Textile disinfection device for textiles

A technology for disinfection devices and textiles, which is used in disinfection, water supply devices, drying gas layout, etc., can solve the problems of insufficient disinfection, short movement paths, shortening disinfection time, etc., and achieve the effects of sufficient disinfection, quality assurance, and prolonged disinfection time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

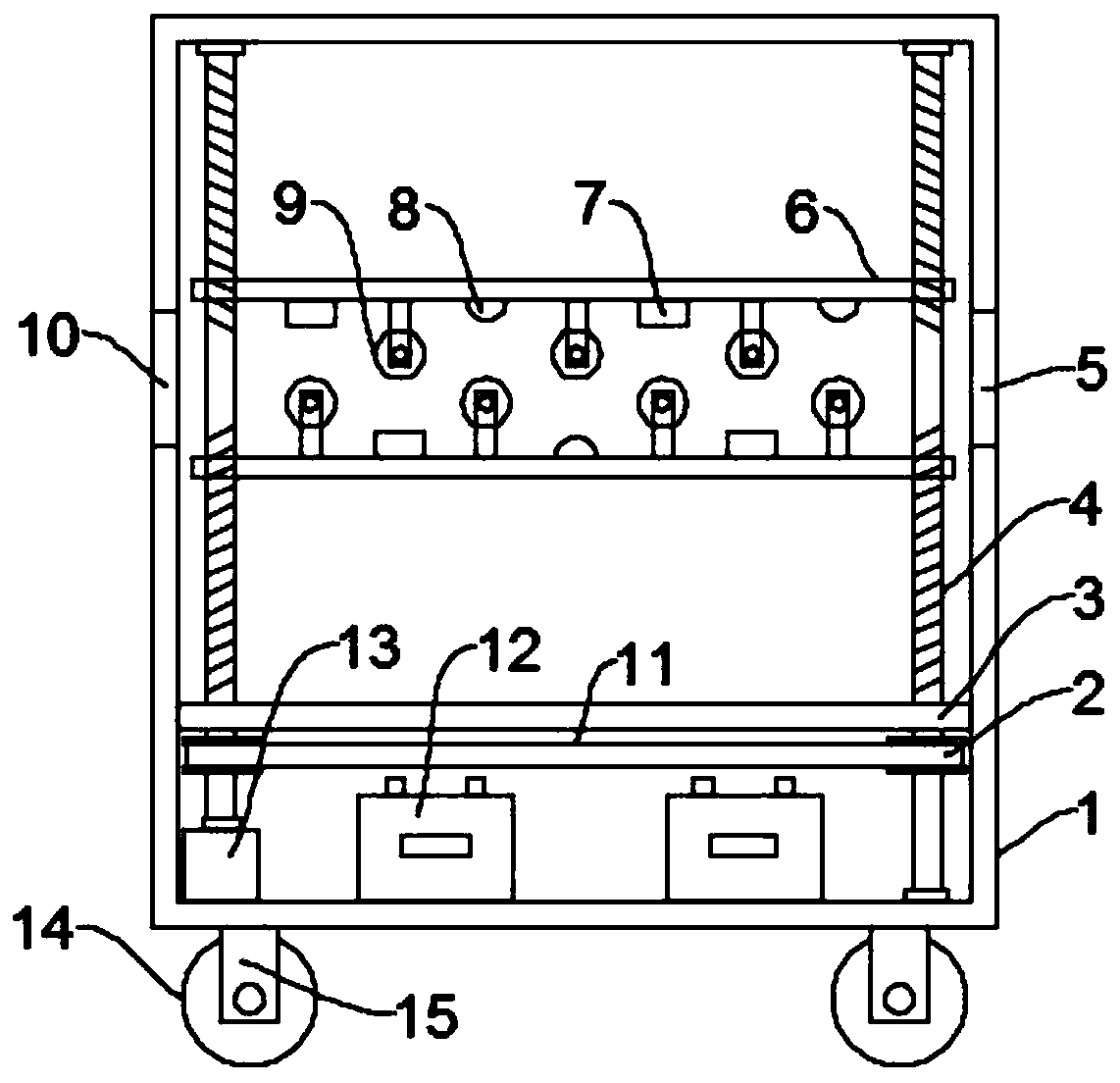

[0026] see figure 1 , in an embodiment of the present invention, a textile disinfection device for textiles, comprising a disinfection box 1 and a disinfection assembly, the disinfection assembly is installed in the disinfection box 1, and the bottom of the disinfection box 1 is evenly and symmetrically equipped with support legs 15, and the support legs 15 bottom end is equipped with roller 14, and described roller 14 is self-locking type roller, and the movement of convenience device, described sterilizing case 1 left and right sides are symmetrically provided with feed inlet 10 and discharge port 5, and sterilizing case 1 front side wall A box door is installed on it, and the box door is preferably connected with the disinfection box 1 through hinges and buckles. The disinfection assembly includes a mounting plate 6, an ultraviolet germicidal lamp 8 and an ozone generator 7. There are two mounting plates 6 and they are installed separately. On the upper and lower sides of t...

