Three-flow double-low-rail tundish vehicle and using method thereof

A tundish and rail car technology, used in casting melt containers, metal processing equipment, casting equipment, etc., can solve the problems of high use frequency of tundish, large stress and deformation of tundish, deterioration of tundish, etc., to increase operation. The effect of uniform space and force, reducing stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

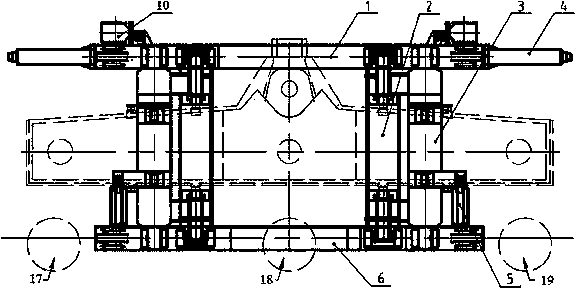

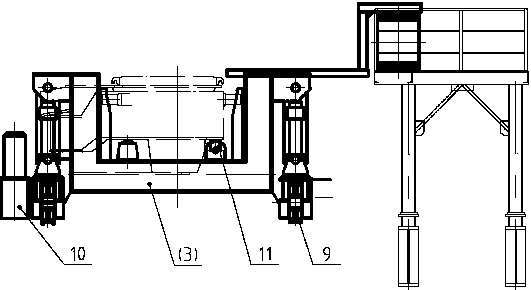

[0037] This embodiment provides a three-stream double low-gauge tundish car, including horizontal low-gauge beams 1 and door-shaped low-gauge beams 6 arranged in parallel and of the same height. The horizontal low-gauge beams 1 are arranged on the continuous casting machine On the outer arc side, the door-shaped low-rail car beam 6 is arranged on the inner arc side of the continuous casting machine. There are three pouring positions on the inner arc side of the continuous casting machine, which are respectively located on both sides of the door-shaped low-rail car beam 6 and centre position;

[0038] The horizontal low-rail car beam 1 and the door-shaped low-rail car beam 6 are connected through the car-beam connecting frame 2 to form a frame body, and the horizontal low-rail car beam 1 is provided with driving wheels 10, and the door-shaped low-rail car The beam 6 is provided with a driven wheel, the horizontal low-rail car beam 1 and the door-shaped low-rail car beam 6 are f...

Embodiment 2

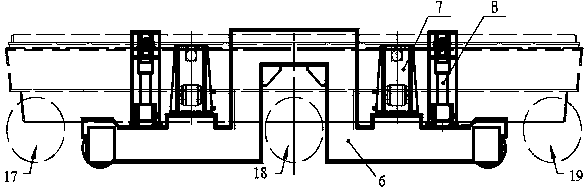

[0042] On the basis of Embodiment 1, this embodiment provides a three-stream double low-rail tundish car, the horizontal low-rail car beam 1 and the door-shaped low-rail car beam 6 are provided with a guide frame 7, and the U-shaped lifting The frame 3 is slidably connected with the guide groove of the guide frame 7 .

[0043] The fixed end of the lifting drive device 8 and the guide frame 7 are fixed on the horizontal low-rail car beam 1 and the door-shaped low-rail car beam 6, and the U-shaped lifting frame 3 is connected with the movable end of the lifting drive device 8. Under the guiding action, the U-shaped lifting frame 3 is moved in the vertical direction to realize the lifting movement.

Embodiment 3

[0045] On the basis of Embodiment 1, this embodiment provides a three-stream double low-gauge tundish car, which also includes a centering device 5 fixed on the cantilever beam on the side of the U-shaped lifting frame 3 .

[0046] The centering device 5 is used to center the nozzle of the tundish in the crystallizer.

[0047] For the three-strand slab continuous casting machine, three pouring positions are required on the inner arc side, and their positions correspond to the position of the tundish nozzle. The pouring positions at both ends are vacated by the two sides of the gate-shaped low-gauge rail car beam 6, and the pouring position in the middle position is to vacate the operation space in the gate-shaped position, so as to achieve the purpose of pouring three-strand slabs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com