Method of producing edible pet chew product and product produced thereby

A product, pet technology, applied in the field of pet chews, can solve the problems of surface texture, shape and size changes, and achieve the effect of no surface defects and high dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

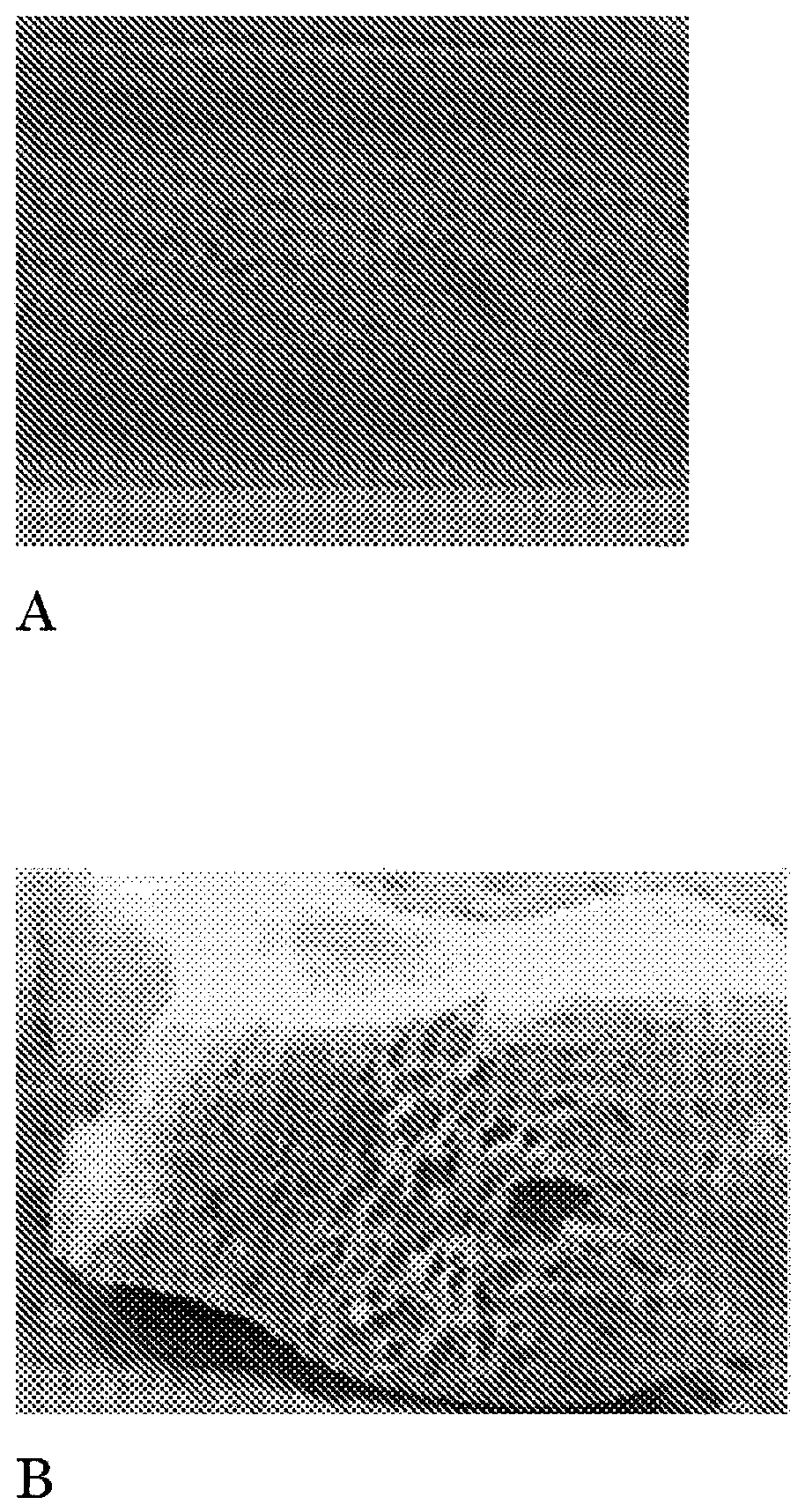

[0142] Example 1. Foamy skin-core product according to the invention versus non-stratified bubbles of the prior art microwave process foam product

[0143] figure 1 (A) is shown and by using according to especially as in US 6,180,161 figure 1 Compared with the porous product prepared by the microwave heating step of the starch composition prepared by the method in (B), as listed in Example 2 (below), the cross-section of the partially porous injection molded product produced according to the present invention Details.

Embodiment 2

[0144] Example 2. Foamed skin-core product molded from one material

[0145] Injection molding tests were performed using a typical (Paragon) material composition A. To this composition was added 1% of PlastronFoam F01-17 from Plastron SAS, France by dry blending.