Embodiment 2

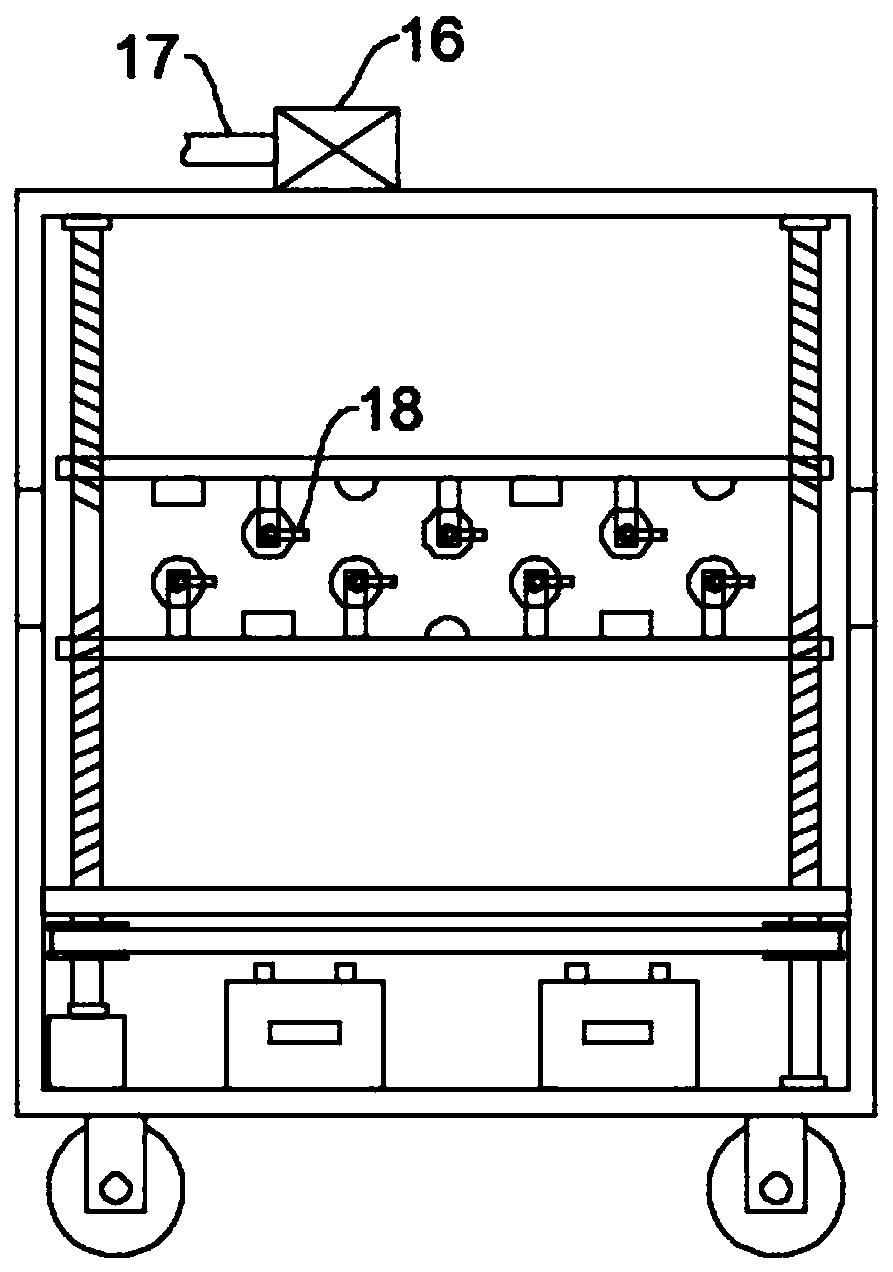

[0028] see figure 2 , in an embodiment of the present invention, a textile disinfection device for textiles, comprising a disinfection box 1 and a disinfection assembly, the disinfection assembly is installed in the disinfection box 1, and the bottom of the disinfection box 1 is evenly and symmetrically equipped with support legs 15, and the support legs 15 bottom end is equipped with roller 14, and described roller 14 is self-locking type roller, and the movement of convenience device, described sterilizing case 1 left and right sides are symmetrically provided with feed inlet 10 and discharge port 5, and sterilizing case 1 front side wall A box door is installed on it, and the box door is preferably connected with the disinfection box 1 through hinges and buckles. The disinfection assembly includes a mounting plate 6, an ultraviolet germicidal lamp 8 and an ozone generator 7. There are two mounting plates 6 and they are installed separately. On the upper and lower sides of ...

