A direct contact fluid ice slurry generator and its preparation method

A liquid ice and contact technology, which is applied in ice making, ice making, lighting and heating equipment, etc., can solve the problems that affect the ice making efficiency, water can not be in direct contact with the refrigerant, etc., to improve the contact area and contact Time, improve the efficiency of ice making, improve the effect of heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

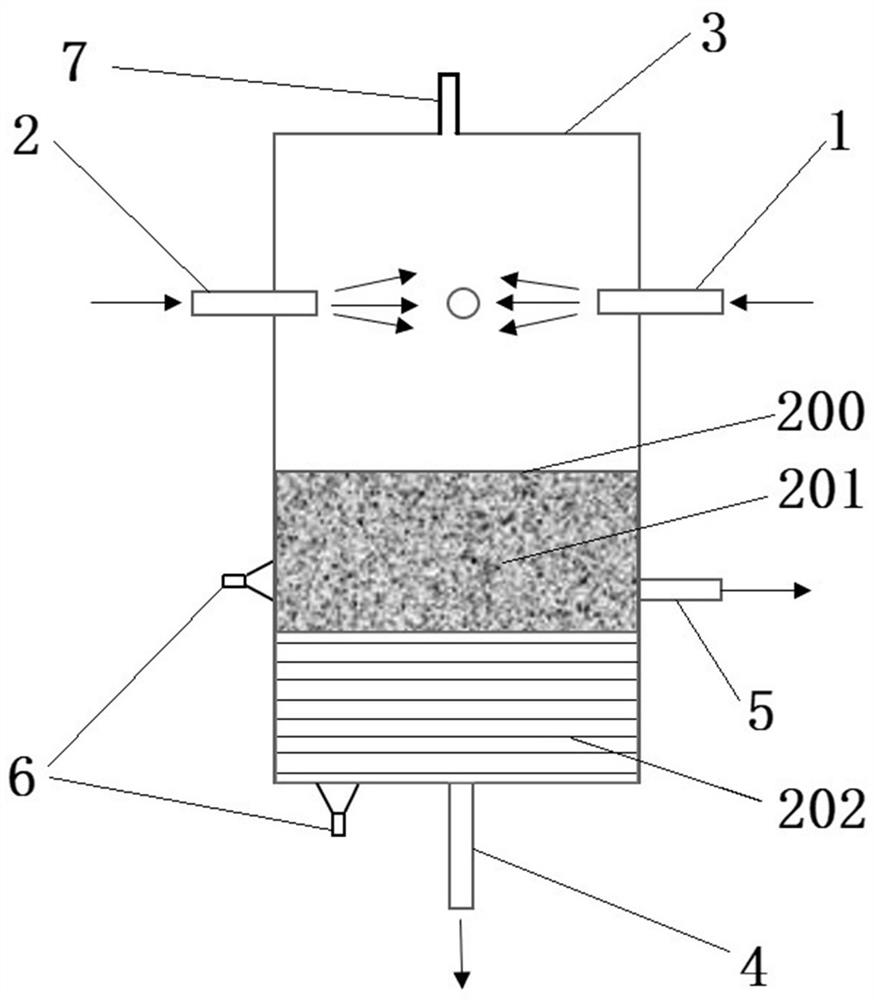

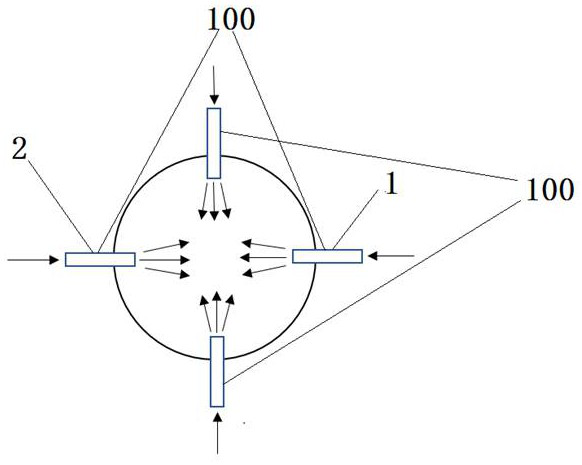

[0038]The structure of the preparation device in this embodiment is as figure 1 and figure 2 As shown, the production device includes an ice slurry production cylinder 3, the bottom of the ice slurry production cylinder 3 is provided with a lower fluid outlet 4 and an ice slurry outlet 5, and the brine and ice-making working medium are directly contacted in the ice slurry production cylinder. When producing ice slurry, the ice slurry floats lightly to form the upper ice slurry layer 201, and the rest of the fluids are mixed together to form the lower fluid layer 202 below, and the prepared ice slurry flows out through the ice slurry outlet 5 and enters the corresponding storage bin Among them, the lower layer fluid flows out through the lower layer fluid outlet 4 and is recycled.

[0039] A nozzle group 100 is provided on the circumferential wall of the ice slurry production cylinder 3, and the nozzle group 100 is located above the spray outlet 5, and the nozzle groups here ...

Embodiment 2

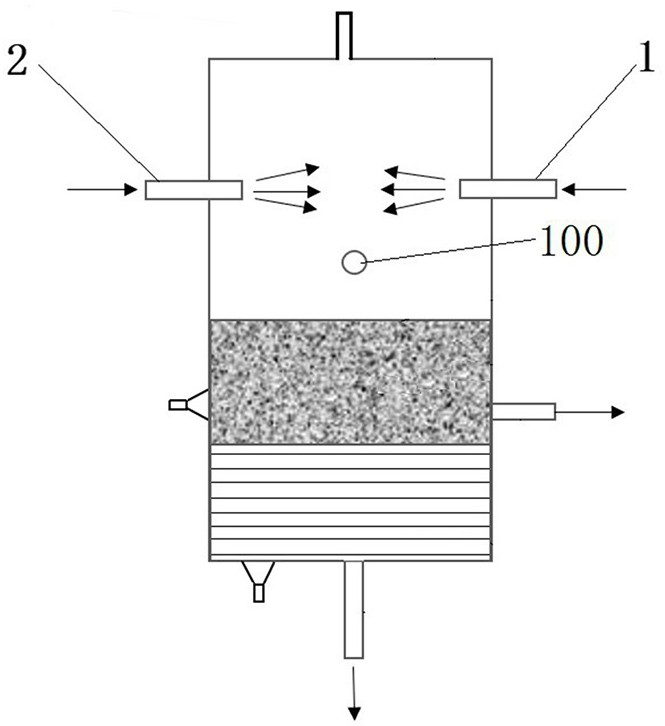

