Method and device for aftertreatment of exhaust gases of internal combustion engines

一种废气后处理、内燃机的技术,应用在排气处理装置的电控、排气处理装置的诊断装置、排气装置等方向,能够解决未充分地考虑催化器转化性能等问题,达到提高寿命、有效废气后处理、小排放的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

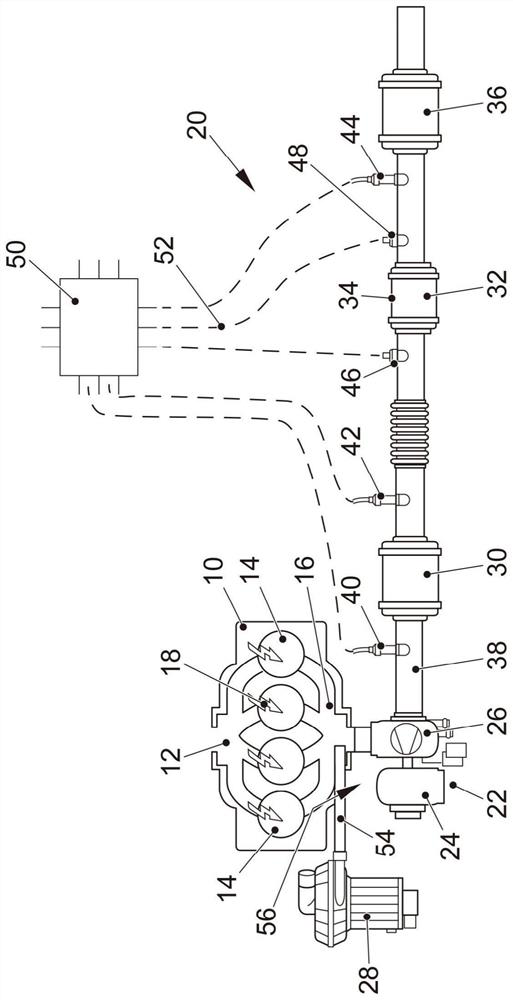

[0030] figure 1 An internal combustion engine 10 is shown, which is designed as a gasoline engine with external ignition by means of spark plugs 18 . Internal combustion engine 10 has an intake port 12 , a plurality of combustion chambers 14 and an exhaust port 16 . An exhaust port 16 of internal combustion engine 10 is connected to an exhaust system 20 . The internal combustion engine 10 is preferably designed as an internal combustion engine 10 supercharged by means of an exhaust gas turbocharger 22 . For this purpose, the exhaust gas turbocharger 22 has a turbine 26 arranged in the exhaust gas duct 38 of the exhaust system 20 , which drives a compressor 26 in the not shown air supply system of the internal combustion engine 10 and thus improves the combustion chamber 14 inflation status. In the exhaust gas channel 38, along the flow direction of the exhaust gas through the exhaust gas channel 38, a first three-way catalytic converter 30 is arranged downstream of the turb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com