Assembly production line for three-dimensional cavity fiber structure reinforced cement machine-made board

A technology of fiber structure and reinforced cement, which is applied in the direction of manufacturing tools, ceramic molding machines, ceramic molding workshops, etc., can solve the problems of high worker strength, low production efficiency, and uneven structural stress, and achieve high flexural strength , Reduce labor costs, reduce the effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing.

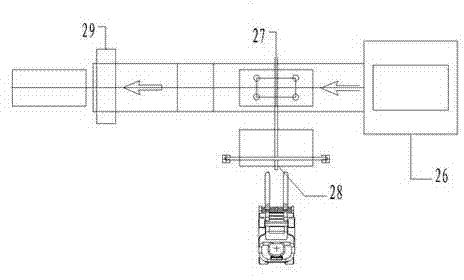

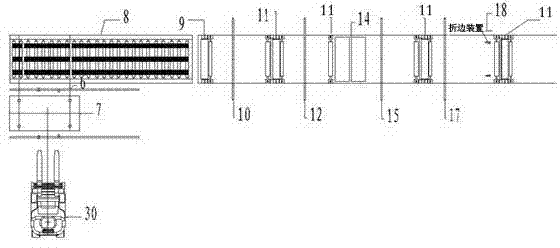

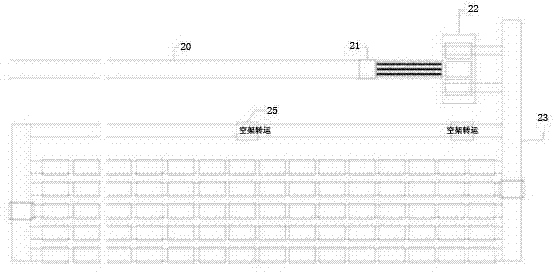

[0024] Such as Figure 1-4 As shown, a three-dimensional cavity fiber structure reinforced cement machine-made slab production line has four storage warehouses for raw materials outdoors, the middle two store cement, and the two sides store sand. The four storage warehouses ensure the large-scale production line. The supply of raw materials during operation and the static stacking of raw materials in the warehouse also avoid the discreteness of product performance and appearance.

[0025] It is equipped with an auxiliary material room and a mixing hopper indoors; the auxiliary material room is used to store auxiliary materials such as water purification, water reducing agent, emulsion, active components, and anti-cracking agent.

[0026] A mixing hopper is set under the raw material storage bin, and the inlet of the mixing hopper is connected to the outdoor raw material st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com