Pneumatic transformer fault oil drainage system

A technology for transformer failure and pneumatic oil discharge, which is applied in the direction of transformer/inductor cooling, fluid pressure actuators, servo motor components, etc. problems, achieving the effect of no maintenance, improved system reliability, and quick start-up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

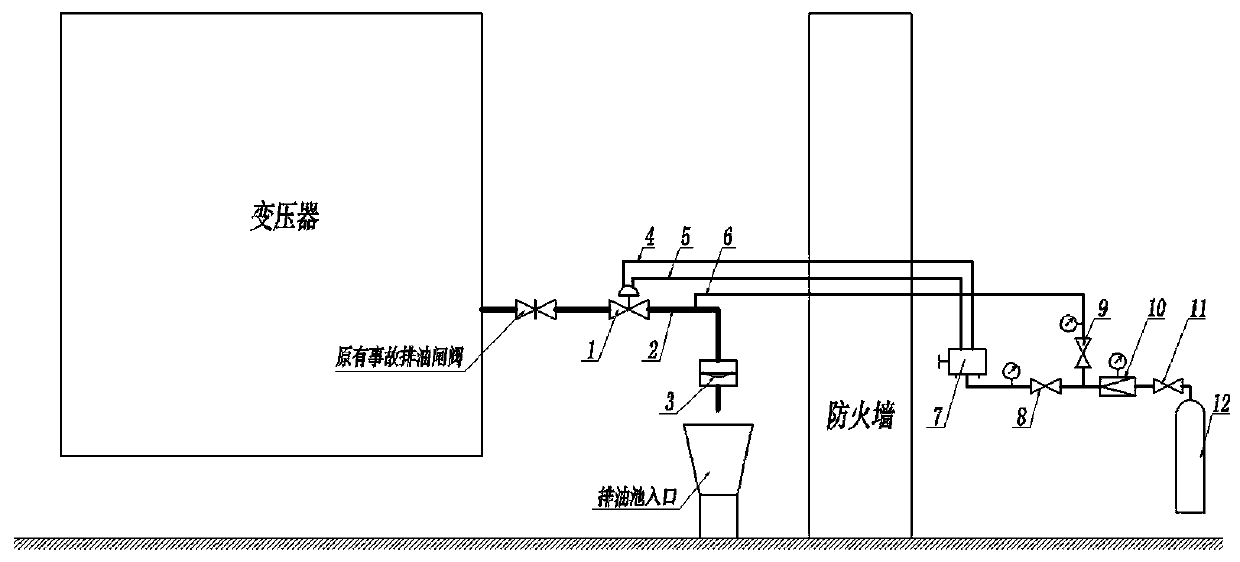

Embodiment 1

[0034] Such as figure 1 As shown, the oil outlet of the original accident oil drain gate valve of the transformer is connected to the pneumatic oil drain valve 1, the outlet of the pneumatic oil valve 1 is connected to the component pipeline 2 and the bursting disc 3, and the outlet of the bursting disc 3 enters the underground oil discharge through the pipeline Pool; set the air inlet on the component pipeline 2 and connect the bursting disc opening control pipeline 6 to the pneumatic control system; the control part of the pneumatic oil drain valve 1 connects the oil discharge opening control pipeline 4 and the oil discharge closing control pipeline 5 to Pneumatic control system. The pneumatic control system consists of a bursting disc opening control valve 9, an oil discharge control valve 8, a reversing valve 7, a pressure reducing valve 10, an air source main valve 11, an air source 12, pipelines and pressure gauges and is installed in the pneumatic control cabinet . The ...

