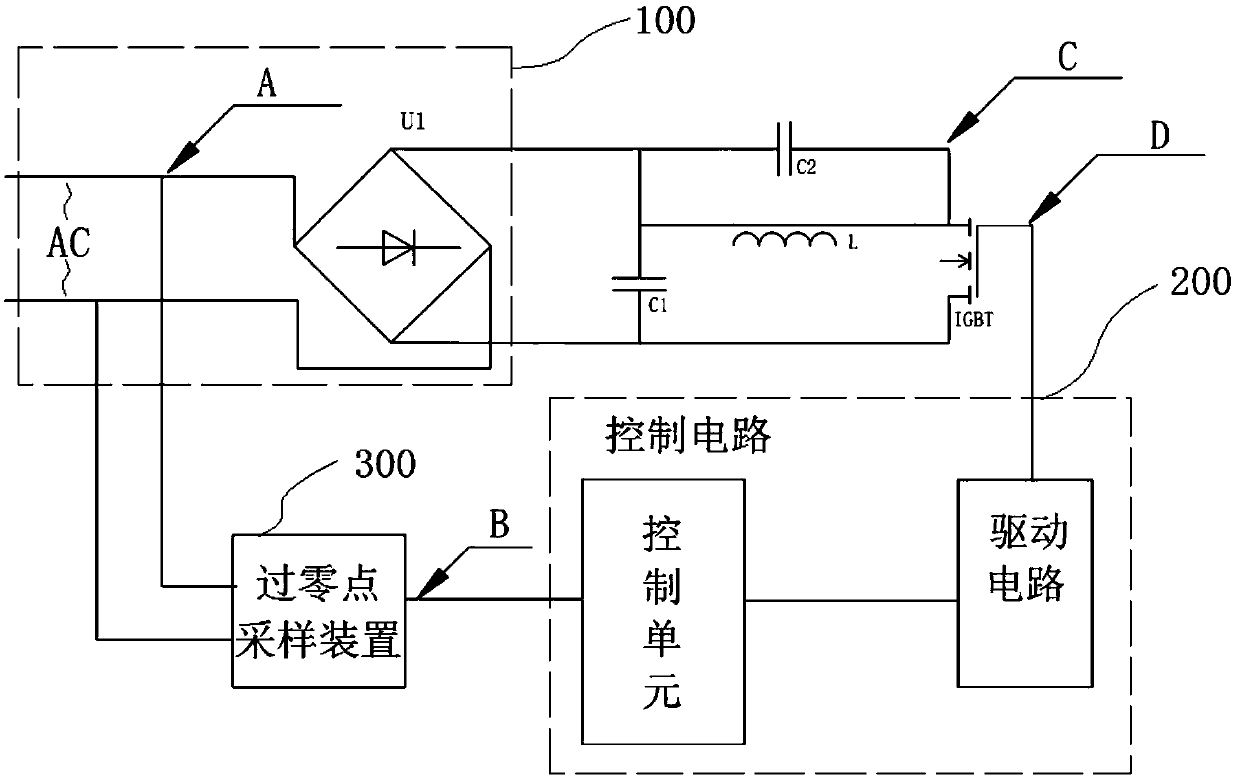

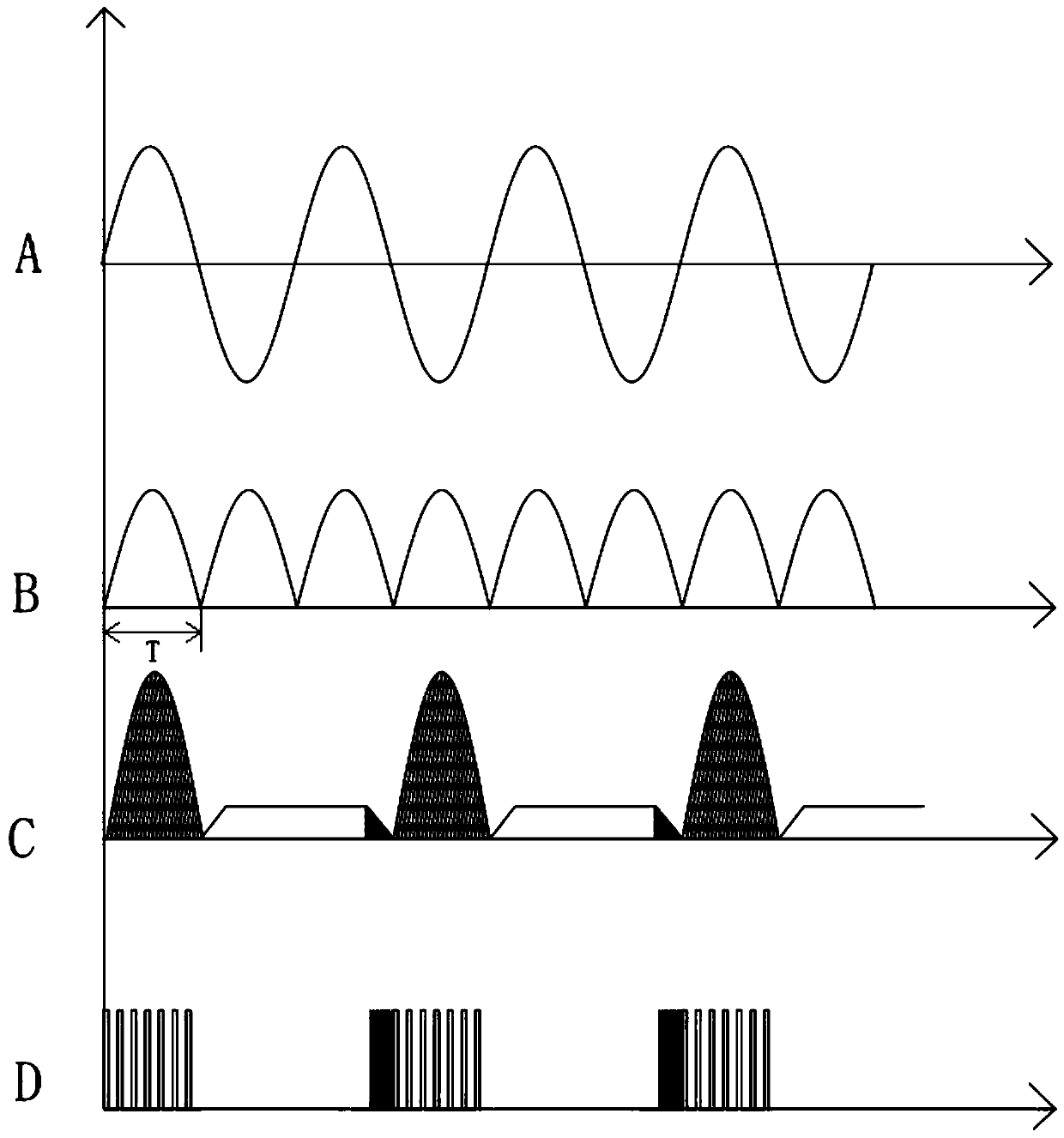

[0044] The technical problem to be solved by the present invention is: the existing electromagnetic heating equipment with a power of less than 800W will be realized by high-power intermittent heating. Since the noise is large when starting and stopping, the switching frequency cannot be too high, so the instantaneous power fluctuates greatly, which affects cooking. Effect; if low-power continuous heating is required, it is generally necessary to change the circuit topology, drive voltage, resonance parameters, etc., but this will lead to increased costs, complicated circuits, short life of key components, and increased operating noise And other issues. The technical idea proposed by the present invention is to detect the zero-crossing point of the power supply voltage, and input a driving voltage with a small pulse width to the gate of the insulated-gate bipolar transistor IGBT before the zero-crossing point, so as to drive the integrated circuit of the IGBT The electrode vol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com