Method for preparing liquid alkali-free accelerator through ring opening of cyclic amide monomer

A technology of cyclic amide and quick-setting agent, which is applied in the field of liquid alkali-free quick-setting agent for cement concrete, to achieve the effect of reducing preparation cost, high early strength and improving early performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

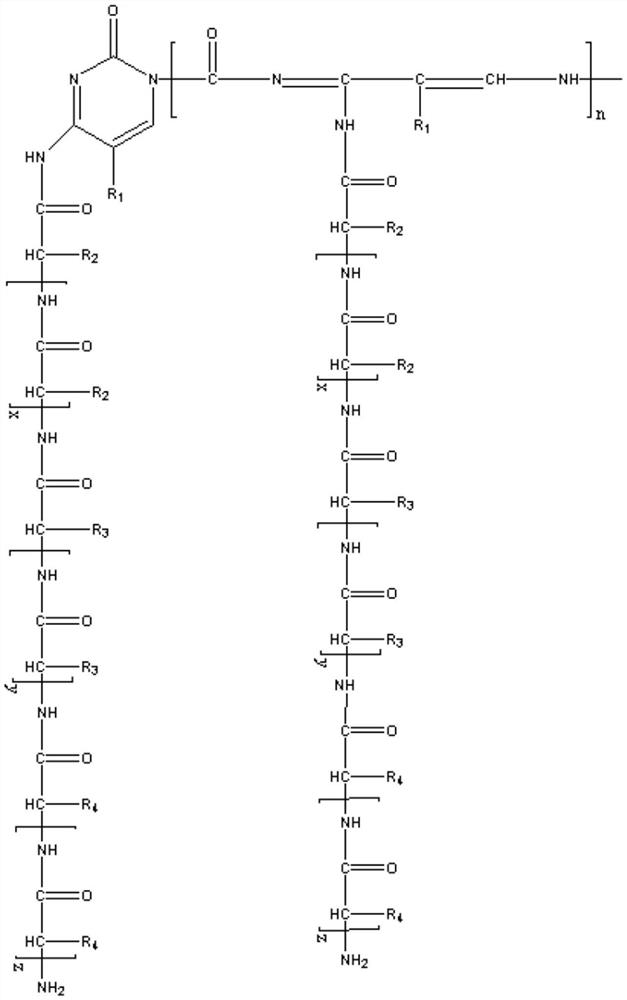

Method used

Image

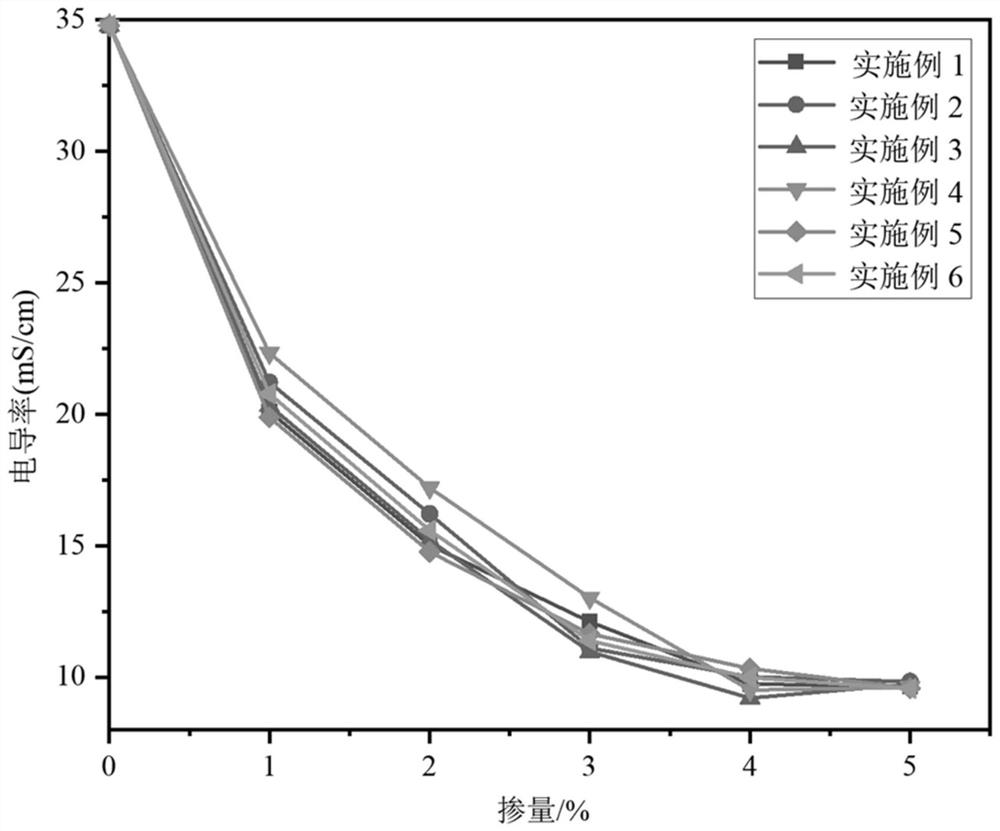

Examples

Embodiment 1

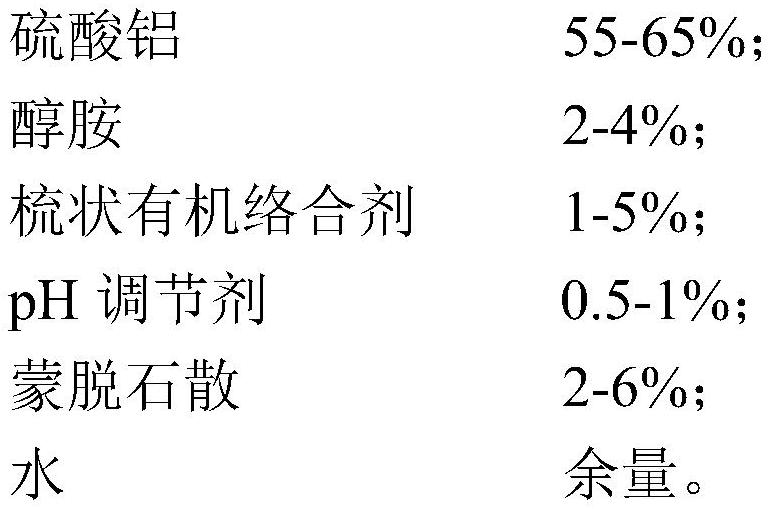

[0034] The liquid alkali-free quick-setting agent prepared by the ring-opening of the cyclic amide monomer in this embodiment includes the following components in mass percentage:

[0035]

[0036] The liquid alkali-free quick-setting agent prepared by the ring-opening of the cyclic amide monomer of this embodiment is prepared by the following method:

[0037] (1) The preparation of anion initiator: at first 50g cytosine, 6.9g magnesium bromide, 100g mass fraction are 5% dilute hydrochloric acid to join in the reactor, stir and be warming up to 40 ℃, continue feeding N 2 After protection and constant temperature reaction for 2 hours, the precipitate was filtered out, washed once with dilute hydrochloric acid with a mass fraction of 5%, and then the hydrochloric acid was removed by vacuum distillation to obtain an anionic initiator;

[0038] (2) Ring-opening polymerization: Add 100g of cytosine and 0.5g of 2,4-toluene diisocyanate into the reactor, stir and heat up to 60°C f...

Embodiment 2

[0042] The liquid alkali-free quick-setting agent prepared by the ring-opening of the cyclic amide monomer in this embodiment includes the following components in mass percentage:

[0043]

[0044]