Embodiment 3

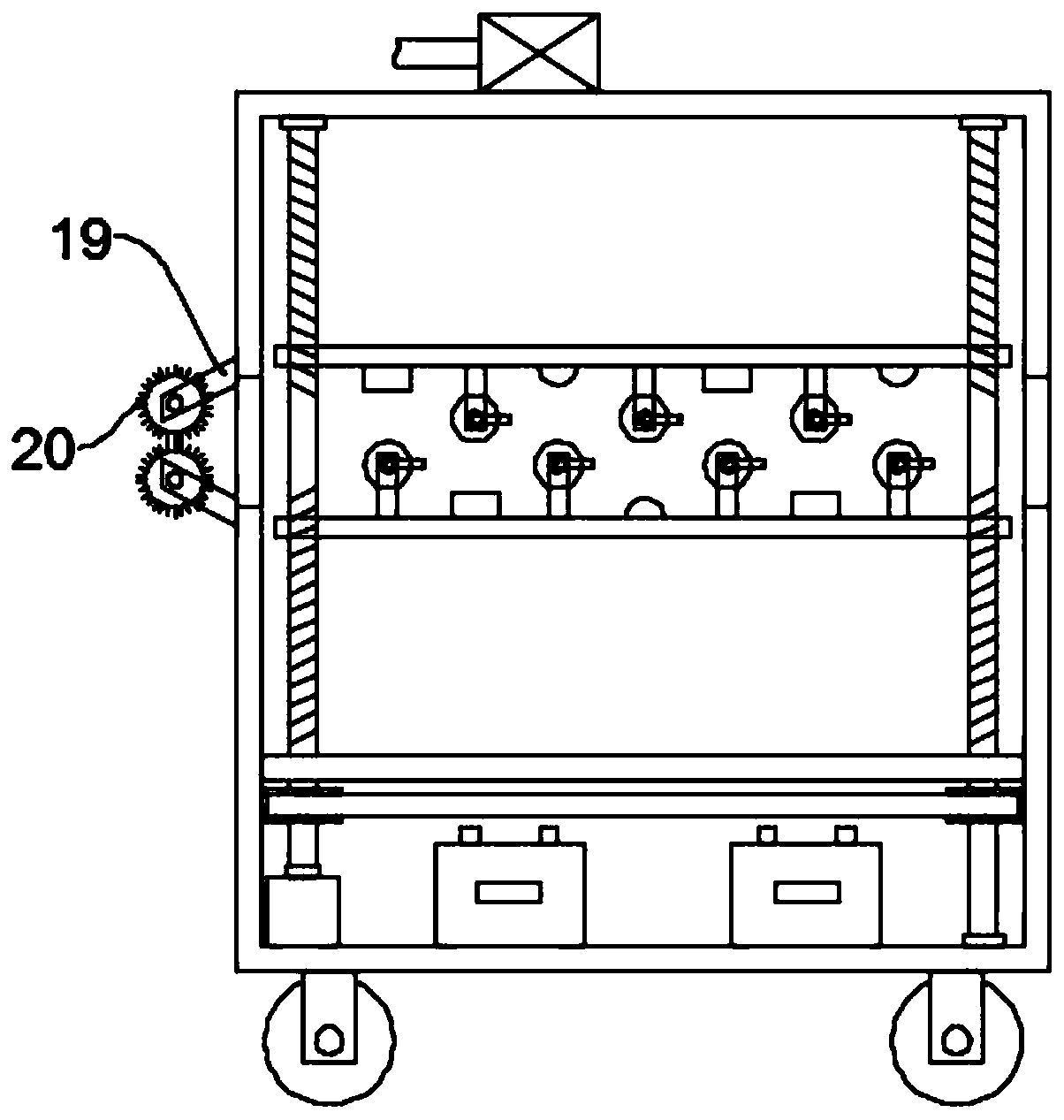

[0031] see image 3 , in an embodiment of the present invention, a textile disinfection device for textiles, comprising a disinfection box 1 and a disinfection assembly, the disinfection assembly is installed in the disinfection box 1, and the bottom of the disinfection box 1 is evenly and symmetrically equipped with support legs 15, and the support legs 15 bottom end is equipped with roller 14, and described roller 14 is self-locking type roller, and the movement of convenience device, described sterilizing case 1 left and right sides are symmetrically provided with feed inlet 10 and discharge port 5, and sterilizing case 1 front side wall A box door is installed on it, and the box door is preferably connected with the disinfection box 1 through hinges and buckles. The disinfection assembly includes a mounting plate 6, an ultraviolet germicidal lamp 8 and an ozone generator 7. There are two mounting plates 6 and they are installed separately. On the upper and lower sides of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com