Method for preparing large-mixing-amount low-quality mineral admixture recycled cement-based product through microwave curing

A technology of recycled cement and microwave curing, which is applied in the field of building materials to achieve the effect of improving interface bonding performance, improving rapid improvement, and promoting the growth of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

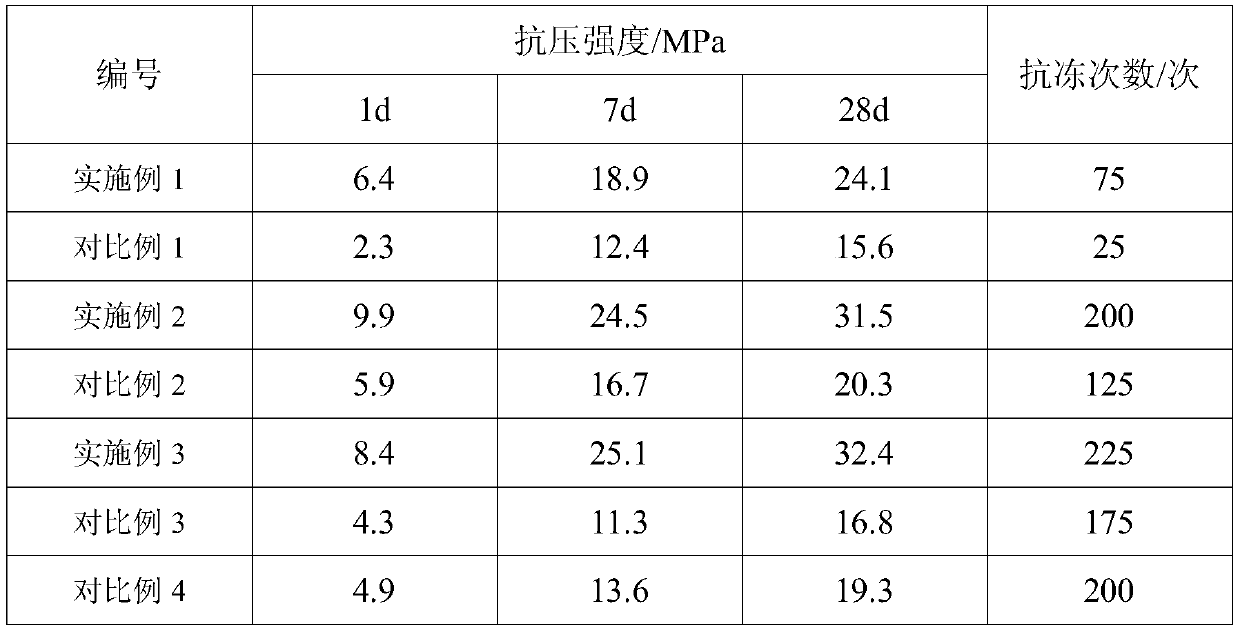

Examples

Embodiment 1

[0030] A method for microwave curing to prepare a large amount of low-quality mineral admixture recycled cement-based products, including:

[0031] (1) Vacuum environment treatment uses alkaline solution to immerse 5-25mm continuously graded regenerated coarse aggregate in a closed container, then evacuates to below 10mbar, keeps for 24h, drains until saturated surface dry, the alkaline solution is hydroxide Sodium aqueous solution (concentration 5M); (2) ultrasonically disperse and mix the mixture of the treated regenerated coarse aggregate, grade III fly ash, water and dispersant, and then evacuate to below 10mbar again for 2h; (3) put Cement, river sand and the above mixture are evenly mixed in a mixer, and molded; (4) microwave curing for 30 minutes under the condition of maximum output power of 30%, and then stop heating for 30 minutes, and cycle twice to obtain the cement-based product.

Embodiment 2

[0033] A method for microwave curing to prepare a large amount of low-quality mineral admixture recycled cement-based products, including:

[0034] (1) Vacuum environment treatment uses alkaline solution to immerse 5-25mm continuously graded regenerated coarse aggregate in a closed container, then vacuumize to below 10mbar, keep for 24h, drain until saturated surface dry, the alkaline solution is sodium carbonate Aqueous solution (concentration 1.5M); (2) ultrasonically disperse and mix the mixture of the treated regenerated coarse aggregate, S75 grade mineral powder, water and dispersant, and then evacuate the mixture below 10mbar again for 2h; (3) put the cement 1. Mix the river sand and the above-mentioned mixture evenly in the mixer, and mold it; (4) microwave curing for 30 minutes under the condition of maximum output power of 30%, and then stop heating for 30 minutes, and cycle twice to obtain the cement-based product.

Embodiment 3

[0036] A method for microwave curing to prepare a large amount of low-quality mineral admixture recycled cement-based products, including:

[0037] (1) Vacuum environment treatment uses alkaline solution to immerse 5-25mm continuously graded regenerated coarse aggregate in a closed container, then vacuumize to below 10mbar, keep for 24h, drain until saturated surface dry, the alkaline solution is silicic acid Potassium aqueous solution (modulus 2.0, concentration 15%); (2) ultrasonically disperse and mix the mixture of the treated regenerated coarse aggregate, low-quality metakaolin, water and dispersant, and then vacuum again to below 10mbar for 2h; (3) Mix cement, river sand and the above-mentioned mixture in the mixer evenly, and mold it; (4) Under the condition of maximum output power of 30%, stop heating for 30 minutes after microwave curing for 30 minutes, and circulate twice to obtain the described Cement based products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com