[0146] Injection molding takes place via an injection unit of a sandwich module. The temperature distribution along the barrel of the injection molding machine is: feed zone: 50°C; zone 2: 50°C; zone 3: 60°C; zone 4: 80°C; zone 5: 100°C; zone 6: 120°C; zone 7 : 130°C; Zone 8: 130°C. The temperature of the sandwich hot runner module is 130°C. The temperature of the fixed mold half (including the cold runner) is 35°C, and the temperature of the movable mold half is 25°C. The anti-punch distance (applied during the first part of the cooling phase) is a maximum of 2 mm. The total cycle time is about 50 seconds.

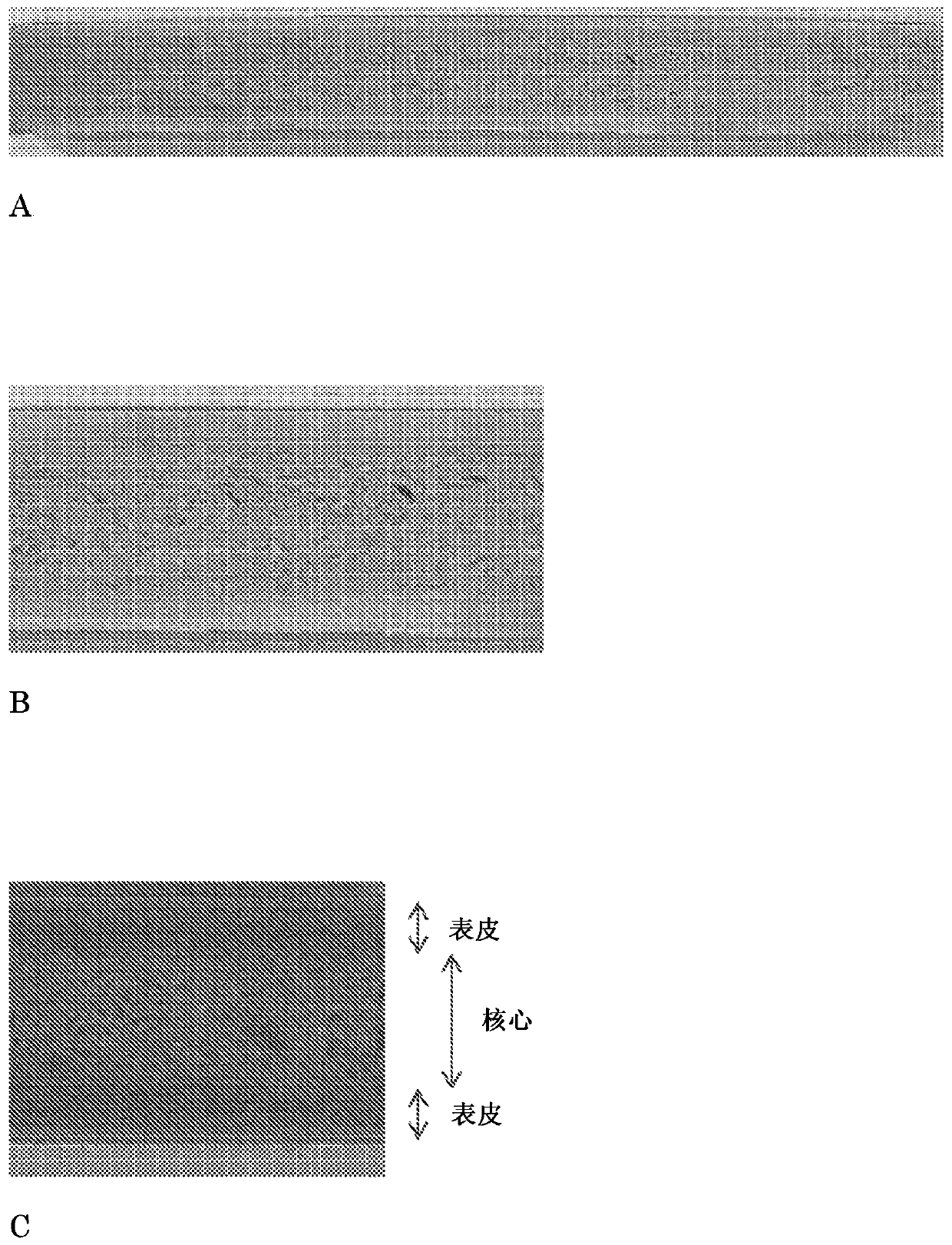

[0147] The resulting product may be characterized as a skin-core product, wherein the skin (thickne...