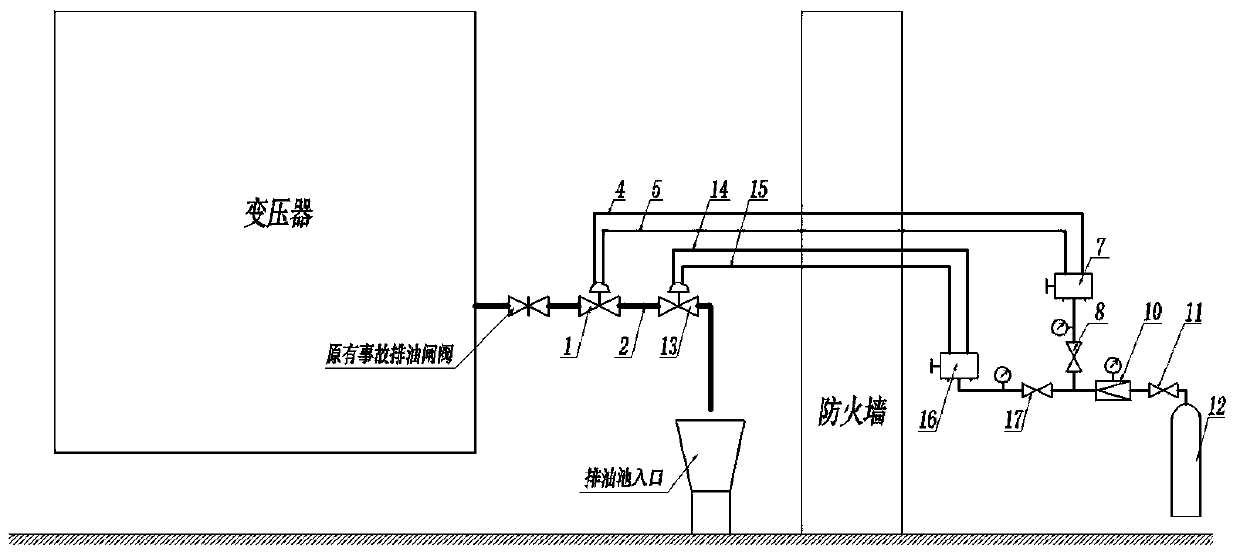

Embodiment 2

[0040] Such as figure 2 As shown, the outlet of the original accident drain gate valve of the transformer is connected with two series-connected pneumatic drain valve 1 and pneumatic sealing valve 13. The latter one can have the same specifications as the previous one, and its function is to seal the second time. The outlet is connected to the inlet of the underground oil drain tank; the control parts of the pneumatic oil drain valve 1 and the pneumatic sealing valve 13 have pipelines connected to the pneumatic control cabinet, and the valve is opened by pneumatic drive. After installation, the pneumatic oil drain valve 1 and the pneumatic sealing valve 13 are both in the closed state, and the sealing reversing valve 16 leads to the sealing opening control line 14; after vacuuming or filling and exhausting the front line of the pneumatic oil drain valve (1) , Open the original accident oil drain gate valve of the transformer, the transformer insulating oil flows in and is seale...

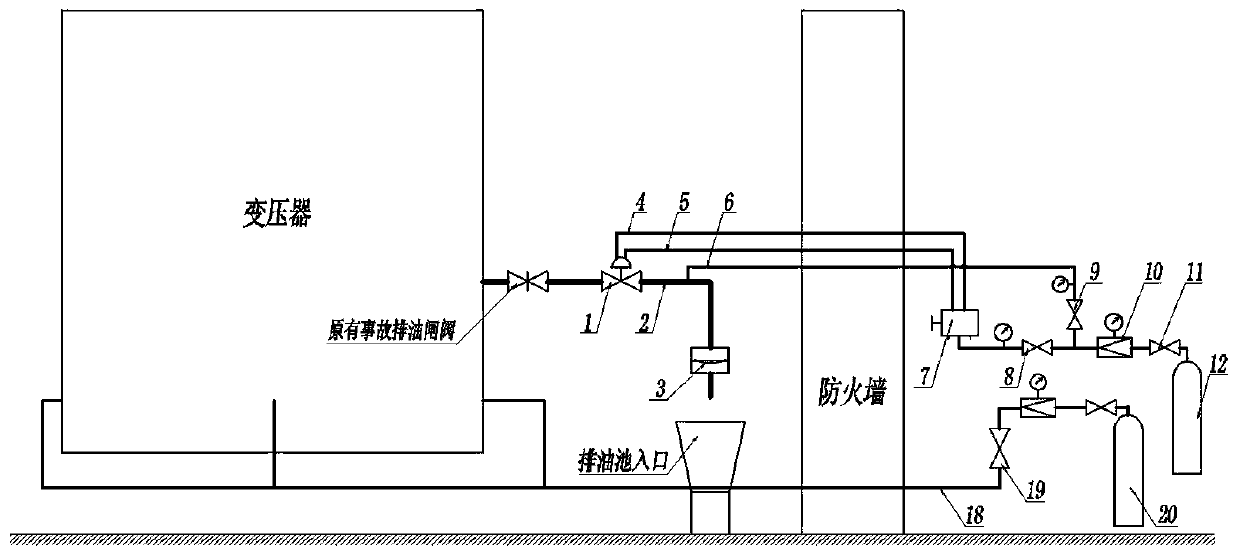

Embodiment 3

[0043] Such as image 3 As shown, on the basis of the technical solutions of the first or second embodiment, a flame-retardant gas pipeline 18 communicating with the inside of the oil tank is evenly distributed around the transformer, and the flame-retardant gas pipeline is connected to a flame-retardant gas cylinder 20 through a valve 19 and a pressure reducing valve. , The flame retardant gas can be nitrogen, carbon dioxide or other inert gases. When the transformer has a serious fault and needs to drain oil, when the pneumatic oil drain device is turned on, the flame-retardant gas pipeline valve 19 is opened to realize the flame-retardant gas enters the transformer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com