[0045] The liquid alkali-free quick-setting agent prepared by the ring-opening of the cyclic amide monomer of this embodiment is prepared by the following method:

[0046] (1) The preparation of anionic initiator: at first 50g 5-methylcytosine, 5.7g magnesium bromide, 200g mass fraction are 10% dilute hydrochloric acid to join in the reactor, stir and be warming up to 45 ℃, continue feeding N 2 After protection and constant temperature reaction for 3 hours, the precipitate was filtered out, washed twice with dilute hydrochloric acid with a mass fraction of 10%, and then the hydrochloric acid was removed by vacuum distillation to obtain an anionic initiator;

[0047] (2) Ring-opening polymerization: Add 100g of 5-methylcytosine and 1g of 2,6-toluene diisocyanate into the rea...

Embodiment 3

[0051] The liquid alkali-free quick-setting agent prepared by the ring-opening of the cyclic amide monomer in this embodiment includes the following components in mass percentage:

[0052]

[0053]

[0054] The liquid alkali-free quick-setting agent prepared by the ring-opening of the cyclic amide monomer of this embodiment is prepared by the following method:

[0055] (1) The preparation of anionic initiator: at first 50g 5-fluorocytosine, 5.1g magnesium bromide, 300g mass fraction are 15% dilute hydrochloric acid to join in the reactor, stir and be warming up to 50 ℃, continue feeding N 2 After protection and constant temperature reaction for 4 hours, the precipitate was filtered out, washed 3 times with dilute hydrochloric acid with a mass fraction of 15%, and then decompressed to distill off the hydrochloric acid to obtain an anionic initiator;

[0056] (2) Ring-opening polymerization: Add 100g of 5-fluorocytosine and 1.5g of 1,6-hexamethylene diisocyanate into the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com