Embodiment 3

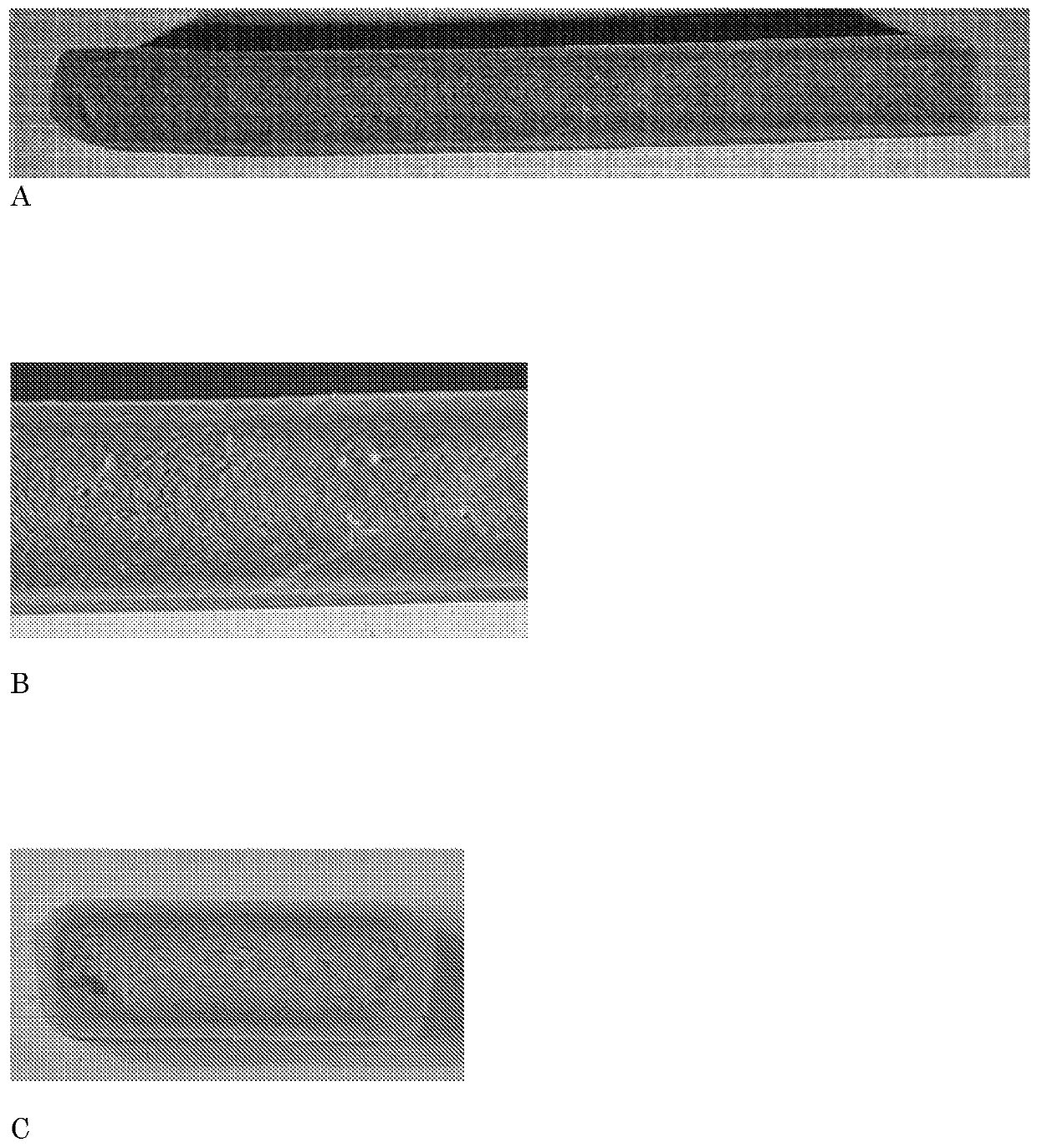

[0150] Example 3. Sandwich molding using 2 different materials to create a foamy skin-core product

[0151] Sandwich injection molding tests were performed using typical material composition A (skin material) and typical material composition B (core material). 1% of PlastronFoam F01-17 from Plastron SAS, France was added to the core material by dry blending.

[0152]The injection molding takes place via the two injection units of the sandwich module. The temperature distribution along the two barrels of the injection molding machine is: feed zone: 50°C; zone 2: 50°C; zone 3: 60°C; zone 4: 80°C; zone 5: 100°C; zone 6: 120°C; Zone 7: 130°C; Zone 8: 130°C. The temperature of the sandwich hot runner module is 130°C. The temperature of the fixed mold half (including the cold runner) is 35°C, and the temperature of the movable mold half is 25°C.

[0153] The first composition A is injected into the mold. After 40% of the total volume had been injected into the mold, the feeds...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com