[0050] The structure of the direct contact type fluid ice slurry maker in embodiment 2 is as follows image 3 As shown, the structure of the fluid ice slurry extractor is basically the same as that of the ice slurry extractor in Example 1, the only difference being that in the ice slurry extractor 3 in Example 2, the nozzle group is along the ice slurry Two layers are arranged at intervals in the axial direction of the preparation cylinder 3 , and each layer is provided with a nozzle group, and each nozzle group includes a brine nozzle 1 and an ice-making working medium nozzle 2 . Moreover, in this embodiment, the two-layer nozzle groups are distributed in a staggered manner in the circumferential direction of the ice slurry production cylinder.

[0051] In other embodiments, the nozzle groups may be distributed in more than three layers at intervals along the axial direction of the ice slurry production cylinder. Of course, the brine nozzles and the ice-making working medium...

Embodiment 3

[0053] The structure of the direct contact type fluid ice slurry maker in embodiment 3 is as follows Figure 4 and Figure 5 As shown, the structure of the fluid ice slurry extractor is basically the same as that of the ice slurry extractor in Embodiment 1, the only difference being that only one group of nozzle groups is provided on the ice slurry extractor cylinder 3 in Embodiment 3 100. The nozzle group 100 includes a refrigerant nozzle 1 and an ice-making working medium nozzle 2, and the two nozzles need only be arranged facing each other.

[0054] In the above embodiments, the brine nozzle can be selected from a gaseous refrigerant or a liquid refrigerant according to actual needs, so as to meet the ice slurry preparation requirements under different conditions.

[0055] In the above-mentioned embodiments, when the direct-contact fluid ice slurry generator is in use, it needs to be connected with corresponding brine input pipelines, ice-making working medium input pipeli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com