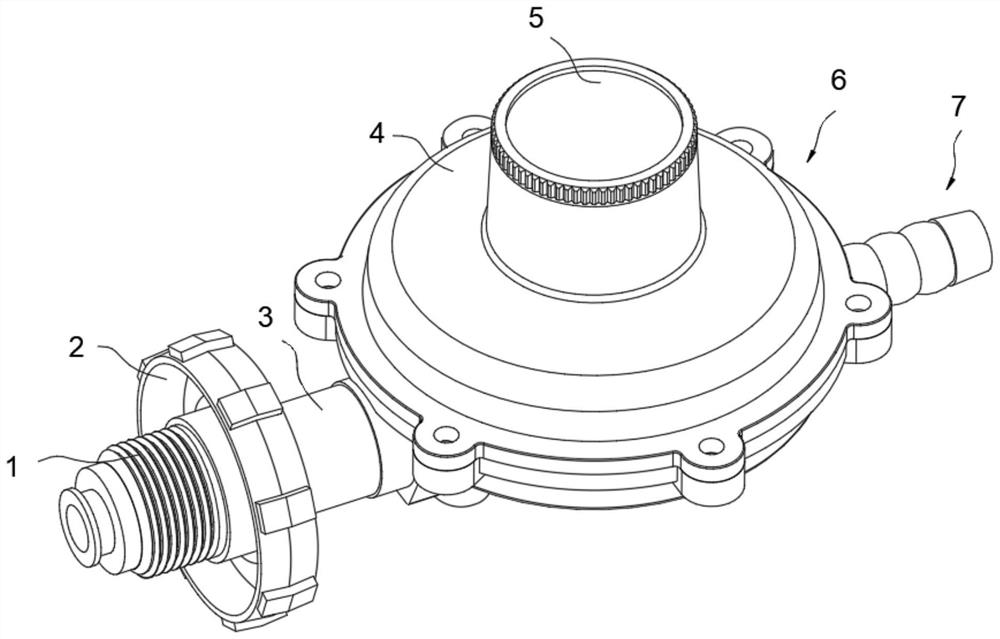

Special valve for liquefied gas

A special valve, liquefied gas technology, applied in valve details, valve device, valve operation/release device, etc., can solve problems such as poor practicability, inability to filter dimethyl ether, bottlenecks in the efficiency of liquefied gas tanks, etc., to prevent The effect of gas leakage and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

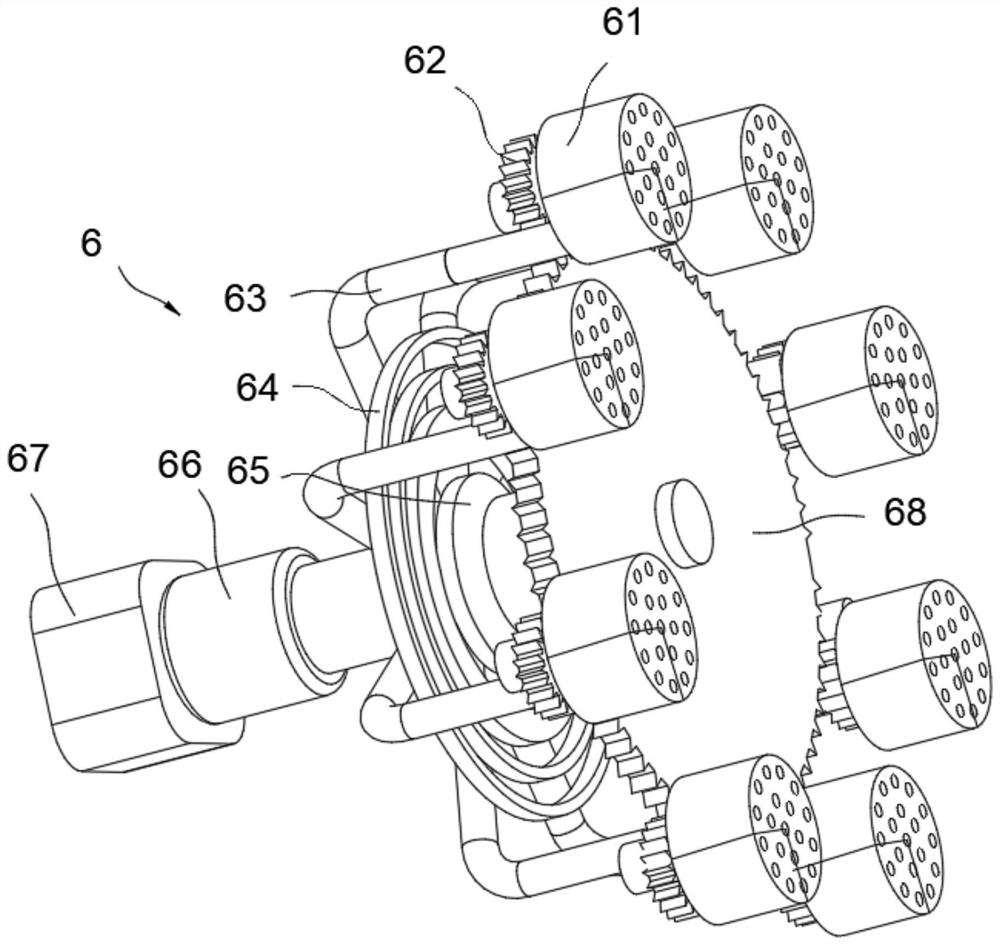

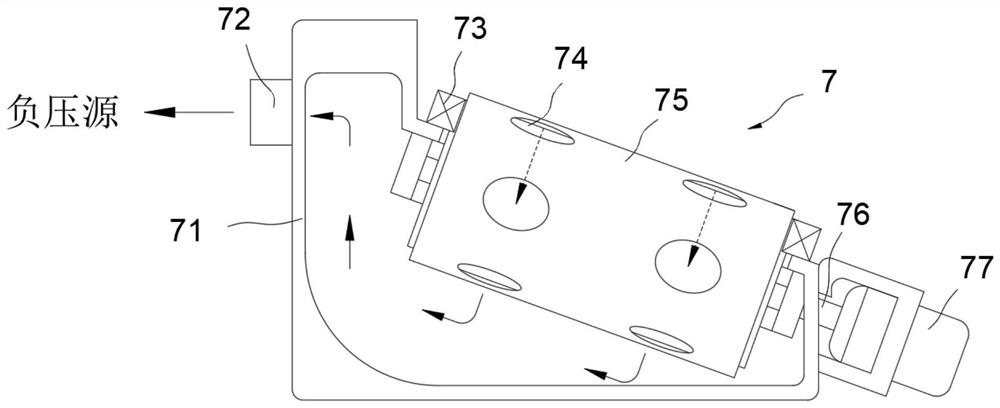

[0034] Embodiment: When using the special air valve, the electromagnet is first energized, and at this time the electromagnet will attract the permanent magnet. After the attraction, the flow path channel of the valve body 4 is opened, and the internal medium can be conducted at this time. , when the electromagnet is powered off, the permanent magnet will block the flow channel of the valve body 4, at this time the channel of the valve body will be reduced to the closed state synchronously, and the degree of opening and closing of the circulation channel will be determined by adjusting the energizing current of the electromagnet, thereby Determine the size of the flow rate, easy to control; when the adsorption device is working, first start to drive the air pump 66, which will bulge the reactant in the reactant box 67 out of the adsorption tube 63, and the adsorption tube 63 is provided with some through holes for The reactant is discharged, so that the fluid around the fixed p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com